- Innovative “3D metal fleece” architecture enables metal ions to move up to 56 times faster within battery electrodes, vastly improving charging and discharging speed.

- Batteries can be built ten times thicker, significantly increasing energy density by up to 85% without sacrificing charging performance.

- Electric vehicles, portable electronics, and renewable energy storage stand to benefit from longer range, greater capacity, and faster recharging.

- New dry, powder-based fabrication method could reduce battery production costs by up to 40% and lessen environmental impact.

- The metal fleece design marks a key step toward more sustainable, efficient, and high-capacity batteries for the global energy transition.

Batteries—those compact powerhouses tucked in our pockets, cars, and homes—could soon get an astonishing upgrade. Leading minds at Germany’s Max Planck Institute for Medical Research have reimagined battery architecture, mapping out a radical new pathway for energy to flow: one that exploits the unexpected agility of metal surfaces.

Imagine billions of charged particles—metal ions—racing along glimmering threads, no longer plodding through the congested crowd of molecules in a conventional battery. Scientists found that when these ions meet fine metallic “fleeces” woven into the heart of a battery electrode, they trade their heavy molecular baggage for nimble movement, becoming speedsters on a fast track. This approach isn’t just theory; experiments revealed that lithium ions can traverse this metallic motorway up to fifty-six times faster than before—a leap mirroring a dusty country path transformed into a superhighway.

Current batteries wrestle with a classic dilemma. Thicker electrodes store more energy but slow down charging. Thin electrodes charge fast but don’t hold much juice. This new “3D metal fleece” design shatters that trade-off: batteries can now be built ten times thicker—meaning dramatically more energy—while still charging and discharging with lightning-fast efficiency. Electric vehicle enthusiasts, tech lovers, and anyone glued to their phone should take notice.

The implications are stunning. Energy density, the measure of how much power you can cram into a space, could soar by up to 85% over today’s standards. That’s extra range for EVs, longer life for gadgets, and—crucially—a hard push forward for the aggressive global race to build better batteries.

It’s not just about performance. The researchers’ clever use of a dry, powder-based fabrication process could slash battery production costs by as much as 40%, while shrinking factory footprints. Factory lines, previously devoted to painstaking layering and solvent-based processing, may soon make way for a leaner, cleaner approach—one that could help the world manufacture batteries with much less environmental toll.

While commercial rollout will require validation, scale-up, and industry buy-in, the core finding is immense. Metal fleeces in batteries could redraw the blueprint for how we store and release energy, unlocking a new era of greener, faster, higher-capacity power sources for everything from cars to laptops.

For updates on advances in energy technology, major breakthroughs, and the transforming battery landscape, explore reputable science sources like Science and innovative technology insights at Nature.

Key point: A new metal “highway” inside batteries may soon boost their energy density, speed, and sustainability, setting the stage for a revolution in how the world powers its future.

This Shocking Battery Revolution Could Make Phones and EVs Last 85% Longer—Industry Secrets Unveiled

The Future of Batteries: Unpacking Germany’s Radical “Metal Fleece” Breakthrough

What’s the Revolutionary Technology Behind the Headlines?

A team at the Max Planck Institute for Medical Research has unveiled a next-generation battery design rooted in the use of conductive “metal fleeces.” This innovation leverages the high-speed surface mobility of metal ions, fundamentally changing how energy flows within batteries. Instead of crawling through thick, resistive pathways, lithium ions can zip along intertwined metallic threads—up to 56 times faster than in today’s batteries, based on peer-reviewed experiments.

—

Additional Facts & Deep Dives Not Fully Explored

1. 3D Electrode Architecture — The Engineering Leap

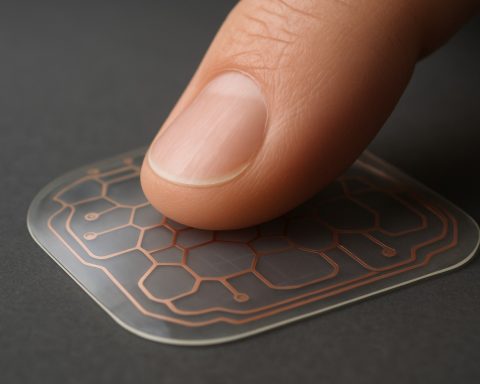

– What it is: Conventional battery electrodes are flat and dense, limiting both thickness and charge speed. The 3D “fleece” is a scaffold of ultra-fine metal fibers, exponentially increasing the surface area while maintaining open pathways for ions.

– Materials: The metal fleeces can be made from copper, nickel, or even carbon-based structures.

