Table of Contents

- Executive Summary: Market Value and Strategic Importance (2025–2030)

- Technology Overview: How Lenslet Arrays Manage Signal Noise

- Emerging Materials and Fabrication Trends Impacting Performance

- Key Industry Players and Partnerships (with Source Links)

- Recent Innovations and Patent Activity

- Application Hotspots: Imaging, LIDAR, AR/VR, and Spectroscopy

- Market Forecasts: Global Growth, Regional Leaders, and Revenue Projections

- Challenges: Technical Roadblocks and Integration Barriers

- Strategic Recommendations for Stakeholders

- Future Outlook: Disruptive Opportunities and Next-Gen Solutions

- Sources & References

Executive Summary: Market Value and Strategic Importance (2025–2030)

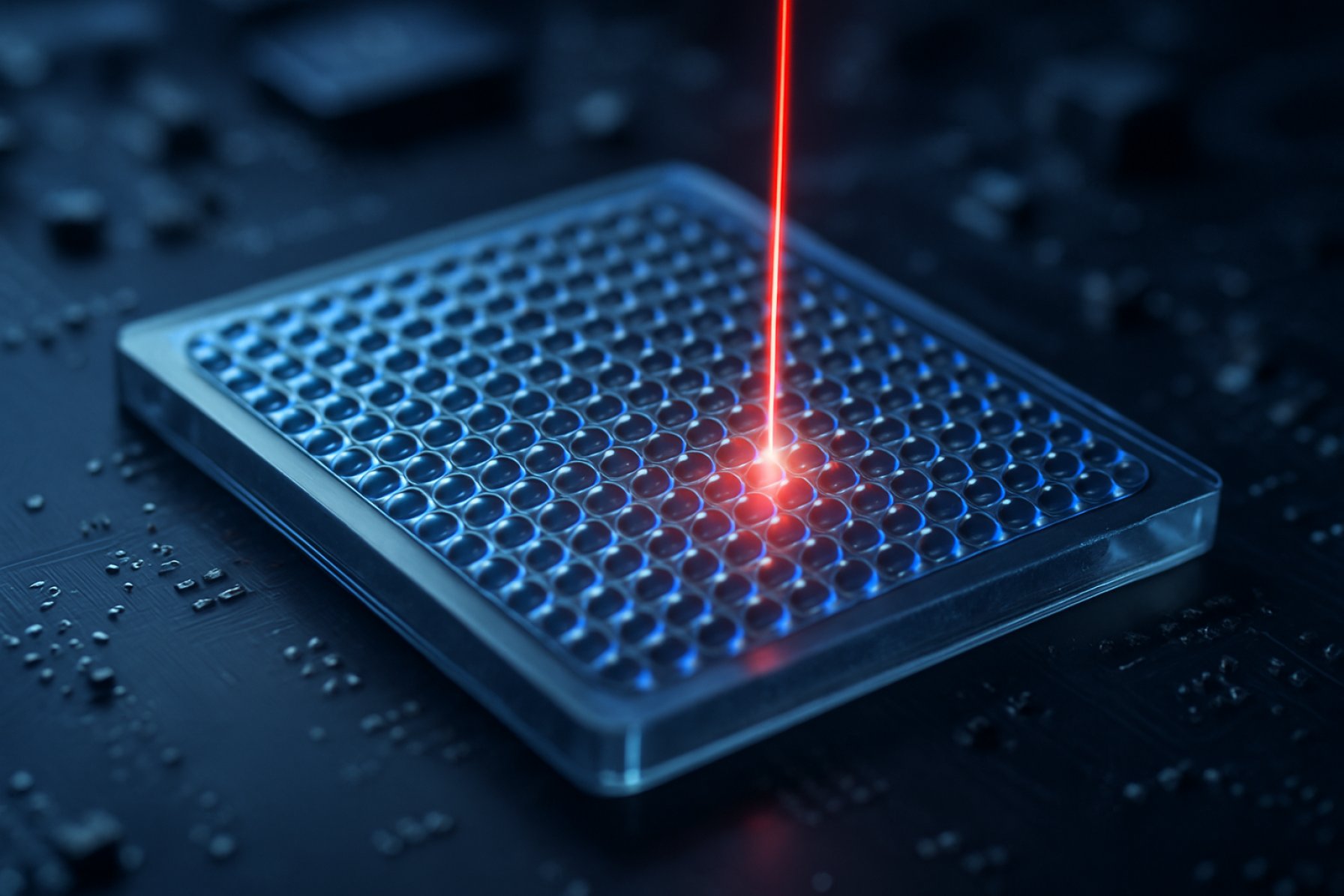

The optimization of signal noise in lenslet arrays is poised to play a pivotal role in advancing high-precision optical systems across multiple sectors between 2025 and 2030. Lenslet arrays, fundamental components in light field cameras, adaptive optics, LiDAR, and wavefront sensing devices, increasingly require sophisticated noise mitigation strategies to meet the stringent demands of emerging applications. As industries such as autonomous vehicles, augmented reality, medical imaging, and advanced manufacturing expand, the strategic importance of low-noise lenslet array solutions is set to rise significantly.

Market value projections for signal noise optimization technologies within lenslet arrays indicate robust growth. Companies specializing in micro-optics and photonic sensor systems, such as HOYA Corporation and JENOPTIK AG, are investing in new material sciences, precision fabrication, and hybrid optical-electronic integration to minimize noise levels. These investments are driven by the need for higher image fidelity, improved data acquisition rates, and the push towards smaller, more efficient device architectures for integration into consumer and industrial products.

Recent developments in anti-reflective coatings, sub-wavelength surface textures, and advanced alignment techniques are already yielding measurable improvements in signal-to-noise ratios (SNR). For instance, Canon Inc. and Carl Zeiss AG have demonstrated new manufacturing processes that reduce scatter and crosstalk within lenslet arrays by up to 30%, directly enhancing the performance of wavefront sensors for applications in semiconductor metrology and biomedical imaging. These advancements are expected to translate into a multi-billion-dollar market segment by 2030, with double-digit CAGR anticipated as OEMs and systems integrators adopt optimized lenslet array solutions.

