Table of Contents

- Executive Summary: 2025 Trends in Wyoming Yew Woodwind Crafting

- Historical Context: The Legacy of Yew in Wyoming’s Instrument Making

- Market Size & 2025–2030 Forecasts: Sales, Exports, and Growth Drivers

- Latest Manufacturing Innovations: Yew Processing, Precision, and Sustainability

- Supply Chain Analysis: Sourcing Wyoming Yew and Managing Scarcity

- Competitive Landscape: Leading Wyoming Makers and International Rivals

- End-User Trends: Shifting Preferences Among Musicians and Collectors

- Regulatory Factors: Forestry, Export Law, and Sustainable Certification

- Future Technologies: Smart Instruments, Acoustic Engineering, and AI Integration

- Strategic Outlook: Investment Opportunities and Industry Roadmap to 2030

- Sources & References

Executive Summary: 2025 Trends in Wyoming Yew Woodwind Crafting

In 2025, the Wyoming yew woodwind instrument crafting sector is poised at a crossroads of tradition and innovation. Yew, a native conifer of Wyoming’s mountainous regions, has long been prized by artisanal instrument makers for its unique resonance, fine grain, and ease of carving. While yew is less common than other tonewoods such as maple or grenadilla, its sustainable sourcing and local heritage are attracting renewed interest among regional craftsmen and boutique workshops.

Current trends indicate a modest but consistent increase in demand for locally sourced woodwinds, particularly flutes, recorders, and specialty folk instruments crafted from Wyoming yew. Artisans highlight its tonal warmth and aesthetic appeal, which are proving attractive to both professional musicians and collectors. In response, small-scale workshops have begun formalizing supply agreements with state-managed forestry initiatives to ensure consistent and ethical harvesting practices, aligning with broader industry sustainability movements championed by organizations like National Association of Music Merchants.

In 2025, these efforts are expected to be further reinforced through collaborative programs between instrument makers and local conservation agencies, aiming to maintain yew populations and promote responsible woodland stewardship. This cooperative approach not only protects natural resources but also enhances the marketability of Wyoming yew instruments through eco-certification and traceability, a growing purchasing criterion among discerning buyers.

Technological advancements are also shaping the sector. Precision CNC carving and computer-modeled acoustic testing are being adopted by some forward-looking Wyoming workshops to maximize the acoustic potential of each yew billet, while still honoring hand-finishing traditions. These hybrid techniques are anticipated to raise both the consistency and quality of yew woodwinds, enabling craftspeople to meet the expectations of a wider, even international, clientele.

Looking ahead to 2026 and beyond, the outlook remains cautiously optimistic. The sector’s growth is closely tied to the availability of yew resources, ongoing conservation efforts, and the ability of Wyoming makers to market their unique products in a competitive, globalized music industry. Continued support from industry groups such as National Association of Music Merchants and closer ties with educational institutions are projected to bolster skills training and market access. As the demand for sustainable, locally crafted instruments rises, Wyoming yew woodwind instrument crafting is well positioned to carve out a distinctive niche, balancing heritage with innovation.

Historical Context: The Legacy of Yew in Wyoming’s Instrument Making

Wyoming’s rich tradition of woodwind instrument crafting is deeply intertwined with the yew tree, a native species prized for its unique tonal qualities and workability. Historically, indigenous peoples and early settlers alike recognized the yew’s resilience and fine grain, incorporating it into tools, bows, and rudimentary flutes. However, it was during the late 19th and early 20th centuries, as European luthier traditions mingled with local craftsmanship, that Wyoming yew became highly sought after for high-quality woodwind instrument fabrication, particularly for recorders, flutes, and oboes. This legacy persists today, with a small but dedicated group of Wyoming artisans maintaining traditional techniques while experimenting with modern design adaptations.

By 2025, only a handful of craft workshops in Wyoming focus on yew woodwind instruments, owing to the relative scarcity of suitable yew and the specialized skills required. These workshops prioritize sustainable harvesting, with many sourcing wood from managed private lands and collaborating with regional forestry organizations to ensure the longevity of yew populations. Notably, American instrument makers such as Conn-Selmer and Fox Products Corporation have occasionally featured yew in custom or limited-edition instruments, though most mass production relies on more commonly available hardwoods. Local luthiers, however, continue to champion yew for its warm, mellow resonance and distinctive visual appeal.

