Fiber Bragg-Based Biosensing Technologies in 2025: Transforming Diagnostics and Monitoring with Precision Photonics. Explore Market Growth, Innovations, and Strategic Opportunities Shaping the Next Five Years.

- Executive Summary: Key Trends and Market Drivers

- Technology Overview: Fundamentals of Fiber Bragg-Based Biosensing

- Current Market Landscape and Leading Players

- Innovations in Sensor Design and Integration

- Applications in Healthcare, Environmental, and Industrial Sectors

- Regulatory Environment and Industry Standards

- Market Size, Segmentation, and 2025–2030 Growth Forecasts

- Competitive Analysis: Company Strategies and Partnerships

- Challenges, Risks, and Barriers to Adoption

- Future Outlook: Emerging Opportunities and Strategic Recommendations

- Sources & References

Executive Summary: Key Trends and Market Drivers

Fiber Bragg-based biosensing technologies are poised for significant growth and innovation in 2025 and the coming years, driven by advances in photonic engineering, increasing demand for real-time and label-free biosensing, and expanding applications in healthcare, environmental monitoring, and industrial process control. Fiber Bragg Gratings (FBGs), which are periodic variations in the refractive index inscribed along optical fibers, have emerged as a robust platform for biosensing due to their high sensitivity, multiplexing capability, and immunity to electromagnetic interference.

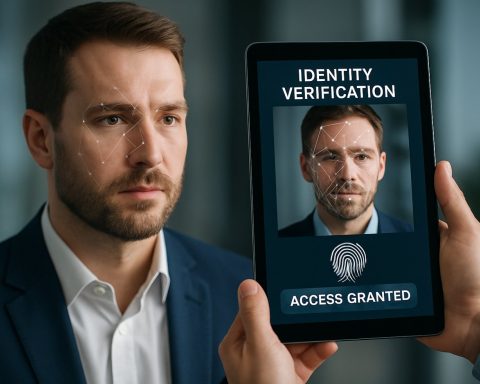

A key trend in 2025 is the integration of FBG biosensors into point-of-care diagnostics and wearable health monitoring devices. Companies such as Hottinger Brüel & Kjær (HBK), a leader in fiber optic sensing, are actively developing FBG-based solutions for medical diagnostics, leveraging the technology’s ability to detect minute changes in biological parameters such as temperature, strain, and biochemical interactions. The miniaturization of FBG sensors and advances in biocompatible coatings are enabling their deployment in minimally invasive and implantable devices, addressing the growing need for continuous patient monitoring.

Another driver is the adoption of FBG biosensors in environmental and food safety monitoring. Organizations like The Optical Society (Optica) highlight the use of FBGs for detecting contaminants, pathogens, and toxins in water and food supplies, capitalizing on their rapid response and multiplexing capabilities. The ability to functionalize FBG surfaces with selective biorecognition elements is expanding the range of detectable analytes, making these sensors attractive for regulatory compliance and public health initiatives.

Industrial sectors are also embracing FBG biosensing for process control and safety. Companies such as Luna Innovations are advancing FBG sensor networks for real-time monitoring of bioprocesses, chemical production, and structural health, where early detection of biological or chemical changes can prevent costly downtime and ensure product quality.

Looking ahead, the market outlook for fiber Bragg-based biosensing technologies is robust, with ongoing research focused on enhancing sensitivity, selectivity, and integration with digital platforms for data analytics and remote monitoring. The convergence of photonics, biotechnology, and IoT is expected to accelerate commercialization and adoption across diverse sectors. As regulatory frameworks evolve and end-user awareness increases, FBG biosensors are set to play a pivotal role in the next generation of smart, connected biosensing solutions.

