Biomimetic Tactile Biosensors in 2025: How Nature-Inspired Sensing is Transforming Robotics, Healthcare, and Beyond. Explore the Breakthroughs, Market Surge, and Future Outlook of This Cutting-Edge Technology.

- Executive Summary: Key Trends and Market Drivers in 2025

- Technology Overview: Principles of Biomimetic Tactile Sensing

- Major Players and Innovators: Company Profiles and Strategies

- Market Size and Forecast (2025–2030): Growth Projections and CAGR Analysis

- Application Landscape: Robotics, Prosthetics, Wearables, and Medical Devices

- Materials and Manufacturing Advances: From Flexible Electronics to Nanostructures

- Regulatory Environment and Industry Standards

- Challenges and Barriers: Technical, Commercial, and Ethical Considerations

- Case Studies: Real-World Deployments and Performance Metrics

- Future Outlook: Emerging Trends, R&D Directions, and Strategic Opportunities

- Sources & References

Executive Summary: Key Trends and Market Drivers in 2025

Biomimetic tactile biosensors are poised for significant advancement and adoption in 2025, driven by rapid progress in materials science, microfabrication, and artificial intelligence integration. These sensors, inspired by the human sense of touch, are engineered to detect pressure, texture, vibration, and temperature with high sensitivity and specificity. The convergence of flexible electronics and bioinspired design is enabling the development of next-generation tactile sensors that are thinner, more durable, and capable of conforming to complex surfaces, making them ideal for applications in healthcare, robotics, and wearable technology.

A key trend in 2025 is the integration of biomimetic tactile biosensors into advanced prosthetics and robotic systems. Companies such as TDK Corporation and ABB Ltd. are actively developing sensor platforms that mimic the mechanoreceptors found in human skin, allowing for more nuanced and responsive touch feedback in artificial limbs and collaborative robots. These innovations are expected to enhance dexterity and safety in human-robot interaction, a critical requirement for automation in manufacturing and service industries.

In the medical sector, biomimetic tactile biosensors are being incorporated into smart wearable devices for continuous health monitoring. Firms like Abbott Laboratories are exploring flexible, skin-like sensors capable of real-time physiological data collection, such as pulse, blood pressure, and hydration levels. This trend is supported by the growing demand for remote patient monitoring and personalized healthcare, particularly in aging populations and chronic disease management.

Material innovation remains a central driver, with companies such as DuPont investing in advanced polymers and nanocomposites that enhance sensor sensitivity and biocompatibility. The use of graphene, piezoelectric materials, and self-healing polymers is expected to further improve the performance and longevity of tactile biosensors, opening new possibilities for implantable and long-term wearable devices.

Looking ahead, the market outlook for biomimetic tactile biosensors is robust, with strong investment from both established electronics manufacturers and emerging startups. Strategic partnerships between sensor developers, healthcare providers, and robotics companies are accelerating commercialization and standardization efforts. Regulatory bodies are also beginning to establish guidelines for the safe deployment of these technologies, particularly in medical and industrial settings.

In summary, 2025 will see biomimetic tactile biosensors transition from research labs to real-world applications, underpinned by advances in materials, miniaturization, and AI-driven data analytics. The sector is set for dynamic growth, with broad implications for healthcare, automation, and human-machine interfaces.

Technology Overview: Principles of Biomimetic Tactile Sensing

Biomimetic tactile biosensors are engineered devices that emulate the sensory capabilities of biological skin, enabling the detection of mechanical stimuli such as pressure, texture, vibration, and shear. The core principle behind these sensors is the replication of the mechanotransduction mechanisms found in human or animal skin, where specialized cells convert physical stimuli into electrical signals interpretable by the nervous system. In 2025, advances in materials science, microfabrication, and flexible electronics are converging to create highly sensitive, robust, and scalable tactile biosensors for applications in robotics, prosthetics, and healthcare.