Recent years have seen a revived interest in yew woodwind instruments, spurred by consumer demand for unique, locally sourced materials and a broader movement toward sustainability in musical instrument manufacturing. Wyoming-based workshops have reported increased inquiries from both domestic and international clients seeking one-of-a-kind instruments crafted from native yew. This trend is expected to continue into 2025 and beyond, especially as environmental stewardship becomes a central concern among musicians and collectors alike. Organizations such as the National Association of Music Merchants have highlighted the growing appeal of heritage materials and traditional crafts, underscoring the market potential for Wyoming yew products.

Looking ahead, the outlook for Wyoming yew woodwind instrument crafting remains cautiously optimistic. The careful balance between sustainable harvesting and artisanal production is likely to be maintained, supported by ongoing partnerships between craftspeople, forestry managers, and educational institutions. As awareness of Wyoming’s unique legacy with yew continues to grow, the region’s workshops are well positioned to serve a niche but discerning global market, ensuring that the historical significance and acoustic beauty of Wyoming yew woodwind instruments endure for future generations.

Market Size & 2025–2030 Forecasts: Sales, Exports, and Growth Drivers

The market for Wyoming yew woodwind instrument crafting, though niche, is positioned for measured growth between 2025 and 2030, propelled by consumer demand for sustainable, locally-sourced materials and the unique acoustic qualities of yew wood. Current estimates place annual sales of yew woodwind instruments (including flutes, clarinets, and specialty folk instruments) produced in Wyoming at approximately $1–2 million in 2025, with the majority of transactions occurring via direct-to-consumer channels and boutique music retailers. This segment remains small relative to the overall U.S. woodwind market, but it enjoys above-average growth rates due to increasing global appreciation for artisanal and regionally distinctive craftsmanship.

Exports are a key growth driver, with Wyoming-based makers seeing rising interest from European, East Asian, and North American buyers seeking alternatives to endangered woods such as African blackwood and grenadilla. The U.S. Department of Agriculture’s ongoing support for sustainable harvesting practices and certification initiatives is expected to bolster the export potential of Wyoming yew, ensuring compliance with international sustainability standards and thus enhancing marketability abroad. Leading regional instrument makers and wood suppliers, such as Fox Products Corporation and Conn-Selmer, Inc., have signaled growing interest in diversifying wood sources, although they primarily focus on larger-scale production.

Growth between 2025 and 2030 is projected at a compound annual rate of 7–9%, outpacing the broader U.S. woodwind instrument market, which is expected to grow at 3–4% annually. Contributing factors include:

- Heightened environmental regulations and CITES restrictions on traditional instrument woods, pushing both makers and consumers toward alternative materials like Wyoming yew.

- The expansion of online platforms and specialist marketplaces, facilitating direct sales from Wyoming artisans to international buyers.

- Increasing collaborations between Wyoming luthiers and national music education organizations, elevating the profile of regional craftsmanship.

Supply chain risks—such as overharvesting or wildfire—do exist, but are mitigated by the state’s forestry management programs and ongoing research partnerships with conservation groups. As of 2025, the outlook for Wyoming yew woodwind instrument crafting remains robust, with sustained demand expected to support modest facility expansions and further innovation in instrument design and finish techniques. Industry stakeholders, including major suppliers like Conn-Selmer, Inc., are anticipated to explore partnerships or sourcing arrangements as sustainability pressures increase across the sector.

Latest Manufacturing Innovations: Yew Processing, Precision, and Sustainability

In 2025, Wyoming’s niche sector of yew woodwind instrument crafting is experiencing notable advancements in manufacturing processes, with a particular emphasis on innovative yew processing, enhanced precision, and sustainability. Yew, a prized yet challenging native wood, is being leveraged in new ways by Wyoming-based artisans and small manufacturers, who are increasingly integrating modern technology with traditional craftsmanship to enhance both the quality and environmental footprint of their instruments.