Technology Overview: Fundamentals of Fiber Bragg-Based Biosensing

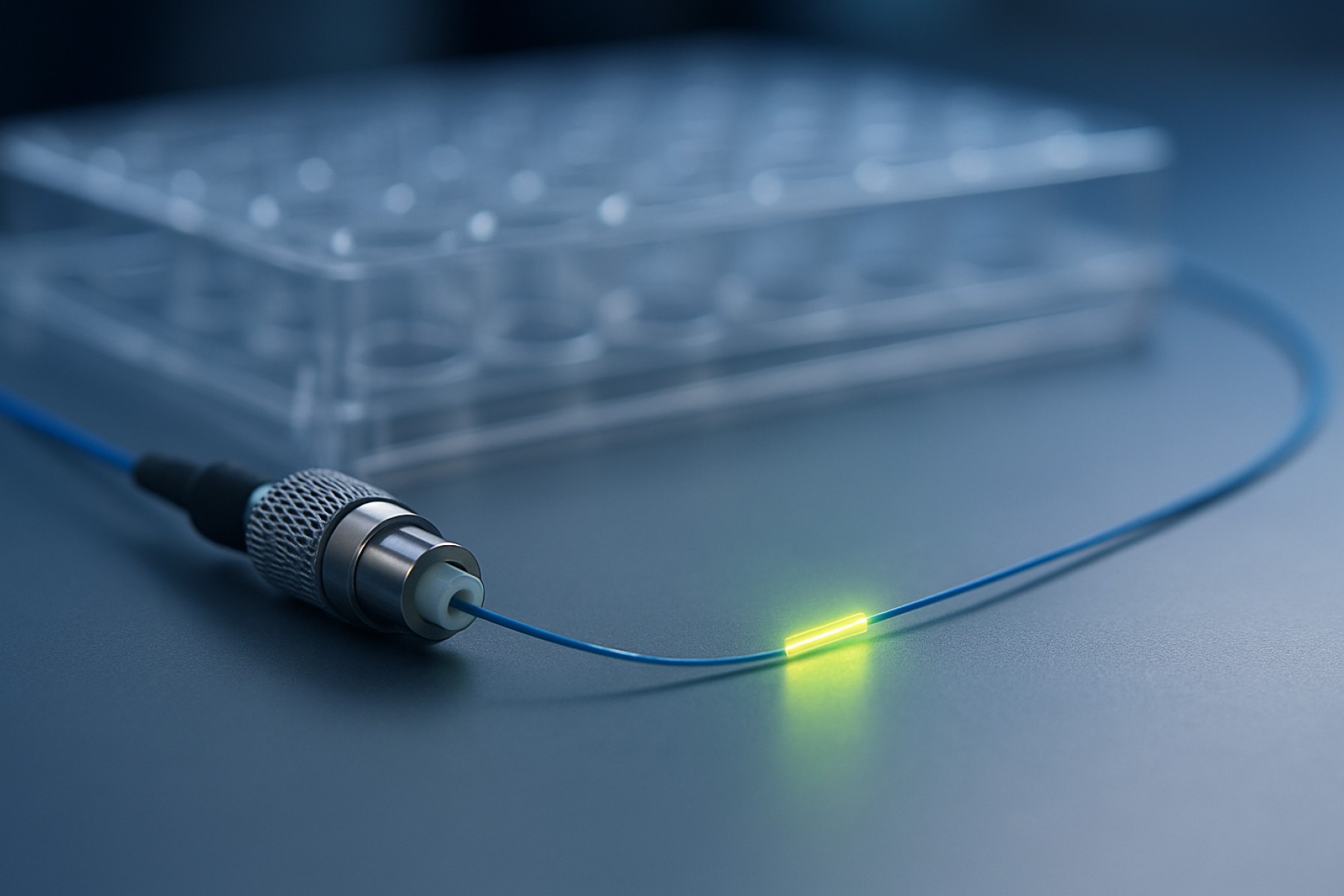

Fiber Bragg-based biosensing technologies leverage the unique properties of Fiber Bragg Gratings (FBGs) to enable highly sensitive, real-time detection of biological and chemical analytes. At their core, FBGs are periodic variations of the refractive index inscribed along the core of an optical fiber, which reflect specific wavelengths of light while transmitting others. When exposed to external stimuli—such as changes in temperature, strain, or the presence of target biomolecules—the reflected wavelength (Bragg wavelength) shifts, providing a direct, quantifiable signal.

In biosensing applications, FBGs are typically functionalized with biorecognition elements (e.g., antibodies, aptamers, or enzymes) that selectively bind to target analytes. This binding event induces a local refractive index change or mechanical strain, which is transduced into a measurable shift in the Bragg wavelength. The label-free, multiplexed, and real-time nature of FBG-based sensors makes them attractive for medical diagnostics, environmental monitoring, and food safety.