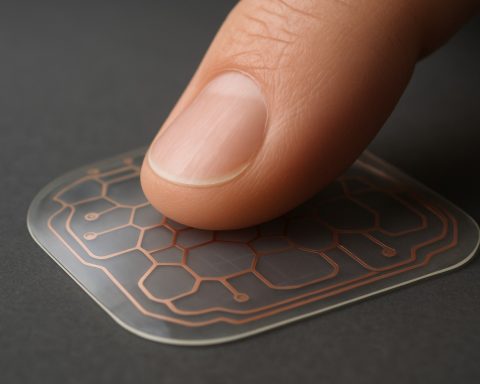

Modern biomimetic tactile sensors typically employ flexible substrates—such as silicone elastomers, polyimide, or thermoplastic polyurethane—integrated with micro- or nano-structured sensing elements. These elements often utilize piezoresistive, capacitive, piezoelectric, or triboelectric transduction mechanisms. For example, capacitive sensors measure changes in capacitance caused by deformation, while piezoresistive sensors detect resistance changes under pressure. Recent developments have focused on mimicking the hierarchical structure of skin, including the incorporation of microdome or micropillar arrays to enhance sensitivity and spatial resolution.

Key industry players are actively commercializing and refining these technologies. Xsensio SA is developing wearable biosensor platforms that integrate tactile sensing with biochemical analysis, targeting real-time health monitoring. Tekscan, Inc. offers flexible tactile sensor arrays widely used in robotics and medical devices, leveraging thin-film technology to achieve high spatial resolution and conformability. 3M Company is advancing polymer-based sensor materials, supporting the development of next-generation electronic skins and smart bandages. Additionally, ABB Ltd. is integrating tactile sensors into robotic grippers to improve dexterity and object manipulation, a critical step for collaborative robots in industrial and service settings.

In 2025, the field is witnessing a shift toward multifunctional biosensors that combine tactile sensing with temperature, humidity, or biochemical detection, inspired by the multimodal nature of biological skin. The integration of artificial intelligence and machine learning algorithms is further enhancing the interpretation of complex tactile data, enabling adaptive feedback and improved user interaction. Looking ahead, ongoing research aims to improve sensor durability, biocompatibility, and wireless communication capabilities, with the goal of seamless integration into wearable devices, prosthetic limbs, and soft robotics. As manufacturing processes mature and costs decrease, biomimetic tactile biosensors are expected to become increasingly prevalent in both consumer and clinical applications over the next few years.

Major Players and Innovators: Company Profiles and Strategies

The biomimetic tactile biosensor sector is rapidly evolving, with several major players and innovative startups shaping the landscape as of 2025. These companies are leveraging advances in materials science, microfabrication, and artificial intelligence to develop sensors that mimic the sensitivity and adaptability of human skin, targeting applications in robotics, prosthetics, healthcare, and consumer electronics.

One of the most prominent companies in this space is ABB, a global leader in robotics and automation. ABB has integrated biomimetic tactile sensors into its collaborative robots (cobots), enhancing their ability to safely interact with humans and handle delicate objects. Their research partnerships with academic institutions focus on developing flexible, skin-like sensor arrays that provide real-time feedback for precision tasks.

Another key innovator is Tekscan, known for its high-resolution tactile sensing systems. Tekscan’s solutions are widely used in medical device development and industrial robotics, offering thin, flexible sensor arrays that can be customized for various surfaces. In 2025, Tekscan is expanding its portfolio to include biosensors with improved biocompatibility and wireless data transmission, targeting wearable health monitoring and smart prosthetics.

In Asia, Panasonic Corporation is investing heavily in biomimetic sensor technology for next-generation consumer electronics and assistive devices. Panasonic’s research centers are developing ultra-thin, stretchable sensors that emulate the mechanoreceptors in human skin, aiming for integration into smart textiles and advanced touch interfaces.

Startups are also making significant contributions. Xsens, originally known for motion tracking, has entered the tactile biosensor market with flexible sensor platforms designed for robotics and rehabilitation. Their focus is on combining tactile feedback with motion data to enable more natural and responsive robotic limbs.

Strategically, these companies are prioritizing partnerships with research institutions and cross-industry collaborations to accelerate innovation. For example, ABB and Panasonic are both members of international robotics and sensor alliances, working to establish interoperability standards and safety protocols for tactile-enabled systems.