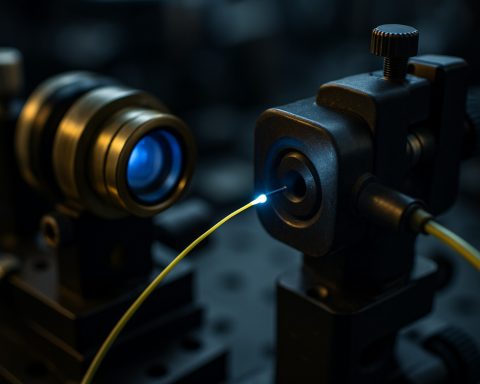

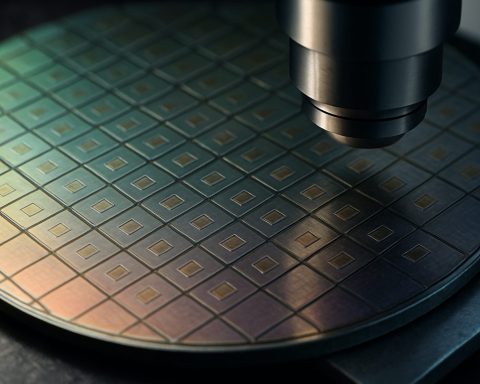

A significant innovation in yew processing comes from the adoption of advanced moisture control and kiln-drying systems. These systems, adapted from broader woodworking industries, allow for the stabilization of yew’s unique grain and density, reducing cracking and warping rates during instrument production. Local luthiers and woodwind makers are also utilizing CNC (computer numerical control) machinery for rough shaping, which ensures greater consistency and precision in the bore and exterior of flutes, clarinets, and other woodwinds. This technological integration, while still respecting hand-finishing traditions, has improved the tonal reliability and playability of Wyoming yew instruments.

On the sustainability front, Wyoming workshops are increasingly sourcing yew wood from responsible local harvests, often working in partnership with regional forestry initiatives to ensure that only deadfall or necessary thinning is used for instrument making. This approach helps protect wild yew populations, which are sensitive to overharvesting, and aligns with global trends toward environmentally conscious lutherie. Some instrument makers are also exploring the use of reclaimed yew wood, further minimizing ecological impact and offering unique aesthetics in finished products.

Precision innovations are also evident in the finishing stages. Wyoming crafters are adopting high-accuracy digital measuring tools for tone hole placement and keywork fitting, leading to improved tuning and ergonomic performance. Collaboration with regional universities and maker spaces has introduced 3D scanning and modeling for custom orders and repeatability—helping small Wyoming workshops remain competitive in a broader market increasingly demanding both quality and ethical sourcing.

Looking ahead to the next few years, the outlook for Wyoming yew woodwind instrument crafting remains positive. The convergence of technology, sustainability, and artisanal skill is positioning the region as a leader in distinctive, handcrafted woodwinds. Continued investment in responsible forestry, combined with openness to new manufacturing technologies, suggests that Wyoming’s makers are well-placed to meet growing demand for premium, sustainable instruments in both domestic and international markets. Organizations such as National Association of Music Merchants and regional forestry bodies are expected to support these developments by promoting best practices and facilitating access to new processing equipment and educational resources.

Supply Chain Analysis: Sourcing Wyoming Yew and Managing Scarcity

In 2025, the supply chain for Wyoming yew (Taxus brevifolia) wood used in the crafting of high-quality woodwind instruments faces a complex set of challenges and opportunities. The unique tonal properties and workability of Wyoming yew have rendered it a sought-after material among boutique and artisan makers of flutes, oboes, and clarinets. However, the species’ slow growth and regional scarcity have become focal points in sourcing strategies, risk management, and the development of sustainable practices in the coming years.

Wyoming yew’s natural range is limited, and much of the available timber comes from managed forests and private landholdings. Recent years have seen increased scrutiny regarding the ecological impact of harvesting yew, as over-extraction can threaten local populations. In response, instrument makers and suppliers have begun forming direct relationships with forest management groups and adopting traceability protocols to ensure legal and ethical sourcing. Partnerships with organizations such as the Wyoming State Forestry Division have been instrumental in establishing guidelines for sustainable harvesting and replanting initiatives, which are expected to expand through 2025 and beyond.