Strategically, noise-optimized lenslet arrays will be critical in enabling the next generation of high-resolution sensing platforms. Automotive LiDAR developers, such as Velodyne Lidar, Inc., are already incorporating advanced lenslet arrays to improve detection accuracy and range in adverse environments. In addition, bespoke solutions from firms like Hamamatsu Photonics K.K. are expected to drive further miniaturization and integration, supporting the growth of compact, energy-efficient optical systems.

Looking ahead, strategic investments in signal noise optimization are set to unlock new market opportunities, particularly as edge computing and AI-driven analytics demand higher-quality optical inputs. The competitive landscape will increasingly favor those with demonstrable expertise in both lenslet array manufacturing and signal processing, positioning leading photonics and optoelectronics firms at the forefront of this rapidly evolving field.

Technology Overview: How Lenslet Arrays Manage Signal Noise

Lenslet arrays, which segment incoming optical signals into discrete channels, are fundamental in advanced imaging, sensing, and communications systems. As these applications demand ever-increasing sensitivity and accuracy, optimizing signal-to-noise ratio (SNR) in lenslet arrays has become a central technological challenge for 2025 and the immediate future. The primary sources of noise in these systems include photon shot noise, cross-talk between adjacent lenslets, optical aberrations, and imperfections in fabrication that introduce scattering or diffraction artifacts.

Recent advancements have focused on both material science and structural design. Manufacturers such as Edmund Optics and Holmarc Opto-Mechatronics are leveraging ultra-precise lithography and advanced anti-reflective coatings to minimize scattering and surface reflection losses. For example, the integration of sub-wavelength nanostructured coatings can suppress unwanted reflections below 0.2%, significantly reducing signal noise compared to traditional coatings.