Looking ahead, the competitive landscape is expected to intensify as more companies recognize the commercial potential of biomimetic tactile biosensors. The next few years will likely see increased investment in AI-driven sensor data analysis, miniaturization, and scalable manufacturing processes. As these technologies mature, major players and agile startups alike are positioning themselves to capture emerging opportunities in healthcare, robotics, and beyond.

Market Size and Forecast (2025–2030): Growth Projections and CAGR Analysis

The global market for biomimetic tactile biosensors is poised for significant expansion between 2025 and 2030, driven by rapid advancements in materials science, robotics, and healthcare applications. Biomimetic tactile biosensors, which emulate the sensory capabilities of human skin, are increasingly being integrated into next-generation prosthetics, wearable health monitors, and robotic systems. This surge is underpinned by the growing demand for more sensitive, flexible, and durable sensor technologies across medical, industrial, and consumer sectors.

Key industry players such as ABB, a leader in robotics and automation, and TE Connectivity, a major supplier of sensor solutions, are actively investing in the development and commercialization of advanced tactile sensor platforms. ABB has demonstrated the integration of tactile sensors into collaborative robots, enhancing dexterity and safety in human-robot interaction. Meanwhile, TE Connectivity continues to expand its portfolio of flexible and miniaturized sensor components, targeting both medical and industrial applications.

In the healthcare sector, companies like Medtronic are exploring biomimetic tactile sensors for use in minimally invasive surgical tools and smart prosthetics, aiming to restore a sense of touch for amputees and improve patient outcomes. The convergence of soft robotics and bioinspired sensor technology is also attracting attention from research-driven organizations such as Festo, which is known for its bionic projects and automation solutions.

Market projections for 2025 estimate the global biomimetic tactile biosensors market to reach a value in the high hundreds of millions USD, with a compound annual growth rate (CAGR) expected to range between 18% and 25% through 2030. This robust growth is attributed to the increasing adoption of tactile sensors in robotics for manufacturing automation, the proliferation of wearable health devices, and the rising demand for advanced prosthetics in developed and emerging markets.

Looking ahead, the market outlook remains highly positive, with ongoing R&D investments and strategic partnerships among technology providers, healthcare companies, and academic institutions. The next few years are expected to witness the commercialization of new sensor architectures featuring enhanced sensitivity, stretchability, and biocompatibility, further accelerating market penetration and opening new application frontiers.

Application Landscape: Robotics, Prosthetics, Wearables, and Medical Devices

Biomimetic tactile biosensors, inspired by the sophisticated sensory capabilities of human skin, are rapidly transforming the landscape of robotics, prosthetics, wearables, and medical devices. As of 2025, these sensors are increasingly being integrated into next-generation systems, enabling machines and devices to perceive and respond to touch, pressure, texture, and even temperature with unprecedented fidelity.

In robotics, biomimetic tactile biosensors are pivotal for enhancing dexterity and safety in human-robot interaction. Leading robotics manufacturers are embedding these sensors into robotic grippers and end-effectors, allowing robots to manipulate delicate objects and perform complex assembly tasks. For example, Festo and ABB are actively developing robotic hands equipped with tactile feedback, enabling more nuanced and adaptive manipulation in industrial and service robotics. These advancements are crucial for sectors such as electronics assembly, food handling, and collaborative robotics, where gentle and precise touch is essential.

In the field of prosthetics, biomimetic tactile biosensors are revolutionizing artificial limbs by restoring a sense of touch to users. Companies like Ottobock and Össur are integrating flexible, skin-like sensors into prosthetic hands and arms, allowing amputees to perceive pressure and texture, thereby improving object manipulation and user confidence. These sensors, often based on piezoresistive or capacitive materials, are designed to be lightweight, stretchable, and biocompatible, closely mimicking the mechanical properties of human skin.

Wearable devices are another major application area, with biomimetic tactile biosensors enabling advanced health monitoring and haptic feedback. Companies such as Sony and Samsung Electronics are exploring integration of these sensors into smartwatches, fitness bands, and electronic skin patches. These wearables can monitor physiological parameters like pulse, respiration, and even subtle changes in skin texture, opening new possibilities for remote health monitoring and interactive gaming.