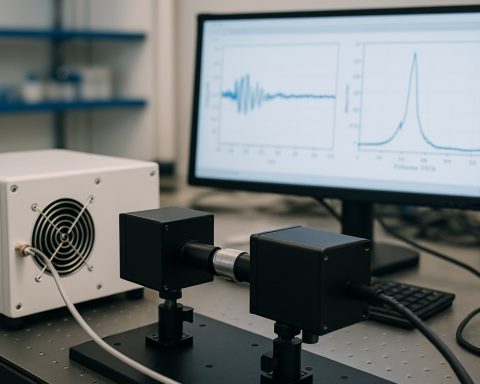

As of 2025, the field is witnessing rapid advancements in both the fabrication and functionalization of FBGs. Companies such as FBGS Technologies and Luna Innovations are at the forefront of developing high-quality FBGs and interrogation systems. FBGS Technologies specializes in draw-tower and femtosecond laser-based FBG inscription, enabling high-density multiplexing and robust sensor arrays. Luna Innovations provides advanced optical sensing platforms that integrate FBGs for diverse applications, including biomedical sensing.

Recent years have seen the integration of FBGs with microfluidic platforms and advanced surface chemistries, enhancing sensitivity and specificity. For example, the use of nanostructured coatings and molecularly imprinted polymers is enabling detection limits in the picomolar range for biomarkers and pathogens. The miniaturization and ruggedization of FBG interrogation units, as developed by Micron Optics (now part of Luna Innovations), are facilitating deployment in point-of-care and field settings.

Looking ahead, the next few years are expected to bring further improvements in multiplexing capabilities, allowing simultaneous detection of multiple analytes on a single fiber. The convergence of FBG technology with artificial intelligence and cloud-based data analytics is anticipated to accelerate the adoption of fiber Bragg-based biosensors in clinical diagnostics and environmental surveillance. Industry collaborations and standardization efforts, led by organizations such as the IEEE and Optica (formerly OSA), are likely to play a pivotal role in shaping the future landscape of FBG biosensing technologies.

Current Market Landscape and Leading Players

Fiber Bragg-based biosensing technologies are experiencing significant momentum in 2025, driven by advances in photonic integration, miniaturization, and the growing demand for real-time, label-free biosensing in medical diagnostics, environmental monitoring, and industrial applications. Fiber Bragg Gratings (FBGs), which are periodic variations in the refractive index of optical fibers, have become a cornerstone for highly sensitive, multiplexed biosensors due to their immunity to electromagnetic interference, compactness, and ability to be embedded in various environments.

The current market landscape is shaped by a mix of established photonics companies, specialized sensor manufacturers, and emerging startups. Hottinger Brüel & Kjær (HBK) is a prominent player, leveraging its expertise in optical measurement to offer FBG-based sensing solutions for structural health monitoring and biomedical research. Luna Innovations is another key company, providing advanced fiber optic sensing platforms that include FBG biosensors for applications ranging from medical diagnostics to pharmaceutical process monitoring. Their systems are recognized for high sensitivity and multiplexing capabilities, which are critical for modern biosensing needs.

In Europe, FiberSensing (a part of HBM) continues to expand its portfolio of FBG-based sensors, with a focus on both industrial and biomedical markets. The company is known for its robust, field-deployable solutions and ongoing collaborations with research institutions to push the boundaries of biosensing performance. Meanwhile, Optical Solutions Group (OSG) in Japan is investing in the development of FBG biosensors tailored for point-of-care diagnostics and environmental monitoring, reflecting the global diversification of applications.

Startups and university spin-offs are also contributing to the sector’s dynamism. Companies such as Sensuron are commercializing distributed fiber optic sensing systems that integrate FBG technology for real-time, multi-parameter biosensing. These systems are increasingly being adopted in life sciences and medical device development, where precise, minimally invasive monitoring is essential.

Looking ahead, the market is expected to see further growth as FBG biosensors are integrated with microfluidic platforms and advanced data analytics, enabling rapid, high-throughput detection of biomarkers. The convergence of photonics and biotechnology is likely to yield new products with enhanced specificity and portability, addressing unmet needs in personalized medicine and remote health monitoring. As regulatory pathways for optical biosensors become clearer, established players and agile newcomers alike are poised to accelerate commercialization and adoption across diverse sectors.

