Biomimetic Filtration Membrane Fabrication in 2025: Pioneering Nature-Inspired Solutions for Next-Gen Water Purification and Industrial Separation. Explore the Breakthroughs, Market Trajectory, and Future Impact of This Transformative Technology.

- Executive Summary: Key Trends and Market Drivers in 2025

- Biomimetic Filtration Membrane Fundamentals: Principles and Materials

- Current State of Fabrication Technologies and Leading Innovators

- Market Size, Segmentation, and 2025–2029 Growth Forecasts

- Emerging Applications: Water Treatment, Bioprocessing, and Beyond

- Competitive Landscape: Major Players and Strategic Partnerships

- Regulatory Environment and Industry Standards

- Challenges in Scalability, Cost, and Performance Optimization

- Recent Breakthroughs and Patent Activity (2023–2025)

- Future Outlook: Disruptive Potential and Long-Term Opportunities

- Sources & References

Executive Summary: Key Trends and Market Drivers in 2025

Biomimetic filtration membrane fabrication is poised for significant advancement in 2025, driven by the convergence of material science innovation, sustainability imperatives, and the urgent need for efficient water and process filtration solutions. The sector is witnessing a shift from conventional polymeric and ceramic membranes toward next-generation membranes inspired by biological systems, such as aquaporins and other protein channels, which offer superior selectivity and permeability.

A key trend in 2025 is the scaling up of biomimetic membrane production, with several industry leaders and technology developers moving from pilot to commercial-scale manufacturing. Aquaporin A/S, a Danish company, remains at the forefront, leveraging its proprietary aquaporin-based technology to produce membranes for water purification and industrial applications. Their focus on integrating natural water channel proteins into robust membrane matrices has set benchmarks for both performance and sustainability. Similarly, Evonik Industries AG is investing in advanced membrane materials, including those that mimic biological transport mechanisms, to address challenges in water treatment and specialty separations.

Sustainability is a central market driver, as industries and municipalities seek to reduce energy consumption and chemical usage in filtration processes. Biomimetic membranes, with their high flux and low fouling characteristics, are increasingly recognized for their potential to lower operational costs and environmental impact. The European Union’s Green Deal and similar regulatory frameworks in Asia and North America are accelerating adoption, with funding and incentives for innovative water technologies.

Another notable trend is the integration of biomimetic membranes into modular and decentralized water treatment systems. Companies such as Toray Industries, Inc. and SUEZ are exploring hybrid systems that combine biomimetic elements with established membrane technologies, aiming to enhance performance in challenging feedwaters and reduce maintenance requirements.

Looking ahead, the outlook for biomimetic filtration membrane fabrication is robust. Ongoing research into scalable protein synthesis, membrane stability, and antifouling coatings is expected to yield commercially viable products for broader markets, including pharmaceuticals, food and beverage, and industrial wastewater. Strategic partnerships between technology developers, material suppliers, and end-users are anticipated to accelerate commercialization and standardization efforts. As a result, biomimetic membranes are set to play a pivotal role in the global transition toward sustainable and resilient water management systems in the coming years.

Biomimetic Filtration Membrane Fundamentals: Principles and Materials

Biomimetic filtration membrane fabrication is a rapidly advancing field, leveraging nature-inspired designs to achieve superior selectivity, permeability, and fouling resistance compared to conventional membranes. The core principle involves mimicking biological structures—such as aquaporins, ion channels, or cellular lipid bilayers—to create membranes that can efficiently separate water from contaminants or selectively filter specific molecules. In 2025, the focus remains on scalable manufacturing, material robustness, and integration into existing water treatment and industrial separation systems.

A key material in biomimetic membrane fabrication is the incorporation of aquaporin proteins, which are highly efficient water channels found in cell membranes. Companies like Aquaporin A/S have pioneered the commercial production of aquaporin-based membranes, utilizing proprietary techniques to embed these proteins into stable polymeric supports. Their technology enables high water flux and low energy consumption, and in 2025, they continue to expand production capacity and application scope, including municipal, industrial, and point-of-use water purification.