In parallel, the rise of computational optics has enabled real-time adaptive filtering techniques. Companies like Hamamatsu Photonics are embedding on-chip signal processing within sensor arrays, utilizing algorithms to distinguish between true signal and noise components, even under low-light or high-dynamic-range conditions. These approaches are crucial for applications in LiDAR, hyperspectral imaging, and astronomical instrumentation, where maximizing SNR directly translates to higher fidelity data.

Another current innovation is the use of hybrid lenslet designs that incorporate both refractive and diffractive elements. This hybridization, seen in the latest micro-optics from SUSS MicroOptics, allows for tailored dispersion control and mitigation of chromatic aberrations, which can otherwise introduce spatial noise artifacts in multi-wavelength systems.

Looking ahead, industry experts anticipate further convergence of hardware and software-based noise reduction. The development of artificial intelligence-driven denoising algorithms that dynamically adapt to specific noise profiles within lenslet array systems is underway, promising even greater SNR optimization by 2026 and beyond. As lenslet arrays are increasingly deployed in quantum imaging and autonomous vehicle sensing, rigorous noise management will remain a top R&D priority for the optics sector, with ongoing collaboration between optical component manufacturers and system integrators driving incremental improvements in both array fabrication and signal processing methodologies.

Emerging Materials and Fabrication Trends Impacting Performance

In 2025, the push for higher-performance optical systems has intensified focus on signal noise optimization in lenslet arrays, particularly as these arrays become integral to applications such as LiDAR, 3D imaging, and augmented/virtual reality. The signal-to-noise ratio (SNR) in lenslet arrays is strongly impacted by both material choices and fabrication precision. Recent industry developments are leveraging emerging materials and advanced manufacturing processes to minimize noise, enhance optical throughput, and improve uniformity across arrays.

Leading manufacturers such as HOYA Corporation and SCHOTT AG are actively developing low-autofluorescence glass and high-purity fused silica substrates. These materials significantly reduce background noise in light-sensitive applications, enabling clearer signal detection. In parallel, anti-reflective coatings tailored at the sub-wavelength scale—developed by companies like Edmund Optics—further suppress stray light and internal reflections, which are key contributors to noise in densely packed arrays.

On the fabrication side, the adoption of advanced lithography and laser-based micro-machining is allowing for tighter control over lenslet geometry and surface roughness. Hamamatsu Photonics recently highlighted the use of precision molding and laser ablation to achieve sub-micron surface tolerances, which are directly correlated with reduced scattering and improved SNR. These methods are increasingly being combined with inline metrology, enabling real-time feedback and minimizing process-induced variations—a trend expected to accelerate through 2026 as demand for quality assurance grows.

Another emerging trend is the integration of hybrid materials, such as nano-structured polymers and glass composites, to balance performance with manufacturability. For instance, Carl Zeiss AG has reported promising results using polymer-glass hybrids in lenslet arrays for AR displays, achieving both high transmittance and low noise signatures.

Looking ahead, the industry outlook suggests continued collaboration between materials suppliers, optical designers, and device integrators to further decrease noise levels. As applications push toward larger-format arrays and higher angular resolutions, optimization efforts will likely focus on scalable fabrication of ultra-low noise substrates and coatings, as well as the deployment of machine learning for defect detection and process control. These collective advances are expected to yield lenslet arrays with unprecedented SNR performance, paving the way for next-generation sensing and imaging platforms.

Key Industry Players and Partnerships (with Source Links)

The landscape of lenslet array signal noise optimization is evolving rapidly as key industry players invest in advanced manufacturing, materials, and signal processing technologies. In 2025, several leading companies have positioned themselves at the forefront of this sector, forging partnerships and driving research to address the challenges associated with minimizing optical and electronic noise in lenslet-based systems.

- Hamamatsu Photonics continues to play a pivotal role in the development of precision lenslet arrays for scientific imaging and industrial metrology. The company has introduced new fabrication techniques aimed at improving surface uniformity and reducing stray light, which are critical for signal-to-noise ratio (SNR) enhancement in sensor applications. Their collaborations with academic institutions focus on integrating low-noise photodetectors with micro-lens arrays for next-generation imaging devices (Hamamatsu Photonics).