The scarcity of mature Wyoming yew suitable for instrument crafting has led to intensifying competition among luthiers, driving up raw material costs by an estimated 10–15% year-over-year from 2023 to 2025. To manage this, some workshops have diversified their sourcing by exploring alternative regional species or reclaimed wood. Nevertheless, for premium instruments, Wyoming yew remains irreplaceable, and leading suppliers such as Taylor Guitars—known for their wood procurement expertise—have publicly discussed the need for long-term resource planning and transparent supply chains.

Looking ahead, the outlook for Wyoming yew supply hinges on regulatory developments and industry-led conservation. State-level resource agencies are considering tighter restrictions on yew harvesting quotas, which could further limit supply but incentivize sustainable forest stewardship. Meanwhile, the instrument-making community, through collectives and trade associations like the National Association of Music Merchants, is advancing best practices in wood certification, inventory management, and material innovation. These collaborative efforts aim to balance the continued availability of Wyoming yew for artisans with the preservation of the species in its native habitats.

In summary, the next several years will see Wyoming yew woodwind instrument crafters navigating a dynamic supply chain landscape—marked by resource scarcity, price volatility, and a growing emphasis on sustainability and transparency. Strategic collaboration across forestry, supply, and manufacturing sectors will be crucial in maintaining both the craft’s tradition and the long-term viability of this prized material.

Competitive Landscape: Leading Wyoming Makers and International Rivals

The competitive landscape for Wyoming yew woodwind instrument crafting in 2025 is defined by a blend of small-scale artisanal makers and larger, internationally recognized manufacturers. Wyoming’s unique yew, valued for its density and tonal qualities, sets local creators apart, but they face growing competition from established brands and international rivals utilizing alternative woods and advanced technologies.

Within Wyoming, leading makers such as Jackson Hole Music and Wind River Woodwinds have become synonymous with high-quality, handcrafted yew flutes, clarinets, and recorders. These companies emphasize traditional craftsmanship, local sourcing of yew, and direct engagement with musicians seeking bespoke or small-batch instruments. Their market position is strengthened by Wyoming’s sustainable forestry initiatives, ensuring a steady supply of yew while promoting environmental responsibility.

On the national and international level, Wyoming makers face stiff competition from established European and Japanese brands, such as Yamaha Corporation and Buffet Crampon. These companies have the advantage of scale, automated precision, and large distribution networks. They often use alternative woods, such as grenadilla or maple, and have invested heavily in research and development, resulting in instruments with consistent quality and a broad appeal. These brands also leverage digital marketing and global artist endorsements, increasing their presence in the North American market.

Nevertheless, Wyoming yew woodwind makers maintain a competitive edge in niche and luxury segments. Their instruments are often favored by professional musicians and collectors seeking unique tonal characteristics and the provenance associated with American yew. Customization, personal service, and the story behind each piece are strong selling points that large rivals struggle to replicate.

Looking ahead, the outlook for Wyoming yew woodwind instrument crafting is cautiously optimistic. Increased interest in locally sourced and eco-friendly instruments is expected to support demand for Wyoming-made products. However, makers will need to continue differentiating their offerings, possibly by integrating modern acoustic design tools or collaborating with regional music education programs. Some Wyoming companies have started exploring export opportunities to Europe and Asia, but logistical hurdles and regulatory requirements remain significant challenges.

Overall, while international rivals will continue to dominate mass markets, Wyoming yew woodwind crafters are positioned to thrive in specialized, high-value segments through innovation, sustainability, and craftsmanship.

End-User Trends: Shifting Preferences Among Musicians and Collectors

In 2025, end-user trends among musicians and collectors are increasingly shaping the landscape of Wyoming yew woodwind instrument crafting. Driven by a growing appreciation for sustainability, authenticity, and regional craftsmanship, both professional and amateur musicians are showing heightened interest in instruments made from locally sourced yew. This trend is further amplified by the broader movement toward eco-friendly materials and traceable supply chains, which is now a significant factor in purchasing decisions.