Another significant approach involves the use of block copolymers and self-assembling amphiphilic molecules to mimic the structure and function of biological membranes. Evonik Industries and BASF are among the chemical manufacturers developing advanced polymers and nanomaterials tailored for membrane fabrication. These materials offer tunable pore sizes and enhanced chemical stability, addressing challenges of scalability and durability that have historically limited biomimetic membranes’ commercial adoption.

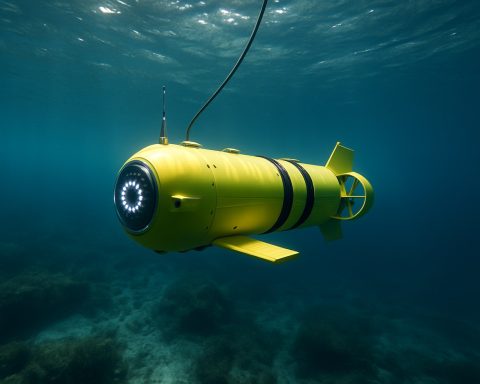

Nanotechnology also plays a crucial role, with the integration of carbon nanotubes, graphene oxide, and other nanomaterials to replicate the selective transport properties of biological channels. SUEZ and Toray Industries are actively developing and piloting nanocomposite membranes, aiming for improved anti-fouling properties and higher throughput in desalination and wastewater treatment applications.

Looking ahead, the outlook for biomimetic membrane fabrication in the next few years is promising. Industry collaborations and public-private partnerships are accelerating the transition from laboratory-scale prototypes to full-scale manufacturing. The sector is expected to benefit from advances in synthetic biology, allowing for more efficient and cost-effective production of membrane proteins and functionalized polymers. As regulatory standards for water quality and sustainability tighten globally, biomimetic membranes are positioned to play a pivotal role in next-generation filtration systems, with ongoing investments from major industry players and increasing adoption in both developed and emerging markets.

Current State of Fabrication Technologies and Leading Innovators

Biomimetic filtration membrane fabrication has rapidly advanced in recent years, with 2025 marking a period of significant transition from laboratory-scale innovation to early-stage commercialization. The field draws inspiration from natural filtration systems—such as aquaporins in biological membranes—to achieve high selectivity, permeability, and fouling resistance. The current state of fabrication technologies is characterized by a convergence of materials science, nanotechnology, and precision engineering, enabling the scalable production of membranes with tailored properties.

A central focus in 2025 is the integration of aquaporin proteins and artificial water channels into polymeric and ceramic supports. Companies like Aquaporin A/S have pioneered the commercial deployment of biomimetic membranes, leveraging proprietary techniques to embed natural aquaporins into robust membrane matrices. Their products are now being used in both industrial and consumer water purification systems, demonstrating the viability of biomimetic approaches at scale. Aquaporin A/S continues to expand its manufacturing capabilities, with new facilities and partnerships aimed at increasing output and reducing costs.

Another notable innovator is Evonik Industries AG, which has invested in the development of synthetic polymer membranes that mimic biological channels. Their research focuses on the use of block copolymers and advanced nanofabrication techniques to create highly selective filtration layers. These efforts are supported by collaborations with academic institutions and industry partners, aiming to accelerate the transition from pilot-scale to full-scale production.

In Asia, Toray Industries, Inc. and Asahi Kasei Corporation are leveraging their expertise in membrane technology to explore biomimetic enhancements. Both companies have announced R&D initiatives targeting the incorporation of bioinspired structures into their next-generation reverse osmosis and nanofiltration products. These initiatives are expected to yield commercial products within the next few years, particularly for applications in desalination and industrial wastewater treatment.

The fabrication landscape is also shaped by advances in 3D printing and layer-by-layer assembly, which allow for precise control over membrane architecture. Startups and established players alike are experimenting with these methods to optimize pore size distribution and surface chemistry, further improving performance and durability.

Looking ahead, the outlook for biomimetic filtration membrane fabrication is promising. As manufacturing processes mature and costs decline, broader adoption across water treatment, pharmaceutical, and food industries is anticipated. Ongoing investment by leading companies and the emergence of new entrants suggest that biomimetic membranes will play an increasingly important role in addressing global filtration challenges through 2025 and beyond.