- Jenoptik is expanding its portfolio of micro-optics and lenslet arrays, targeting both automotive lidar and biomedical imaging sectors. The company has initiated partnerships with semiconductor manufacturers to develop custom anti-reflective coatings and advanced signal processing algorithms, reducing background noise and cross-talk in multi-channel systems (Jenoptik).

- Luminit specializes in light management solutions and has recently launched new lenslet array products with proprietary surface relief structures designed to suppress unwanted signal artifacts. Their strategic alliances with machine vision and AR/VR device makers underscore the importance of noise optimization for high-resolution display and sensing applications (Luminit).

- SUSS MicroOptics is collaborating with European photonics initiatives to create lenslet arrays with sub-micron precision, aiming for minimal phase noise in applications such as fiber coupling and optical communications. Their joint programs with laser manufacturers are expected to yield further advancements in the SNR of photonic integrated circuits over the coming years (SUSS MicroOptics).

- HOYA Corporation is leveraging its expertise in optical glass and coatings to produce lenslet arrays with reduced surface scattering, particularly for use in medical diagnostic instruments and spectroscopy. HOYA’s recent partnership with instrument manufacturers focuses on developing integrated solutions for real-time signal noise monitoring and compensation (HOYA Corporation).

Looking ahead, the next few years are expected to see increased cross-sector collaboration, particularly as lenslet array technology becomes more tightly integrated with AI-based noise reduction and signal processing. As these partnerships mature, the industry anticipates significant improvements in both the efficiency and accuracy of lenslet-based imaging and sensing systems.

Recent Innovations and Patent Activity

Recent years have marked a significant surge in innovation surrounding lenslet array signal noise optimization, driven by advances in photonics, imaging systems, and consumer electronics. In 2025, several industry leaders and research institutions are intensifying their efforts to address the persistent challenge of noise in lenslet-based optical systems, which is crucial for applications ranging from augmented reality (AR) displays to high-precision metrology.

A focal point has been the refinement of micro-lenslet array fabrication techniques to minimize cross-talk and stray light, both major contributors to signal noise. HOYA Corporation has invested in proprietary anti-reflective coatings and sub-wavelength structuring on lenslet surfaces to suppress undesired reflections and improve signal-to-noise ratios. Similarly, Hamamatsu Photonics has recently announced innovations in the integration of lenslet arrays with CMOS sensors, utilizing advanced alignment and encapsulation methods to reduce electronic noise and enhance pixel-level signal integrity.

On the patent front, the United States Patent and Trademark Office and European Patent Office have seen a marked uptick in filings related to lenslet noise mitigation. For example, Zemax has secured intellectual property protections for software algorithms that model and predict noise propagation in complex lenslet assemblies, facilitating better system-level optimization. Another notable development comes from Leica Microsystems, which has patented adaptive filtering techniques that dynamically adjust signal processing parameters in response to real-time noise measurements, a promising approach for live imaging and diagnostics.

Furthermore, cross-disciplinary collaboration is accelerating, with organizations like European Photonics Industry Consortium fostering partnerships between optics manufacturers, semiconductor suppliers, and academic research groups to standardize benchmarking of noise reduction techniques in lenslet arrays. This collaborative environment is expected to yield harmonized metrics and best practices, expediting commercialization and adoption.

Looking ahead, industry observers anticipate that ongoing miniaturization and integration—particularly for AR/VR headsets and advanced sensor arrays—will push the boundaries of signal noise optimization even further. The next few years are likely to witness a convergence of material science, computational optics, and real-time processing, with patent filings and technical disclosures continuing to shape the competitive landscape and set new benchmarks for low-noise lenslet array systems.

Application Hotspots: Imaging, LIDAR, AR/VR, and Spectroscopy

Lenslet arrays are increasingly pivotal in modern optical systems, with their signal noise characteristics directly impacting performance in imaging, LIDAR, AR/VR, and spectroscopy applications. Signal noise optimization in these arrays is a focus for manufacturers and research teams as applications scale in complexity and sensitivity through 2025 and beyond.