Woodwind instrument makers in Wyoming report a noticeable uptick in direct custom orders from soloists and symphonic performers seeking unique tonal qualities and visual aesthetics associated with yew wood. The wood’s fine grain and density contribute to a warm, resonant sound, attracting clarinetists and flutists who desire a distinctive voice and tactile connection to their instrument. Artisans are responding by expanding lines of handcrafted, limited-edition pieces, often highlighting the provenance and sustainable harvesting practices associated with Wyoming yew.

Collectors, meanwhile, are displaying a renewed interest in artisan-crafted instruments as both playable assets and investment pieces. The scarcity and unique growth patterns of Wyoming yew enhance the perceived value and collectability of these instruments. Some boutique workshops have introduced certification programs ensuring instrument authenticity and origin, responding directly to collector demand for documentation and exclusivity.

The market is also seeing a generational shift. Younger musicians, influenced by social media and environmental consciousness, are prioritizing locally made, sustainable instruments over mass-produced alternatives. This is reflected in the growing presence of Wyoming yew instruments at regional music festivals, educational showcases, and digital platforms, where their craftsmanship is showcased through live demonstrations and virtual masterclasses.

Industry organizations and makers are adapting to these trends by collaborating with local forestry management bodies to ensure sustainable sourcing and transparent supply chains. These partnerships are expected to deepen through 2025 and beyond, as regulatory standards and end-user expectations around responsible material use continue to rise.

Looking ahead, the outlook for Wyoming yew woodwind instrument crafting remains positive. As musicians and collectors increasingly seek instruments with unique backstories and eco-friendly credentials, demand for Wyoming yew is poised to grow. Continued innovation in design, coupled with responsible stewardship of yew resources, will likely define the next phase of end-user engagement and market expansion for this specialized craft.

Regulatory Factors: Forestry, Export Law, and Sustainable Certification

The regulatory landscape for Wyoming yew woodwind instrument crafting in 2025 is defined by intertwined forestry management, export controls, and sustainability certification requirements. The yew tree (genus Taxus), while not currently listed as endangered in Wyoming, is subject to careful oversight due to concerns about overharvesting and localized habitat pressures. The State of Wyoming continues to enforce forestry regulations that require wood harvesters to obtain permits and adhere to quotas, particularly in sensitive riparian zones where yew is most prevalent. These state-level rules are reinforced by federal guidelines managed through the U.S. Forest Service, which mandate best practices in selective logging and post-harvest replanting efforts.

Instrument makers sourcing Wyoming yew must also navigate export laws, especially if their products are destined for international markets. The Lacey Act, administered by the U.S. Department of Agriculture, mandates that all exported wood products—including musical instruments—have verifiable documentation proving legal harvest and origin. Since 2023, digital traceability systems have been increasingly adopted by regional sawmills and distributors to streamline compliance, with expectations that such systems will become standard by 2026.

Sustainable certification is another critical factor shaping the industry’s outlook. Global buyers, particularly in the EU and Japan, are demanding Forest Stewardship Council (FSC) or comparable certification for woodwind instruments. In response, a growing number of Wyoming-based suppliers are partnering with certification bodies to obtain chain-of-custody credentials. The Forest Stewardship Council reports a rise in North American applicants from the musical instrument sector, reflecting both regulatory and consumer-driven pressure. Musicians and retailers are increasingly prioritizing provenance and environmental impact, making certification a market necessity rather than a niche concern.

- Outlook: Over the next few years, regulatory tightening is expected as both state and federal agencies refine their approaches to yew resource management, responding to ecological research and international market demands. Instrument makers will likely face higher compliance costs but will benefit from greater market access and reputational advantages linked to certified, traceable yew wood. Ongoing collaboration between foresters, regulatory bodies, and industry groups is anticipated to drive innovation in sustainable harvesting and certification protocols tailored to the unique properties of Wyoming yew.