Market Size, Segmentation, and 2025–2029 Growth Forecasts

The global market for biomimetic filtration membrane fabrication is poised for significant expansion between 2025 and 2029, driven by escalating demand for advanced water treatment, industrial separation, and biomedical applications. Biomimetic membranes, inspired by natural structures such as aquaporins and ion channels, offer superior selectivity, permeability, and fouling resistance compared to conventional polymeric membranes. This technological edge is catalyzing adoption across municipal water utilities, pharmaceutical manufacturing, food and beverage processing, and emerging sectors like hydrogen production.

In 2025, the biomimetic membrane market is estimated to reach a value in the low hundreds of millions USD, with projections indicating a compound annual growth rate (CAGR) exceeding 15% through 2029. The Asia-Pacific region is expected to lead in both production and consumption, propelled by large-scale investments in water infrastructure and industrial modernization, particularly in China, Japan, and South Korea. Europe and North America are also key markets, with strong emphasis on sustainable water management and regulatory support for innovative filtration technologies.

Market segmentation reveals three primary application domains:

- Water and Wastewater Treatment: Municipal and industrial water treatment remains the largest segment, with biomimetic membranes being deployed for desalination, ultrapure water production, and contaminant removal. Companies such as Aquaporin A/S are commercializing aquaporin-based membranes, which mimic natural water channels to achieve high flux and selectivity.

- Industrial Separation: Sectors including pharmaceuticals, food and beverage, and chemicals are adopting biomimetic membranes for selective separation of molecules, protein purification, and solvent recovery. Evonik Industries AG is actively developing and scaling up membrane technologies for industrial clients.

- Biomedical and Life Sciences: The use of biomimetic membranes in hemodialysis, drug delivery, and biosensing is a fast-growing niche, with research collaborations and pilot projects underway in Europe and Asia.

Key players in the biomimetic membrane sector include Aquaporin A/S (Denmark), a pioneer in aquaporin-based water filtration; Evonik Industries AG (Germany), which is investing in next-generation membrane materials; and Toray Industries, Inc. (Japan), a global leader in advanced membrane manufacturing. These companies are expanding production capacity and forming strategic partnerships to accelerate commercialization.

Looking ahead to 2029, the market outlook is robust, with biomimetic membrane fabrication expected to benefit from ongoing R&D, cost reductions through scale, and increasing regulatory and consumer focus on sustainable, high-performance filtration solutions. The convergence of material science, nanotechnology, and bioengineering is anticipated to yield further breakthroughs, solidifying biomimetic membranes as a cornerstone of next-generation filtration technologies.

Emerging Applications: Water Treatment, Bioprocessing, and Beyond

Biomimetic filtration membrane fabrication is rapidly advancing, with 2025 poised to be a pivotal year for the deployment of these technologies in water treatment, bioprocessing, and other sectors. Biomimetic membranes, inspired by natural structures such as aquaporins and ion channels, offer superior selectivity, permeability, and fouling resistance compared to conventional polymeric membranes. The integration of biological or bioinspired components into synthetic matrices is enabling new levels of performance, particularly in challenging separation environments.

In water treatment, biomimetic membranes are being scaled up for both desalination and wastewater reuse. Companies like Aquaporin A/S have commercialized membranes incorporating aquaporin proteins, which mimic the highly selective water transport found in living cells. Their products are being adopted in industrial and municipal water purification systems, with ongoing pilot projects in Asia and Europe. Similarly, ZwitterCo is leveraging zwitterionic chemistries to create fouling-resistant membranes for treating complex wastewaters, including those from food and beverage and bioprocessing industries.

Bioprocessing is another area where biomimetic membranes are gaining traction. The pharmaceutical and biotechnology sectors require highly selective separations for protein purification, virus removal, and cell harvesting. Companies such as Merck KGaA (operating as MilliporeSigma in the US and Canada) are investing in next-generation filtration platforms that incorporate bioinspired surface chemistries and structures to enhance throughput and product purity. These innovations are expected to support the growing demand for biologics and cell-based therapies, with several new membrane products anticipated to launch by 2026.