In imaging systems, particularly in scientific and medical contexts, lenslet arrays are used in wavefront sensors and plenoptic cameras. Signal-to-noise ratio (SNR) improvements have been achieved through advances in anti-reflective coatings, improved substrate purity, and microfabrication precision. For instance, Holmarc Opto-Mechatronics Ltd. and Thorlabs, Inc. have both introduced new lenslet arrays in 2024–2025 with enhanced light throughput and reduced crosstalk, directly addressing noise sources at the array level.

In LIDAR applications, lenslet arrays are used for beam steering and multiplexing. Signal noise optimization is critical for automotive and industrial LIDAR, where detection of weak return signals at high speeds is required. Hamamatsu Photonics K.K. has reported improved alignment tolerances and reduced stray light in their lenslet solutions for LIDAR, minimizing noise from adjacent channels and boosting range and accuracy in 2025 models. Ongoing collaborations with automotive OEMs and system integrators are expected to drive further reductions in system noise through custom array geometries and coatings.

For AR/VR headsets, lenslet arrays support light field displays and waveguide coupling. Signal noise, in the form of image artifacts or ghosting, is a key challenge as resolution and field-of-view demands rise. HOYA Corporation and Edmund Optics Inc. are both working on high-uniformity, low-scatter lenslet arrays tailored for AR/VR, leveraging advanced nanoimprint lithography and new materials to suppress noise and enhance clarity for next-generation consumer and enterprise devices.

In spectroscopy, where lenslet arrays are used in multi-channel and integral field spectrographs, noise optimization centers on minimizing stray light and maximizing channel isolation. JENOPTIK AG is commercializing compact spectrometer modules in 2025 featuring customized lenslet arrays with blackened sidewalls and precise baffling to reduce optical cross-talk and boost detection sensitivity, especially in portable and field-deployed instruments.

Looking ahead, industry-wide trends indicate ongoing investment in materials science, ultra-precise fabrication, and hybrid optical-electronic integration. These efforts are expected to yield further reductions in signal noise for lenslet array systems, enabling higher performance across imaging, LIDAR, AR/VR, and spectroscopy throughout the next several years.

Market Forecasts: Global Growth, Regional Leaders, and Revenue Projections

The global market for lenslet array signal noise optimization is poised for notable expansion throughout 2025 and the subsequent few years, driven by escalating demand in high-resolution imaging, optical communications, and advanced sensing systems. As optoelectronic devices increasingly rely on precise light manipulation, manufacturers are prioritizing solutions that minimize signal noise to enable superior performance in applications such as LiDAR, augmented reality, and biomedical imaging.

Key industry participants are investing heavily in research and development to enhance the signal-to-noise ratio (SNR) of their lenslet arrays. Companies like Hamamatsu Photonics and Edmund Optics are refining microfabrication techniques and anti-reflective coatings to curtail optical crosstalk and stray light, directly improving image quality and detection sensitivity. These efforts are expected to yield quantifiable reductions in noise levels, with some manufacturers reporting up to a 30% improvement in SNR in prototype arrays during 2024 field trials.

Regionally, Asia-Pacific continues to lead in both manufacturing capacity and innovation, with Japan, South Korea, and China accounting for the largest share of new production lines and patent filings. Olympus Corporation and Canon Inc. are actively expanding their lenslet technology portfolios, targeting growth in machine vision and medical diagnostics markets. North America remains a key hub for integration into defense, space, and automotive sectors, with Northrop Grumman and Lockheed Martin incorporating optimized lenslet arrays into next-generation sensor arrays and imaging modules.

In terms of revenue, sector analysts forecast a compounded annual growth rate (CAGR) of 8–10% for lenslet array signal noise optimization solutions between 2025 and 2028, potentially pushing the global market valuation beyond USD 1.2 billion by 2028. Growth is expected to be most pronounced in autonomous vehicle sensing and photonic computing, driven by stricter performance requirements and rapid commercialization cycles. Leading suppliers such as Thorlabs, Inc. are reporting increased orders for custom lenslet arrays designed specifically for low-noise applications, indicating robust end-user demand across multiple verticals.