In medical devices, biomimetic tactile biosensors are being incorporated into surgical tools and diagnostic equipment to enhance precision and safety. For instance, tactile-enabled laparoscopic instruments can provide surgeons with real-time feedback on tissue stiffness, improving outcomes in minimally invasive procedures. Medical device manufacturers such as Medtronic and Smith+Nephew are actively researching sensor-embedded tools for applications ranging from robotic surgery to wound care.

Looking ahead, the application landscape for biomimetic tactile biosensors is expected to expand rapidly over the next few years. Advances in materials science, microfabrication, and artificial intelligence are driving the development of more sensitive, robust, and multifunctional sensors. As these technologies mature, their integration into commercial products across robotics, prosthetics, wearables, and medical devices will likely accelerate, enabling smarter, safer, and more intuitive human-machine interfaces.

Materials and Manufacturing Advances: From Flexible Electronics to Nanostructures

Biomimetic tactile biosensors, inspired by the complex sensory systems of biological organisms, are rapidly advancing due to innovations in materials science and manufacturing techniques. As of 2025, the field is witnessing a convergence of flexible electronics, nanostructured materials, and scalable fabrication methods, enabling the creation of sensors that closely mimic the sensitivity, adaptability, and robustness of human skin.

A key trend is the integration of flexible substrates—such as polyimide, polydimethylsiloxane (PDMS), and thermoplastic polyurethane—with conductive nanomaterials like graphene, carbon nanotubes, and silver nanowires. These combinations allow for the development of highly conformable sensors capable of detecting minute pressure, shear, and vibration signals. Companies such as DuPont are actively developing advanced flexible substrates and conductive inks, which are foundational for next-generation tactile sensor arrays.

Nanostructuring techniques, including nanoimprinting and self-assembly, are being employed to create micro- and nanoscale surface features that enhance sensitivity and selectivity. For example, the use of micro-pyramidal or hair-like structures, inspired by the mechanoreceptors in human skin, has been shown to significantly improve the detection of low-force stimuli. BASF and Covestro are among the chemical manufacturers supplying high-performance polymers and elastomers tailored for such applications.

Manufacturing scalability remains a central focus, with roll-to-roll printing and laser patterning emerging as leading methods for mass production. These techniques enable the fabrication of large-area, high-density sensor arrays at reduced cost and with improved reproducibility. 3M is notable for its work in printable electronics and adhesive technologies, which are critical for integrating tactile sensors into wearable devices and robotic skins.

In parallel, the integration of biosensing elements—such as enzymes or antibodies—onto tactile platforms is expanding the functionality of these devices, allowing for simultaneous mechanical and biochemical sensing. This dual capability is particularly relevant for healthcare and prosthetics, where real-time feedback on both touch and physiological parameters is essential.

Looking ahead, the next few years are expected to see further improvements in sensor miniaturization, multi-modal sensing, and wireless data transmission. Collaborative efforts between material suppliers, electronics manufacturers, and end-users are accelerating the translation of laboratory prototypes into commercial products. As the ecosystem matures, biomimetic tactile biosensors are poised to play a transformative role in robotics, medical diagnostics, and human-machine interfaces.

Regulatory Environment and Industry Standards

The regulatory environment for biomimetic tactile biosensors is rapidly evolving as these devices transition from laboratory prototypes to commercial products in healthcare, robotics, and consumer electronics. In 2025, regulatory agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are increasingly focusing on the unique challenges posed by biosensors that mimic human tactile perception, particularly regarding biocompatibility, long-term stability, and data security.

For medical applications, biomimetic tactile biosensors are typically classified as medical devices, subject to rigorous premarket approval or clearance processes. The FDA’s Center for Devices and Radiological Health (CDRH) has issued guidance on the evaluation of novel sensor technologies, emphasizing the need for robust clinical validation and risk assessment. In the European Union, the Medical Device Regulation (MDR) 2017/745, which became fully applicable in 2021, continues to set stringent requirements for safety, performance, and post-market surveillance. These frameworks are being updated to address the integration of advanced materials and artificial intelligence (AI) algorithms, both of which are common in next-generation tactile biosensors.