Beyond water and bioprocessing, biomimetic membranes are being explored for applications in gas separation, energy storage, and even medical devices. For example, Evonik Industries AG is developing membranes with tailored pore architectures for selective gas separations, targeting hydrogen purification and carbon capture. The company’s expertise in advanced polymers and membrane engineering positions it as a key player in the transition to sustainable energy systems.

Looking ahead, the outlook for biomimetic filtration membrane fabrication is robust. Industry collaborations, government funding, and advances in materials science are accelerating the commercialization of these technologies. As manufacturing processes mature and costs decrease, biomimetic membranes are expected to capture a growing share of the filtration market, offering sustainable solutions for water scarcity, clean energy, and high-value bioproducts.

Competitive Landscape: Major Players and Strategic Partnerships

The competitive landscape for biomimetic filtration membrane fabrication in 2025 is characterized by a dynamic mix of established filtration technology leaders, innovative startups, and strategic collaborations between academia and industry. The sector is witnessing accelerated commercialization efforts, with companies leveraging biomimicry to enhance membrane selectivity, permeability, and fouling resistance—key performance metrics for water treatment, desalination, and industrial separations.

Among the most prominent players, Dow continues to invest in advanced membrane technologies, building on its legacy in reverse osmosis and nanofiltration. The company’s research and development initiatives increasingly incorporate biomimetic principles, such as aquaporin-inspired channels, to improve water flux and energy efficiency. Similarly, Toray Industries—a global leader in membrane materials—has expanded its portfolio to include next-generation membranes that mimic biological structures, aiming to address both municipal and industrial water challenges.

A notable innovator in this space is Aquaporin A/S, a Danish company specializing in membranes that utilize actual aquaporin proteins to achieve high selectivity and low energy consumption. Aquaporin’s technology has moved from pilot to commercial scale, with installations in both drinking water and industrial applications. The company has formed strategic partnerships with water treatment system integrators and OEMs to accelerate market adoption.

In Asia, Hyflux (Singapore) and SUEZ (France, with significant operations in Asia) are actively exploring biomimetic enhancements to their membrane offerings, often in collaboration with research institutes. These partnerships are crucial for translating laboratory-scale innovations into scalable, robust products suitable for diverse water matrices.

The competitive landscape is further shaped by cross-sector alliances. For example, collaborations between membrane manufacturers and biotechnology firms are enabling the integration of synthetic biology and advanced materials science. This is exemplified by joint ventures and licensing agreements aimed at scaling up the production of protein-based or peptide-functionalized membranes.

Looking ahead, the next few years are expected to see intensified competition as more players enter the market and existing companies expand their biomimetic membrane portfolios. Intellectual property strategies, supply chain integration, and the ability to demonstrate long-term operational reliability will be key differentiators. The sector’s trajectory will also be influenced by regulatory drivers and the growing demand for sustainable, energy-efficient water treatment solutions worldwide.

Regulatory Environment and Industry Standards

The regulatory environment for biomimetic filtration membrane fabrication is evolving rapidly in 2025, reflecting both the maturation of the technology and its increasing adoption in water treatment, healthcare, and industrial applications. Regulatory frameworks are being shaped by the need to ensure safety, efficacy, and environmental sustainability, while also fostering innovation in this emerging sector.

In the United States, the U.S. Environmental Protection Agency (EPA) continues to play a central role in setting standards for water filtration technologies, including those utilizing biomimetic membranes. The EPA’s regulatory focus is on ensuring that new membrane materials meet stringent requirements for contaminant removal, durability, and chemical safety. In 2025, the agency is expected to update its guidance for advanced membrane systems, incorporating specific provisions for biomimetic and bioinspired materials, particularly regarding their long-term stability and potential for leaching of novel components.

In Europe, the European Chemicals Agency (ECHA) and the European Medicines Agency (EMA) are key regulatory bodies overseeing the use of biomimetic membranes in both industrial and medical contexts. The ECHA’s REACH regulation is particularly relevant, as it requires comprehensive safety data for any new chemical substances used in membrane fabrication. The EMA, meanwhile, is increasingly involved as biomimetic membranes are explored for medical filtration devices, such as artificial kidneys and blood purification systems.