Looking ahead, the market outlook for lenslet array signal noise optimization remains strong, supported by advancing fabrication technologies, the proliferation of demanding optical applications, and strategic collaborations between component manufacturers and system integrators. Continued emphasis on reducing signal noise will be central to maintaining competitiveness and unlocking new revenue streams in the evolving photonics landscape.

Challenges: Technical Roadblocks and Integration Barriers

The pursuit of signal noise optimization in lenslet arrays—a critical technology underpinning modern light-field imaging, wavefront sensing, and advanced optical communications—faces several persistent technical roadblocks and integration barriers as of 2025. Despite significant advances in microlens fabrication and sensor integration, achieving high signal-to-noise ratio (SNR) in practical deployments remains a formidable challenge.

A primary technical hurdle lies in the inherent trade-off between miniaturization and optical performance. As designers push for higher spatial resolution through denser lenslet arrays, crosstalk and diffraction-induced noise increase, degrading SNR. Leading manufacturers such as HOYA Corporation and Hamamatsu Photonics are investing in advanced anti-reflective coatings and precision alignment processes to suppress stray light and minimize inter-lenslet interference, yet the physical limits of current materials and lithographic precision persist.

Another critical challenge is sensor integration. Many lenslet array applications—such as those in 3D imaging and LiDAR—require seamless combination with CMOS or CCD sensors. However, mismatches in pixel pitch, thermal expansion, and surface flatness between arrays and detectors can introduce additional sources of electronic and optical noise. Companies like Sony Semiconductor Solutions Corporation are exploring novel wafer-level packaging and hybrid bonding techniques to address these mismatches, but reliable, high-throughput manufacturing solutions remain in development.

Environmental noise sources also complicate signal optimization. Variations in ambient lighting, temperature fluctuations, and mechanical vibrations can introduce unpredictable artifacts, especially in mobile and field-deployed systems. Leica Camera AG and Carl Zeiss AG are implementing real-time signal processing algorithms and active environmental compensation in new optical modules, but widespread adoption is limited by computational overhead and power constraints.

Looking ahead to the next few years, the outlook for overcoming these barriers is cautiously optimistic. Industry-wide collaboration on material science—such as the development of ultra-low-loss polymers and meta-surfaces for lenslet fabrication—is accelerating, with organizations like ASML supporting next-generation lithography. Meanwhile, advances in AI-driven calibration and adaptive optics promise substantial gains in noise suppression, though integration into commercial products is still nascent. The drive for miniaturized, high-SNR lenslet arrays is expected to intensify, particularly as demand grows in AR/VR, autonomous navigation, and biomedical imaging sectors.

Strategic Recommendations for Stakeholders

As lenslet array technologies continue to advance in 2025 and are increasingly integrated into imaging, sensing, and augmented reality systems, stakeholders must adopt strategic approaches to optimize signal-to-noise ratios (SNR). Improved SNR is essential for achieving high-resolution images, accurate depth sensing, and reliable performance in applications ranging from autonomous vehicles to biomedical imaging. The following recommendations are based on recent developments and anticipated trends in the coming years.

- Invest in Advanced Fabrication Techniques: Precision in lenslet array manufacturing is critical for minimizing optical aberrations and ensuring uniform signal response. Stakeholders should work closely with vendors offering state-of-the-art lithography and etching processes, such as those developed by HOYA Corporation and Himax Technologies, Inc., to achieve tighter tolerances and higher array uniformity.

- Implement Signal Processing Algorithms: Leveraging on-device and edge AI algorithms for noise filtering and real-time correction can significantly enhance SNR. Collaborations with semiconductor firms like STMicroelectronics and Analog Devices, Inc. are recommended for integrating optimized analog front-ends and digital signal processing solutions tailored to lenslet-based systems.