Innovations in Sensor Design and Integration

Fiber Bragg grating (FBG)-based biosensing technologies are experiencing significant innovation in sensor design and integration as of 2025, driven by the demand for highly sensitive, multiplexed, and miniaturized biosensors for medical diagnostics, environmental monitoring, and industrial applications. FBG sensors, which operate by reflecting specific wavelengths of light in response to changes in strain or temperature, are being adapted for biochemical detection through advanced surface functionalization and integration with microfluidic systems.

Recent developments focus on enhancing the specificity and sensitivity of FBG biosensors. Companies such as Hottinger Brüel & Kjær and Luna Innovations are at the forefront, offering FBG interrogation systems and sensor arrays that support multiplexed detection—enabling simultaneous monitoring of multiple biomarkers or analytes. These platforms are increasingly being integrated with lab-on-fiber and lab-on-chip technologies, allowing for real-time, in situ analysis with minimal sample volumes.

A key innovation in 2025 is the use of nanostructured coatings and biorecognition elements (such as antibodies, aptamers, or molecularly imprinted polymers) directly on the FBG surface. This approach, adopted by several sensor manufacturers, enhances the selectivity of the sensors for target biomolecules, while maintaining the inherent advantages of FBGs—such as immunity to electromagnetic interference and compatibility with remote sensing. For example, Optical Solutions Group and Fiber Bragg are developing FBG biosensors with advanced surface chemistries tailored for medical diagnostics and environmental biosensing.

Integration with microfluidic platforms is another major trend, enabling automated sample handling and improved sensor response times. Companies like Luna Innovations are collaborating with microfluidics specialists to create compact, portable biosensing devices suitable for point-of-care testing and field deployment. These integrated systems are expected to play a crucial role in personalized medicine, infectious disease detection, and food safety monitoring over the next few years.

Looking ahead, the outlook for FBG-based biosensing technologies is robust. Ongoing research and commercial investment are expected to yield sensors with even greater multiplexing capabilities, lower detection limits, and enhanced robustness for deployment in challenging environments. As standardization efforts progress and manufacturing costs decrease, FBG biosensors are poised to become a mainstay in both clinical and industrial biosensing applications by the late 2020s.

Applications in Healthcare, Environmental, and Industrial Sectors

Fiber Bragg-based biosensing technologies are rapidly advancing, with significant applications emerging across healthcare, environmental monitoring, and industrial sectors in 2025 and the coming years. These sensors, leveraging the unique properties of Fiber Bragg Gratings (FBGs), offer high sensitivity, multiplexing capabilities, and immunity to electromagnetic interference, making them ideal for real-time, distributed sensing in challenging environments.

In healthcare, FBG biosensors are increasingly being integrated into wearable and implantable devices for continuous physiological monitoring. Recent developments focus on minimally invasive sensors for real-time detection of biomarkers such as glucose, lactate, and specific proteins, supporting early diagnosis and personalized medicine. Companies like FBGS Technologies GmbH and Luna Innovations are at the forefront, providing FBG-based solutions for medical device manufacturers and research institutions. These sensors are being trialed in smart catheters, wound monitoring patches, and respiratory monitoring systems, with clinical validation studies underway to meet regulatory requirements for broader adoption.

Environmental monitoring is another area witnessing robust growth. FBG biosensors are deployed for the detection of contaminants, pathogens, and chemical agents in water and air. Their ability to function in harsh and remote locations, combined with multiplexing (monitoring multiple parameters along a single fiber), is driving adoption in water treatment plants and air quality monitoring networks. Organizations such as Hottinger Brüel & Kjær (HBK) and Optical Solutions Group are expanding their portfolios to include FBG-based environmental sensors, supporting government and industrial initiatives for real-time, distributed environmental surveillance.

In industrial sectors, FBG biosensors are being integrated into process control systems for the detection of biological and chemical hazards, as well as for structural health monitoring in food processing, pharmaceuticals, and biomanufacturing. The technology’s robustness and ability to provide distributed sensing over large infrastructures are key advantages. Companies like Microsens SA and Smartec SA are delivering FBG-based solutions tailored for industrial biosensing, including systems for monitoring fermentation processes and detecting microbial contamination in pipelines.