Industry standards are also being developed and refined by organizations such as the International Organization for Standardization (ISO) and the ASTM International. In 2025, ISO is expected to release updated standards for membrane performance testing, including protocols tailored to the unique properties of biomimetic membranes, such as selective permeability and anti-fouling characteristics. ASTM International is similarly working on new test methods and material specifications to address the growing diversity of biomimetic membrane materials and fabrication techniques.

Major industry players, including Dow and Toray Industries, are actively participating in standardization efforts and regulatory consultations. Both companies are recognized for their advanced membrane technologies and are investing in biomimetic approaches to enhance selectivity and energy efficiency. Their involvement is helping to shape practical, globally harmonized standards that can accelerate commercialization while ensuring public and environmental safety.

Looking ahead, the regulatory landscape for biomimetic filtration membranes is expected to become more defined and supportive, with increased collaboration between regulators, industry, and research institutions. This will likely facilitate broader adoption of biomimetic membranes across sectors, provided that manufacturers continue to demonstrate compliance with evolving safety and performance standards.

Challenges in Scalability, Cost, and Performance Optimization

Biomimetic filtration membrane fabrication, inspired by natural structures such as aquaporins and cell membranes, is advancing rapidly, but significant challenges remain in scaling up production, reducing costs, and optimizing performance for industrial adoption. As of 2025, the transition from laboratory-scale prototypes to commercially viable products is hindered by several interrelated factors.

One of the primary challenges is the scalability of membrane fabrication processes. Biomimetic membranes often rely on delicate biological or bioinspired components, such as aquaporin proteins or synthetic analogs, which require precise integration into robust polymer matrices. The production of these proteins at industrial scale remains complex and expensive, with yields and stability still lagging behind conventional membrane materials. Companies like Aquaporin A/S have pioneered the use of aquaporin-embedded membranes, but their manufacturing processes involve specialized biotechnological steps that are not yet as streamlined or cost-effective as traditional polymeric membrane fabrication.

Cost is another significant barrier. The incorporation of functional biomolecules, the need for high-purity feedstocks, and the multi-step assembly processes all contribute to higher production costs compared to standard reverse osmosis or ultrafiltration membranes. While some manufacturers are exploring recombinant protein production and scalable membrane casting techniques, the price per square meter of biomimetic membranes remains substantially higher. For instance, Aquaporin A/S and Evonik Industries AG are both investing in process optimization and automation to reduce costs, but widespread adoption in municipal or industrial water treatment is still limited by economic considerations.

Performance optimization is also a critical focus. Biomimetic membranes promise superior selectivity and permeability, but maintaining these properties under real-world operating conditions—such as high pressures, variable feedwater quality, and long-term fouling—remains a technical hurdle. Ensuring the stability and functionality of embedded proteins or channels over extended periods is a key research area. Industry players like Evonik Industries AG are collaborating with academic and industrial partners to develop more robust membrane architectures and antifouling surface modifications.

Looking ahead, the outlook for biomimetic membrane technology is cautiously optimistic. Ongoing investments in biomanufacturing, materials science, and process engineering are expected to yield incremental improvements in scalability and cost-effectiveness over the next few years. Strategic partnerships between membrane manufacturers, biotechnology firms, and end-users will be crucial for accelerating commercialization and addressing the remaining technical and economic barriers.

Recent Breakthroughs and Patent Activity (2023–2025)

Between 2023 and 2025, the field of biomimetic filtration membrane fabrication has witnessed significant breakthroughs, with a marked increase in patent filings and commercial interest. Biomimetic membranes, inspired by natural structures such as aquaporins and cell membranes, are being engineered to achieve superior selectivity, permeability, and fouling resistance compared to conventional polymeric membranes.