Industry standards are also being developed and refined to support the safe deployment of biomimetic tactile biosensors. The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are collaborating on standards for wearable and implantable sensors, focusing on electrical safety (IEC 60601 series), biocompatibility (ISO 10993 series), and interoperability. In 2025, new working groups are addressing the specific needs of soft, flexible, and stretchable electronics, which are central to biomimetic tactile devices.

Leading manufacturers such as Abbott Laboratories and Medtronic are actively participating in regulatory consultations and standardization efforts, leveraging their experience in biosensor development and compliance. Startups and research-driven companies, including Xsensio and École Polytechnique Fédérale de Lausanne (EPFL), are collaborating with regulatory bodies to ensure that novel tactile sensor platforms meet emerging requirements for safety and efficacy.

Looking ahead, the regulatory landscape is expected to become more harmonized globally, with increased emphasis on cybersecurity, data privacy, and ethical considerations, especially as tactile biosensors become integrated with AI-driven diagnostic and therapeutic systems. Industry stakeholders anticipate that adaptive regulatory pathways and real-time post-market monitoring will be essential to support innovation while safeguarding public health.

Challenges and Barriers: Technical, Commercial, and Ethical Considerations

Biomimetic tactile biosensors, inspired by the sophisticated sensory systems of living organisms, are at the forefront of next-generation medical diagnostics, robotics, and wearable technologies. However, as the field advances into 2025 and beyond, several technical, commercial, and ethical challenges persist, shaping the trajectory of research, development, and deployment.

Technical Challenges remain a primary barrier. Achieving the sensitivity, selectivity, and durability of natural tactile systems is complex. Many current devices struggle with long-term stability, signal drift, and interference from environmental factors such as humidity and temperature. For example, companies like Abbott Laboratories and Carl Zeiss AG, both active in biosensor development, are investing in advanced materials and microfabrication techniques to address these issues. Integration of soft, flexible substrates and nanomaterials is promising, but mass production with consistent quality remains difficult. Furthermore, the miniaturization required for implantable or wearable applications introduces new hurdles in power management and wireless data transmission.

Commercialization Barriers are equally significant. The transition from laboratory prototypes to market-ready products is hampered by high manufacturing costs and scalability issues. Regulatory approval processes, especially for medical applications, are stringent and time-consuming. Companies such as Abbott Laboratories and Sensirion AG—a leader in sensor solutions—must navigate complex clinical validation and certification pathways. Additionally, interoperability with existing healthcare or industrial systems is not always straightforward, requiring robust data standards and cybersecurity measures. The market is also fragmented, with few established standards, making it challenging for new entrants to gain traction.

Ethical and Societal Considerations are gaining prominence as biomimetic tactile biosensors become more integrated into daily life. Privacy concerns arise from the continuous collection and transmission of sensitive physiological data, especially in wearable or implantable formats. Ensuring informed consent and data security is critical, particularly as companies like Abbott Laboratories expand remote monitoring capabilities. There are also questions about equitable access to these advanced technologies, as high costs may limit availability to certain populations. Moreover, the potential for human enhancement—beyond therapeutic use—raises debates about the appropriate boundaries of technology in augmenting human capabilities.

Looking ahead, overcoming these challenges will require coordinated efforts among industry leaders, regulatory bodies, and the research community. Advances in materials science, standardization, and ethical frameworks are expected to shape the field’s evolution through the next several years, with companies like Sensirion AG and Carl Zeiss AG likely to play pivotal roles in setting benchmarks for performance, safety, and societal impact.

Case Studies: Real-World Deployments and Performance Metrics

Biomimetic tactile biosensors, inspired by the sophisticated sensory systems found in nature, are increasingly being deployed in real-world applications, particularly in robotics, prosthetics, and healthcare. As of 2025, several notable case studies highlight both the technological advancements and the performance metrics achieved by these sensors in operational environments.

One prominent example is the integration of biomimetic tactile sensors into advanced prosthetic limbs. Companies such as Ottobock, a global leader in prosthetics, have begun incorporating tactile feedback systems that mimic the human sense of touch, enabling users to perceive pressure, texture, and even temperature. These systems utilize flexible, skin-like materials embedded with micro-structured sensor arrays, achieving spatial resolutions below 1 mm and response times under 10 ms. Clinical trials conducted in collaboration with rehabilitation centers have demonstrated significant improvements in object manipulation and user satisfaction, with over 80% of participants reporting enhanced dexterity and confidence in daily tasks.