Looking ahead, the outlook for fiber Bragg-based biosensing technologies is strong, with ongoing R&D focused on enhancing sensitivity, miniaturization, and integration with wireless data platforms. The convergence of FBG biosensors with artificial intelligence and IoT is expected to further expand their applications, enabling predictive analytics and automated response systems across healthcare, environmental, and industrial domains.

Regulatory Environment and Industry Standards

The regulatory environment and industry standards for Fiber Bragg-based biosensing technologies are rapidly evolving as these devices transition from research laboratories to clinical and industrial applications. In 2025, the focus is on harmonizing safety, performance, and interoperability requirements to facilitate broader adoption, particularly in healthcare, environmental monitoring, and food safety sectors.

Fiber Bragg grating (FBG) biosensors, which utilize periodic variations in the refractive index of optical fibers to detect biological and chemical changes, are subject to both general photonics standards and emerging biosensor-specific guidelines. The International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established foundational standards for optical fiber components (e.g., ISO/IEC 11801 for cabling and IEC 61757 for fiber optic sensors), which are now being adapted to address the unique requirements of biosensing, such as biocompatibility, sterilization, and sensitivity to biological analytes.

In the United States, the U.S. Food and Drug Administration (FDA) continues to refine its regulatory pathways for novel biosensors, including those based on FBG technology. The FDA’s Center for Devices and Radiological Health (CDRH) is increasingly engaging with manufacturers to clarify premarket submission requirements, emphasizing analytical validation, clinical performance, and cybersecurity for connected devices. The FDA’s Breakthrough Devices Program has also accelerated the review of several FBG-based biosensing platforms, particularly those targeting rapid diagnostics and continuous physiological monitoring.

On the industry side, leading manufacturers such as HBM (Hottinger Brüel & Kjær) and Luna Innovations are actively participating in standardization efforts, contributing technical expertise to working groups and pilot studies. These companies are also collaborating with regulatory bodies to ensure that their FBG biosensors meet both current and anticipated requirements for safety, accuracy, and data integrity. For example, Luna Innovations has reported ongoing work with healthcare partners to validate FBG-based sensors for real-time patient monitoring, aligning with both FDA and European Medicines Agency (EMA) expectations.

Looking ahead, the next few years are expected to bring further convergence of international standards, with increased emphasis on interoperability, data security, and lifecycle management. The European Union’s Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) are anticipated to influence global best practices, prompting manufacturers worldwide to enhance their quality management systems and post-market surveillance capabilities. As FBG biosensing technologies mature, industry stakeholders are calling for the development of dedicated standards that address the full spectrum of biosensor applications, from point-of-care diagnostics to industrial bioprocess monitoring.

Market Size, Segmentation, and 2025–2030 Growth Forecasts

Fiber Bragg-based biosensing technologies are poised for significant growth between 2025 and 2030, driven by increasing demand for real-time, label-free, and multiplexed biosensing solutions across healthcare, environmental monitoring, and industrial applications. The market is segmented by application (medical diagnostics, environmental monitoring, food safety, and industrial process control), end-user (hospitals, research institutes, environmental agencies, and manufacturing), and geography (North America, Europe, Asia-Pacific, and Rest of World).

In 2025, the global market for fiber Bragg grating (FBG) biosensors is expected to reach a value in the low hundreds of millions USD, with a compound annual growth rate (CAGR) projected in the high single to low double digits through 2030. This growth is underpinned by the unique advantages of FBG biosensors, such as immunity to electromagnetic interference, high sensitivity, and the ability to perform distributed sensing over long distances. The medical diagnostics segment is anticipated to account for the largest share, propelled by the need for rapid, point-of-care testing and continuous patient monitoring. Environmental monitoring is also a fast-growing segment, as regulatory bodies and industries seek more sensitive and robust detection of pollutants and pathogens.

Key players in the fiber Bragg-based biosensing market include Hottinger Brüel & Kjær (HBK), which offers advanced FBG interrogation systems and sensing solutions, and Luna Innovations, a leader in fiber optic sensing platforms with applications in both healthcare and industrial sectors. Microsens SA specializes in custom FBG sensors for biomedical and environmental applications, while Optical Solutions Group (OSG) in Japan is expanding its portfolio to include biosensing modules for integration into diagnostic devices. These companies are investing in R&D to enhance sensor specificity, miniaturization, and integration with digital health platforms.

