- Recycled EV battery materials from Imperial College London outperform virgin materials in purity and performance, offering longer lifespan and reduced costs.

- The recycling of lithium iron phosphate batteries by Altilium strengthens the UK's green energy initiatives.

- The Munich-based startup tozero recycles graphite with over 80% efficiency, aiming to significantly increase production by 2030.

- Local graphite recovery enhances the resilience of battery production in Europe and reduces supply chain dependencies.

- Fellten in the UK cleverly converts used EV batteries into versatile and stackable energy storage solutions, advancing sustainable energy distribution.

- The industry's shift from a depletion economy to a circular economy in battery recycling fosters innovation and sustainability.

The dilemma of what to do with electric vehicle (EV) batteries at the end of their life has been a persistent challenge for the transport and energy sectors. Yet, a spark of innovation promises to redefine this narrative. A recent breakthrough from Imperial College London reveals a promising turning point: recycled EV battery materials can outperform their virgin counterparts.

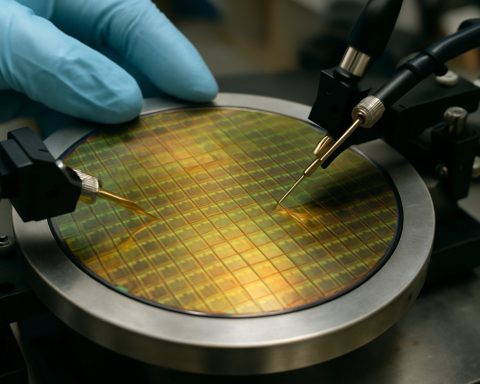

Researchers meticulously studied Altilium's recycled cathode active materials and discovered improvements in purity, morphology, and electrochemical performance. The implications are profound: expect longer battery life, faster charging times, and reduced costs. Meanwhile, Altilium has launched its lithium iron phosphate (LFP) battery recycling operations, bolstering the UK's green energy ambitions.

At the same time, tozero, a Munich-based startup, has begun ramping up the production of recycled graphite from EV batteries, demonstrating performance equivalent to virgin graphite. With over 80% recovery efficiency, tozero plans to produce over 2,000 tons by 2027, potentially exceeding 10,000 tons by 2030, thus significantly reducing reliance on distant supply chains.

Graphite remains a critical yet overlooked component in the EV battery space. Often overshadowed by metals like lithium and cobalt, it is essential for battery stability but is plagued by geopolitical vulnerabilities. By recovering graphite locally, Europe moves closer to a resilient circular economy in battery production.

Moreover, Fellten in the UK ingeniously repurposes second-life EV batteries into robust, stackable energy storage systems. Their Charge Qube solution places energy where it's needed, quickly and sustainably, meeting the demand for versatile energy solutions.

The landscape of EV battery recycling is transforming from a linear path of depletion to a circular journey of renewal and innovation, fueling a sustainable future.

Revolutionary Innovations in EV Battery Recycling to Know

Steps & Practical Tips for EV Battery Recycling

1. Identify Collection Points: Locate collection centers for end-of-life batteries. Many manufacturers offer take-back programs.

2. Partner with Certified Recyclers: Collaborate with certified recycling companies like Altilium and tozero to ensure proper treatment and material recovery.

3. Implement Second Life Solutions: Consider repurposing batteries for secondary uses such as home energy storage or in products like Fellten's Charge Qube.

4. Stay Informed on Developments: Follow industry developments to make informed decisions about battery disposal and recycling options.

Real-World Use Cases

– Improved Cathode Materials from Altilium: Offering enhanced battery performance, these materials support longer life and faster charging in new battery packs.

– Recycled Graphite from tozero: Manufacturers can integrate recovered graphite to reduce reliance on volatile supply chains, thereby enhancing sustainability.

– Charge Qube from Fellten: Second-life batteries power versatile, stackable storage systems, ideal for backup or remote energy needs.

Market Forecasts & Industry Trends

– The EV battery recycling market is expected to see significant growth driven by technological advancements and increased environmental awareness. Industry reports suggest an average growth rate of approximately 20% per year until 2030.

– Companies like Altilium and tozero will be at the forefront of sustainability trends, focusing on local resource recovery to enhance energy independence.

Opinions & Comparisons

– Recycled Materials vs. Virgin Materials: Preliminary studies from Imperial College London indicate superior performance of recycled materials, suggesting widespread adoption in the industry.

– Local Solutions vs. Imported Resources: European initiatives like tozero's offer a competitive advantage by reducing geopolitical risks associated with imported battery materials.

Controversies & Limitations

– Current Limitations: Recycling processes are energy-intensive and require significant technological advancements to become fully viable and sustainable at scale.

– Regulatory Challenges: Different countries have varied regulations, complicating international cooperation and standardization of recycling practices.

Safety & Sustainability

– The use of recycled materials like those from Altilium reduces environmental impact, as fewer raw materials need to be extracted, decreasing carbon emissions and habitat disruption.

– Local recycling enhances energy security by minimizing dependence on politically unstable regions for raw materials.

Overview of Advantages & Disadvantages

Advantages:

– Enhanced battery performance and longer lifespan.

– Reduced environmental impact from less extraction and waste.

– Increased energy security and reduced supply chain dependence.

Disadvantages:

– Current recycling processes may still be less efficient than desired.

– Varied regulatory environments could hinder streamlined operations.

Actionable Recommendations

– Adopt Sustainable Practices: Integrate recycled materials into product design to promote sustainability and potentially reduce costs.

– Encourage Political Support: Advocate for policies that incentivize recycling and harmonize international standards for better efficiency.

– Invest in R&D: For industry players, investing in technological solutions like those developed by Imperial College and startups like tozero can provide a competitive edge.

For the latest innovations in EV batteries, explore further at Imperial College London and Tesla for their cutting-edge approaches to energy technology.