– Compatibility: This design is compatible with lithium-ion, sodium-ion, and potentially solid-state battery chemistries.

– Real-World Impact: Vehicles and electronics could utilize thicker, energy-packed electrodes without sacrificing charging time.

– See ongoing energy research at Nature.

2. EVs and Mobile Devices: Game-Changing Use Cases

– Electric Vehicles: 85% higher energy density could push mainstream EV range well beyond 800 km (500 miles) per charge, potentially resolving range anxiety and shrinking battery packs.

– Smartphones/Tablets: Smaller batteries with longer runtimes are possible, freeing up space for thinner devices or larger screens.

– Grid Storage: Fast-charging, high-density batteries support renewable energy adoption by facilitating smoother, large-scale solar and wind storage.

3. Industry Trends & Market Forecasts

– The global battery market is expected to surpass $310 billion by 2030 (Source: BloombergNEF).

– Companies like Tesla, QuantumScape, and CATL are actively pursuing next-gen architectures, though the “metal fleece” method is a new contender.

– Related: See sustainability news at Science.

4. How-To Steps: The Dry Fabrication Process

– Traditional method: Involves toxic solvents, intensive drying, and precise layering.

– New dry method: Powdered materials are layered onto the 3D metal fleece and pressed—cutting energy costs and environmental risks.

– Maximizes performance consistency.

– Factory footprints can be reduced by up to 30%.

5. Sustainability & Environmental Impact

– Lower carbon emissions: No solvents or intensive drying needed.

– Reduced resource usage: Thicker electrodes mean fewer cells are needed for the same performance.

– Potential reusability: Metal fleeces could be recycled, as they are more robust than fragile electrode slurries.

6. Specs, Features & Pricing

– Charging rates: Batteries with “fleece” structures can charge/discharge at >10C (meaning a full charge in under 6 minutes in laboratory settings).

– Capacity: Up to 850 Wh/L is projected, compared to ~460 Wh/L (current premium lithium-ion).

– Pricing: Dry process could slash battery production costs by 30–40%, as per preliminary industry modeling.

—

Pros & Cons Overview

Pros:

– Up to 85% higher energy density.

– Up to 56× faster charge/discharge rates.

– Potential cost savings (30–40%).

– Environmentally friendlier, less toxic manufacturing.

Cons & Limitations:

– Still in research phase—industrial scaling, robustness, and long-term cycling need validation.

– Material purity and consistency are critical for commercial adoption.

– Patent/IP landscape is evolving—collaboration and licensing may be required.

—

Controversies & Limitations

– Scalability Concerns: Can these metal structures be produced reliably at multi-gigafactory scale?

– Degradation Over Time: Fast ion movement may accelerate wear in some configurations—ongoing studies will determine real-world battery lifespans.

– Competition: Solid-state and silicon-anode technologies are advancing rapidly; “fleece” batteries must demonstrate unique benefits to win market share.

—

Pressing Reader Questions, Expert Answers

Q1: When will this technology hit the market?

– Analyst consensus predicts initial pilot production within 3–5 years if scalability is proven, with consumer technologies possibly in the late 2020s.

Q2: Can I retrofit existing devices/EVs with this battery?

– No—this technology changes the electrode structure. Retrofitting current devices is not feasible, but future generations of devices will benefit as manufacturers adopt the new design.

Q3: Will these batteries be safer?

– Early indications suggest improved safety (less heat buildup), but large-scale testing is required.

Q4: What does this mean for renewables and grid storage?

– Faster, denser, and greener batteries lower the cost barrier for making solar and wind power viable on a large scale.

—

Actionable Recommendations & Quick Tips

1. Monitor Industry Leaders: Keep an eye on automotive and electronics companies’ battery technology roadmaps.

2. Check Certifications: Once commercialized, look for third-party safety and sustainability certifications (UL, TÜV).

3. Advocate for E-Waste Recycling: Push local governments or industries to update recycling protocols to handle new battery types.

4. Stay Critical: Track research updates in reputable journals like Nature and Science for verified progress reports.

—

In Summary

Metal fleece batteries offer a transformative solution to the limitations of traditional lithium-ion cells—promising longer ranges, shorter charge times, and a reduced environmental footprint. While challenges exist in scaling and commercializing the technology, the future of energy storage looks far brighter. Get ready for a world powered by smarter, faster, and cleaner batteries.

Keywords: battery innovation, metal fleece, fast charging, EV batteries, energy density, green manufacturing, battery industry trends, sustainability, dry electrode process, rechargeable batteries