Geographically, North America and Europe are expected to maintain leading positions due to strong healthcare infrastructure, early adoption of advanced sensing technologies, and robust R&D ecosystems. However, Asia-Pacific is projected to exhibit the fastest growth, fueled by expanding healthcare access, increased environmental monitoring initiatives, and government support for smart manufacturing.

Looking ahead, the market outlook for 2025–2030 is shaped by ongoing technological advancements, such as the integration of FBG biosensors with microfluidics and wireless data transmission, as well as the development of multiplexed platforms capable of detecting multiple biomarkers simultaneously. Strategic collaborations between sensor manufacturers, medical device companies, and research institutions are expected to accelerate commercialization and adoption, positioning fiber Bragg-based biosensing technologies as a cornerstone of next-generation diagnostic and monitoring solutions.

Competitive Analysis: Company Strategies and Partnerships

The competitive landscape for fiber Bragg-based biosensing technologies in 2025 is characterized by a dynamic interplay of established photonics manufacturers, emerging biosensor startups, and strategic collaborations with research institutions. As the demand for highly sensitive, real-time, and multiplexed biosensing solutions grows—driven by healthcare diagnostics, environmental monitoring, and food safety—companies are intensifying their focus on innovation, integration, and market expansion.

Key industry players such as Hottinger Brüel & Kjær (HBK) and Luna Innovations have leveraged their expertise in fiber optic sensing to develop advanced Bragg grating interrogation systems. These companies are increasingly targeting the biosensing segment by adapting their core technologies for biocompatible coatings and surface functionalization, enabling selective detection of biomolecules. Luna Innovations, for example, has expanded its product portfolio to include solutions tailored for life sciences and medical diagnostics, often in partnership with academic research centers.

Meanwhile, European firms such as HBM FiberSensing (a subsidiary of HBK) and Osensa Innovations are investing in R&D to enhance the sensitivity and multiplexing capabilities of their fiber Bragg grating (FBG) sensors. These efforts are supported by collaborations with universities and public research organizations, aiming to accelerate the translation of laboratory prototypes into commercial biosensing platforms.

Startups and SMEs are also playing a pivotal role. Companies like Optics11 are developing miniaturized FBG-based biosensors for point-of-care diagnostics and in vivo monitoring. Their strategies often involve forming partnerships with medical device manufacturers and clinical research organizations to validate and scale their technologies for regulatory approval and market entry.

Strategic alliances are a hallmark of the sector in 2025. Cross-sector partnerships—linking photonics companies, biotechnology firms, and healthcare providers—are facilitating the integration of FBG biosensors into broader diagnostic and monitoring systems. For instance, several companies are collaborating with hospital networks and pharmaceutical companies to pilot FBG-based biosensing in clinical trials, aiming to demonstrate real-world efficacy and cost-effectiveness.

Looking ahead, the competitive outlook suggests continued consolidation and collaboration. Companies are expected to pursue joint ventures and licensing agreements to access proprietary surface chemistries, expand geographic reach, and accelerate time-to-market. The convergence of photonics, biotechnology, and digital health is likely to drive further innovation, positioning fiber Bragg-based biosensing technologies as a cornerstone of next-generation diagnostic and monitoring solutions.

Challenges, Risks, and Barriers to Adoption

Fiber Bragg-based biosensing technologies, while promising for real-time, label-free, and multiplexed detection in medical diagnostics and environmental monitoring, face several challenges and barriers to widespread adoption as of 2025. These hurdles span technical, economic, and regulatory domains, impacting both the pace and scale of commercialization.

A primary technical challenge is the integration of biorecognition elements onto the fiber surface without compromising the sensor’s sensitivity or stability. Achieving robust, reproducible surface functionalization remains complex, especially for long-term or in vivo applications. Issues such as biofouling, where nonspecific adsorption of biomolecules degrades sensor performance, persist despite advances in surface chemistry. Additionally, the miniaturization and multiplexing of Fiber Bragg Grating (FBG) arrays, while theoretically feasible, often encounter cross-sensitivity to temperature and strain, complicating signal interpretation in dynamic environments.