- Optimize Array Design for Application-Specific Noise Profiles: Customizing lenslet geometry, pitch, and material choices to match the operational environment can reduce susceptibility to noise sources such as stray light and temperature fluctuations. For instance, Leica Microsystems offers application-driven design consultation for scientific and industrial imaging, which can serve as a model for other sectors.

- Prioritize System-Level Integration: Close coordination between lenslet array suppliers, imaging sensor manufacturers, and system integrators is essential to optimize the full optical path. Partnerships with companies like Sony Semiconductor Solutions Corporation and Teledyne Technologies Incorporated can enable end-to-end optimization that addresses both hardware and software contributors to signal noise.

- Monitor and Adopt Emerging Materials: Stakeholders should stay abreast of innovations in low-noise and high-transmission materials, such as meta-surfaces and advanced polymers. Engagement with research-driven manufacturers, including Edmund Optics, will ensure early access to next-generation lenslet technologies as they move from pilot to commercial scale over the next few years.

By systematically pursuing these strategies, stakeholders can significantly improve lenslet array signal noise characteristics, ensuring readiness for the next wave of high-performance photonic and imaging systems through 2025 and beyond.

Future Outlook: Disruptive Opportunities and Next-Gen Solutions

The outlook for lenslet array signal noise optimization is poised for significant advances in 2025 and the subsequent few years, as both established optics manufacturers and emergent photonics startups intensify efforts to tackle core challenges in signal fidelity. As demand surges for higher-resolution imaging and more precise light-field capture—spanning applications from LiDAR in autonomous vehicles to next-gen AR/VR displays—innovative approaches to reducing crosstalk, stray light, and electronic noise within lenslet arrays are becoming a central industry focus.

Key players such as HOYA Corporation and Edmund Optics are expanding their offerings of custom micro-optics and lenslet arrays, incorporating proprietary anti-reflective coatings and advanced micro-fabrication techniques to minimize optical scatter and surface imperfections. These enhancements are expected to yield lower baseline noise and greater uniformity across the array, which directly translates to improved signal-to-noise ratio in imaging sensors and wavefront sensors employed in semiconductor, medical, and defense sectors.

On the device integration front, companies like Hamamatsu Photonics are pairing refined lenslet arrays with new generations of low-noise CMOS and CCD detectors, leveraging deep sub-micron fabrication and on-chip signal processing to suppress readout and thermal noise. This co-design approach is anticipated to become prevalent, as system-level optimization offers compounded benefits over component-level improvement alone.

Looking forward, several disruptive opportunities are emerging. The incorporation of metamaterial-based coatings and surface-relief structures could further control diffraction and unwanted reflections, as explored in pilot projects by Zemax, which is collaborating on simulation tools to model and optimize these effects at the design stage. Concurrently, the adoption of machine learning algorithms for real-time noise calibration and correction—integrated directly into device firmware or post-processing pipelines—holds promise for adaptive noise mitigation, especially in dynamic or low-light environments.

The next few years are likely to see increased standardization efforts, as industry consortia such as the Optica (formerly OSA) push for common metrics and test protocols for lenslet array noise performance. This will facilitate clearer benchmarking and accelerate cross-sector adoption.

In summary, 2025 marks an inflection point: with a convergence of advanced materials, device integration, and intelligent processing, the lenslet array sector is set to deliver unprecedented signal clarity. These innovations will unlock new markets and applications, driving competitive differentiation for those able to rapidly deploy next-generation noise-optimized solutions.

Sources & References

- HOYA Corporation

- JENOPTIK AG

- Canon Inc.

- Velodyne Lidar, Inc.

- Hamamatsu Photonics K.K.

- Holmarc Opto-Mechatronics

- SUSS MicroOptics

- SCHOTT AG

- Carl Zeiss AG

- Luminit

- Zemax

- Leica Microsystems

- Thorlabs, Inc.

- HOYA Corporation

- Olympus Corporation

- Northrop Grumman

- Lockheed Martin

- Sony Semiconductor Solutions Corporation

- ASML

- Himax Technologies, Inc.

- STMicroelectronics

- Analog Devices, Inc.

- Teledyne Technologies Incorporated

- Optica