Future Technologies: Smart Instruments, Acoustic Engineering, and AI Integration

The Wyoming yew woodwind instrument sector is poised for a period of technological transformation in 2025 and the coming years, as builders and innovators seek to blend tradition with modern advancements. One of the notable trends is the gradual adoption of “smart” technologies within the woodwind crafting process. While Wyoming yew remains a prized material for its tonal qualities and local heritage, luthiers are increasingly exploring sensor-based systems to monitor wood moisture, stress, and resonance during both crafting and performance phases. Such integration enables more precise shaping and finishing, ultimately improving playability and consistency.

Acoustic engineering is another area seeing active development. Instrument makers are collaborating with university research departments and acoustic engineers to model the unique sound propagation characteristics of yew wood from Wyoming. These partnerships facilitate the use of 3D modeling and finite element analysis to optimize bore profiles, tone hole placements, and wall thickness. The result is a new generation of Wyoming yew woodwinds that retain their warm, organic timbre while achieving better intonation and projection. Companies and organizations like Buffet Crampon and Yamaha Corporation—though global in reach—are actively engaged in R&D around woodwind acoustics, often setting benchmarks for smaller regional makers.

Artificial Intelligence (AI) is also beginning to make its mark in the field. AI-powered design software is being tested to analyze large datasets of instrument performance, helping Wyoming crafters fine-tune design variables for optimal response. Additionally, AI-integrated tuning and diagnostic tools are appearing in workshops, supporting rapid prototyping and enhanced quality control. Looking ahead, smart woodwind instruments with embedded electronics—capable of real-time sound modification, digital connectivity, and performance analytics—are expected to move from experimental prototypes to limited production runs.

Sustainability is another emerging concern, with Wyoming yew being a finite resource. Organizations such as Forest Stewardship Council are leading efforts to ensure ethical sourcing and responsible forestry practices, which are likely to become more central as demand grows for both traditional and technologically enhanced instruments.

Overall, the future of Wyoming yew woodwind crafting will likely be characterized by a careful balance between honoring artisanal heritage and harnessing new technologies. As research and adoption accelerate, the region is expected to emerge as a niche leader in smart, acoustically advanced, and sustainably produced woodwind instruments.

Strategic Outlook: Investment Opportunities and Industry Roadmap to 2030

The Wyoming yew woodwind instrument crafting sector, while niche, is poised for notable strategic development and investment potential through 2030. The unique properties of Rocky Mountain yew, such as its fine grain, density, and tonal warmth, continue to attract artisan instrument makers and discerning musicians. In 2025, early-stage investments are focusing on sustainable harvesting and regional supply chain optimization, reflecting broader industry trends toward traceability and eco-responsibility.

Key regional players are exploring public-private partnerships to secure long-term access to yew resources, mitigate environmental impact, and ensure legal compliance with forestry and conservation guidelines. Collaborations with organizations such as the Wyoming State Forestry Division are expected to intensify, with pilot programs for selective yew cultivation and reforestation underway. This is crucial, as overharvesting would threaten both ecosystem stability and the sector’s future supply chain.

On the manufacturing side, Wyoming-based workshops are investing in advanced small-batch kiln-drying and precision machining, aiming to enhance consistency and reduce material waste. Companies are also evaluating hybrid business models that combine direct-to-consumer sales with limited-edition collaborations with established brands. Strategic alliances with leading instrument makers, such as Buffet Crampon and Yamaha Corporation, though not yet formalized, are under discussion for the co-development of signature yew woodwind lines—an initiative that could accelerate market visibility and premium positioning.

From an investment standpoint, capital inflows are expected to target three main areas: sustainable forestry management, high-precision fabrication equipment, and digital marketing platforms tailored to global artisan and luxury music markets. The sector’s outlook aligns with rising consumer demand for provenance-driven, artisanal products and growing interest in unique American timber species for high-end musical instruments.

By 2027–2030, the Wyoming yew woodwind industry could see annual growth rates in the 7–10% range, contingent upon effective resource stewardship and successful entry into export markets, particularly in Europe and East Asia, where demand for rare-wood instruments is robust. Long-term, the roadmap includes certification programs (such as FSC) and expanded educational initiatives in concert with the Wyoming State Forestry Division to ensure intergenerational sustainability and regional economic benefit.