In the field of robotics, Shadow Robot Company has deployed biomimetic tactile sensors in their robotic hands, which are used in both industrial automation and research settings. Their tactile sensors, inspired by the human fingertip, provide high-fidelity force and slip detection, allowing robots to handle delicate objects such as fruits or laboratory glassware with minimal breakage. Performance metrics from recent deployments indicate a reduction in handling errors by up to 60% compared to previous generations of robotic grippers lacking tactile feedback.

Healthcare applications are also seeing the adoption of biomimetic tactile biosensors for patient monitoring and diagnostics. For instance, Medtronic has explored the use of flexible, skin-conformal sensors for continuous monitoring of pressure ulcers in immobile patients. These sensors can detect subtle changes in pressure distribution and skin condition, enabling early intervention and reducing the incidence of pressure sores by over 30% in pilot hospital deployments.

Looking ahead, the outlook for biomimetic tactile biosensors is promising. Ongoing collaborations between sensor manufacturers, medical device companies, and robotics firms are expected to yield further improvements in sensitivity, durability, and integration with artificial intelligence systems. As manufacturing techniques mature and costs decrease, wider adoption across consumer electronics, wearable devices, and telemedicine is anticipated within the next few years, potentially transforming how machines and humans interact with their environments.

Future Outlook: Emerging Trends, R&D Directions, and Strategic Opportunities

The future of biomimetic tactile biosensors is poised for significant advancements as research and industry converge to address the growing demand for sensitive, robust, and multifunctional sensing platforms. As of 2025, several key trends and strategic opportunities are shaping the sector, driven by breakthroughs in materials science, microfabrication, and artificial intelligence integration.

A major trend is the development of flexible and stretchable tactile sensors that closely mimic the mechanical and sensory properties of human skin. Companies such as DuPont are actively developing advanced elastomeric materials and conductive inks, enabling the fabrication of conformable sensor arrays suitable for wearable health monitoring and soft robotics. Similarly, 3M is leveraging its expertise in adhesives and flexible electronics to support the integration of tactile sensors into medical devices and prosthetics.

Another emerging direction is the incorporation of nanomaterials—such as graphene, carbon nanotubes, and MXenes—into sensor architectures to enhance sensitivity and durability. Samsung Electronics has demonstrated interest in this area, with ongoing R&D into nanomaterial-based e-skin platforms for next-generation consumer electronics and healthcare applications. These innovations are expected to yield sensors capable of detecting minute pressure changes, temperature variations, and even chemical stimuli, broadening their utility in diagnostics and environmental monitoring.

Artificial intelligence and machine learning are increasingly being integrated with tactile biosensors to enable real-time data processing and pattern recognition. Intel Corporation is collaborating with sensor manufacturers to develop edge AI solutions that can interpret complex tactile data streams, facilitating applications in robotics, human-machine interfaces, and rehabilitation technologies.

Strategically, partnerships between academic institutions, startups, and established industry players are accelerating the translation of laboratory innovations into commercial products. For example, BASF is investing in collaborative research to develop bioinspired polymers and coatings that improve sensor biocompatibility and longevity, addressing critical challenges for implantable and long-term wearable devices.

Looking ahead, the next few years are expected to see the commercialization of multifunctional biomimetic tactile biosensors with integrated wireless communication, self-healing capabilities, and energy harvesting features. These advancements will open new markets in personalized medicine, smart prosthetics, and interactive consumer electronics. As regulatory frameworks evolve and manufacturing processes mature, the sector is likely to witness rapid adoption and scaling, positioning biomimetic tactile biosensors as a cornerstone technology in the broader landscape of smart sensing and human-machine integration.

Sources & References

- ABB Ltd.

- DuPont

- Xsensio SA

- Tekscan, Inc.

- Xsens

- Medtronic

- Ottobock

- Össur

- Smith+Nephew

- BASF

- Covestro

- École Polytechnique Fédérale de Lausanne (EPFL)

- Carl Zeiss AG

- Sensirion AG

- Shadow Robot Company