Manufacturing scalability is another significant barrier. The precision required for inscribing Bragg gratings and the subsequent functionalization steps can lead to high production costs and variability between batches. Companies such as FBGS Technologies GmbH and Luna Innovations, both recognized for their expertise in FBG sensor manufacturing, are actively working to streamline fabrication processes and improve yield. However, the transition from laboratory prototypes to mass-produced, application-specific biosensors is still in its early stages.

From a regulatory perspective, biosensors intended for clinical or food safety applications must meet stringent standards for accuracy, reproducibility, and biocompatibility. The lack of harmonized international standards for fiber optic biosensors complicates the approval process, often resulting in lengthy and costly validation cycles. This is particularly relevant for companies aiming to enter regulated markets such as the United States or the European Union.

Economic factors also play a role. The initial investment in specialized interrogation equipment and the need for skilled personnel to interpret complex optical signals can deter adoption, especially in resource-limited settings. While companies like Hottinger Brüel & Kjær (HBK) and Optical Solutions Group offer advanced FBG interrogation systems, the cost-benefit ratio for biosensing applications is still being evaluated by end-users.

Looking ahead, overcoming these challenges will require coordinated efforts in materials science, engineering, and regulatory policy. Advances in nanofabrication, surface chemistry, and integrated photonics are expected to address some technical barriers, while industry consortia and standardization bodies may help streamline regulatory pathways. The next few years will be critical in determining whether fiber Bragg-based biosensing technologies can transition from niche research tools to mainstream diagnostic and monitoring solutions.

Future Outlook: Emerging Opportunities and Strategic Recommendations

Fiber Bragg-based biosensing technologies are poised for significant advancements and market expansion in 2025 and the coming years, driven by the convergence of photonics, biotechnology, and digital health. These sensors, which utilize Fiber Bragg Gratings (FBGs) to detect minute changes in refractive index or strain, are increasingly recognized for their high sensitivity, multiplexing capability, and immunity to electromagnetic interference. The future outlook is shaped by several key trends and strategic opportunities.

First, the integration of FBG biosensors into point-of-care diagnostics and wearable health monitoring devices is accelerating. Companies such as Hottinger Brüel & Kjær (HBK), a leader in fiber optic sensing, are actively developing compact, robust FBG sensor platforms suitable for medical and biotechnological applications. These platforms are expected to enable real-time, continuous monitoring of biomarkers such as glucose, lactate, and various proteins, supporting the shift toward personalized medicine and remote patient care.

Second, the expansion of FBG biosensing into environmental and food safety monitoring is anticipated. Organizations like Luna Innovations are advancing FBG interrogation systems that can be adapted for detecting pathogens, toxins, or contaminants in water and food supplies. This diversification is supported by the inherent multiplexing ability of FBG arrays, allowing simultaneous detection of multiple analytes with a single optical fiber.

Third, the miniaturization and integration of FBG biosensors with microfluidic and lab-on-chip technologies are expected to drive new applications in drug discovery and high-throughput screening. Companies such as FBGS Technologies are at the forefront of developing specialty optical fibers and grating inscription techniques that enhance sensor performance and facilitate integration into compact analytical devices.

Looking ahead, strategic recommendations for stakeholders include investing in interdisciplinary R&D collaborations to accelerate the translation of FBG biosensing from laboratory prototypes to commercial products. Partnerships between photonics companies, medical device manufacturers, and healthcare providers will be crucial for regulatory approval and clinical adoption. Additionally, standardization efforts led by industry bodies such as the Optica (formerly OSA) will be important to ensure interoperability and quality assurance across the sector.

In summary, the next few years will likely see fiber Bragg-based biosensing technologies move from niche research tools to mainstream solutions in healthcare, environmental monitoring, and beyond. Companies that prioritize innovation, cross-sector collaboration, and regulatory readiness will be best positioned to capitalize on these emerging opportunities.

Sources & References

- Hottinger Brüel & Kjær

- Luna Innovations

- FBGS Technologies

- Micron Optics

- IEEE

- Optical Solutions Group (OSG)

- Sensuron

- Smartec SA

- International Organization for Standardization

- Osensa Innovations

- Optics11