A notable trend is the translation of laboratory-scale innovations into scalable manufacturing processes. For instance, several companies have reported advances in embedding aquaporin proteins into robust polymer matrices, enabling the production of membranes with high water flux and salt rejection. Aquaporin A/S, a Danish pioneer in this space, has expanded its patent portfolio with new filings covering methods for stabilizing protein channels during membrane fabrication and integrating them into spiral-wound modules for industrial water treatment. Their recent patents also address improved longevity and resistance to chemical degradation, which are critical for real-world deployment.

In parallel, Asian manufacturers have accelerated the commercialization of biomimetic membranes. Toray Industries, Inc., a global leader in advanced materials, has announced pilot-scale production of next-generation reverse osmosis (RO) membranes incorporating biomimetic elements. Their patent activity in 2024–2025 includes novel surface modification techniques that mimic the antifouling properties of fish skin, reducing biofilm formation and extending membrane life. Similarly, LG Chem has disclosed patents on hybrid membranes that combine synthetic polymers with peptide-based channels, targeting both desalination and industrial wastewater reuse.

Patent databases indicate a surge in filings related to scalable fabrication methods, such as layer-by-layer assembly and interfacial polymerization, which are essential for integrating delicate biomolecules into durable membrane structures. Industry bodies like the Membrane Technology Forum have highlighted these developments in recent conferences, noting a shift from proof-of-concept studies to pilot and demonstration projects.

Looking ahead, the outlook for 2025 and beyond is promising. The convergence of synthetic biology, nanofabrication, and advanced materials science is expected to yield membranes with unprecedented performance. Companies are increasingly collaborating with academic institutions to accelerate the translation of biomimetic concepts into commercial products. As regulatory frameworks evolve and water scarcity intensifies, the adoption of biomimetic filtration membranes is poised to expand across municipal, industrial, and even pharmaceutical sectors.

Future Outlook: Disruptive Potential and Long-Term Opportunities

The future outlook for biomimetic filtration membrane fabrication is marked by significant disruptive potential and a broad spectrum of long-term opportunities, particularly as global industries seek sustainable, high-performance solutions for water treatment, healthcare, and industrial separations. As of 2025, the convergence of advanced materials science, nanotechnology, and bioinspired engineering is accelerating the commercialization of membranes that mimic natural filtration processes, such as those found in biological cell membranes and fish gills.

Key industry players are scaling up production and refining fabrication techniques to address challenges of scalability, durability, and cost-effectiveness. For instance, Evonik Industries is actively developing polymer-based membranes with enhanced selectivity and fouling resistance, leveraging their expertise in specialty chemicals and high-performance polymers. Similarly, Dow is investing in next-generation reverse osmosis and nanofiltration membranes, incorporating biomimetic design principles to improve water permeability and energy efficiency.

A notable trend is the integration of aquaporin proteins—nature’s highly selective water channels—into synthetic membranes. Aquaporin A/S, a Danish company, is at the forefront of this technology, commercializing membranes that utilize aquaporin proteins for applications ranging from industrial water recycling to point-of-use drinking water systems. Their products demonstrate the feasibility of large-scale biomimetic membrane deployment, with ongoing partnerships to expand into new markets.

Looking ahead, the sector is poised for further breakthroughs as fabrication methods such as layer-by-layer assembly, 3D printing, and advanced surface modification become more accessible and cost-competitive. The adoption of green manufacturing processes and biodegradable materials is also expected to gain momentum, aligning with global sustainability goals and regulatory pressures.

Long-term opportunities extend beyond water treatment. Biomimetic membranes are being explored for gas separation, medical devices (such as artificial kidneys), and even energy generation via osmotic power. Industry consortia and public-private partnerships are likely to play a pivotal role in overcoming technical and regulatory hurdles, fostering innovation ecosystems that accelerate market adoption.

In summary, the disruptive potential of biomimetic filtration membrane fabrication lies in its ability to deliver superior performance while addressing pressing environmental and resource challenges. As leading companies continue to invest in R&D and scale-up, the next few years are expected to witness a transition from niche applications to mainstream adoption across multiple sectors.

Sources & References

- Aquaporin A/S

- Evonik Industries AG

- SUEZ

- Aquaporin A/S

- BASF

- ZwitterCo

- European Chemicals Agency

- European Medicines Agency

- International Organization for Standardization

- ASTM International