Unveiling Self-Oscillating Gels: How Autonomous Motion is Revolutionizing Smart Materials. Discover the Science, Applications, and Future Impact of These Dynamic Polymers. (2025)

- Introduction to Self-Oscillating Gels: Definition and Historical Context

- Core Mechanisms: Chemical and Physical Principles Behind Autonomous Oscillation

- Key Material Components: Polymers, Catalysts, and Responsive Elements

- Breakthrough Research and Pioneering Experiments

- Current and Emerging Applications in Medicine, Robotics, and Sensing

- Manufacturing Techniques and Scalability Challenges

- Market Growth and Public Interest: Trends and Forecasts (Estimated 20–30% CAGR through 2030)

- Comparative Analysis: Self-Oscillating Gels vs. Other Smart Materials

- Regulatory, Safety, and Environmental Considerations

- Future Outlook: Technological Advancements and Potential Societal Impact

- Sources & References

Introduction to Self-Oscillating Gels: Definition and Historical Context

Self-oscillating gels are a class of smart materials capable of undergoing autonomous, periodic changes in their physical properties—such as shape, volume, or color—without the need for external, repetitive stimuli. Unlike conventional responsive gels that require continuous external triggers (e.g., temperature, pH, or light) to induce changes, self-oscillating gels harness internal chemical reactions to drive rhythmic transformations. These materials are typically based on polymer networks integrated with chemical oscillators, most notably the Belousov-Zhabotinsky (BZ) reaction, which is a well-known example of a non-equilibrium chemical oscillator.

The concept of self-oscillating gels emerged from the intersection of polymer chemistry, materials science, and nonlinear chemical dynamics. The foundational work in this field can be traced back to the late 20th century, when researchers began exploring the integration of oscillatory chemical reactions into polymer matrices. In the early 1990s, the pioneering studies by Japanese scientists, particularly the group led by Professor Yoshihito Osada at the University of Tokyo, demonstrated the first self-oscillating gel systems. These early gels incorporated ruthenium complexes as catalysts within poly(N-isopropylacrylamide) (PNIPAAm) hydrogels, enabling the BZ reaction to drive periodic swelling and deswelling cycles.

The historical development of self-oscillating gels was motivated by the desire to create materials that mimic biological rhythms and autonomous motion observed in living systems, such as the beating of a heart or the peristaltic movement of intestines. This biomimetic inspiration has guided research toward designing gels that can convert chemical energy directly into mechanical work, without the need for external control. Over the past three decades, advances in polymer synthesis, catalyst design, and understanding of nonlinear chemical kinetics have expanded the range of self-oscillating gel systems and their potential applications.

Today, self-oscillating gels are studied for their potential in soft robotics, artificial muscles, autonomous actuators, and smart drug delivery systems. Their unique ability to perform work in a pre-programmed, rhythmic manner makes them attractive for applications where traditional actuation methods are impractical. Research in this area is supported by leading scientific organizations and academic institutions worldwide, including the RIKEN research institute in Japan, which is renowned for its contributions to advanced materials science, and the National Science Foundation in the United States, which funds interdisciplinary research in chemistry and materials engineering.

Core Mechanisms: Chemical and Physical Principles Behind Autonomous Oscillation

Self-oscillating gels are a class of soft materials capable of undergoing spontaneous, periodic changes in their physical properties—such as volume, shape, or color—without the need for external periodic stimuli. The core mechanisms underlying these autonomous oscillations are rooted in the interplay between chemical reactions and the physical properties of polymer networks. Understanding these mechanisms is crucial for advancing applications in soft robotics, artificial muscles, and biomimetic systems.

At the heart of self-oscillating gels is the integration of a chemical oscillator within a responsive polymer matrix. The most widely studied chemical oscillator in this context is the Belousov-Zhabotinsky (BZ) reaction, a well-known example of a non-equilibrium chemical system that exhibits periodic changes in redox state. When a BZ catalyst, such as ruthenium bipyridine complex, is covalently bonded to a polymer network (commonly poly(N-isopropylacrylamide), or PNIPAAm), the periodic redox changes induce corresponding changes in the hydrophilicity and swelling behavior of the gel. This coupling enables the gel to autonomously swell and shrink in a rhythmic fashion, effectively converting chemical energy into mechanical motion.

The chemical principle driving this behavior is the feedback loop inherent in the BZ reaction. The oscillatory production and consumption of intermediates, such as bromous acid and ferroin, create periodic shifts in the oxidation state of the catalyst. These redox changes alter the polymer’s affinity for water: in the oxidized state, the gel may become more hydrophilic and swell, while in the reduced state, it becomes more hydrophobic and contracts. This cyclical process is sustained as long as the chemical fuel (typically malonic acid and an oxidizer) is supplied, allowing for continuous, autonomous oscillation.

Physically, the polymer network’s structure and crosslinking density play a significant role in determining the amplitude and frequency of oscillation. The network must be sufficiently flexible to accommodate volume changes, yet robust enough to maintain integrity over many cycles. The diffusion of reactants and products within the gel also influences the spatial and temporal characteristics of the oscillations, sometimes leading to complex behaviors such as traveling chemical waves or spatial pattern formation.

Research into self-oscillating gels is multidisciplinary, involving expertise in polymer chemistry, physical chemistry, and materials science. Leading academic institutions and research organizations, such as RIKEN in Japan, have been at the forefront of developing and characterizing these materials. Their work has elucidated the fundamental principles that govern autonomous oscillation and paved the way for innovative applications in soft matter engineering.

Key Material Components: Polymers, Catalysts, and Responsive Elements

Self-oscillating gels are a class of smart materials capable of autonomous, periodic changes in their physical properties—such as swelling, shrinking, or bending—without the need for external stimuli. The unique behavior of these gels is rooted in their carefully engineered material components, which include specific polymers, catalysts, and responsive elements. Understanding these key components is essential for advancing the design and application of self-oscillating gels in fields such as soft robotics, drug delivery, and artificial muscles.

The primary structural component of self-oscillating gels is the polymer network. Most commonly, these gels are based on poly(N-isopropylacrylamide) (PNIPAAm), a thermoresponsive polymer known for its ability to undergo reversible volume phase transitions in response to temperature changes. PNIPAAm provides the necessary flexibility and hydrophilicity, allowing the gel to absorb and expel water as its internal environment changes. The polymer network is often crosslinked to maintain structural integrity during repeated oscillations.

A defining feature of self-oscillating gels is the incorporation of a catalyst that drives an internal chemical reaction, typically the Belousov-Zhabotinsky (BZ) reaction. The BZ reaction is a well-known oscillating chemical process that can produce periodic changes in redox state and pH. To harness this reaction within a gel, a metal catalyst—most frequently ruthenium(II) tris(bipyridine) complex—is covalently bonded to the polymer backbone. This immobilized catalyst enables the BZ reaction to occur within the gel matrix, generating rhythmic chemical changes that translate into mechanical motion. The use of ruthenium complexes is particularly advantageous due to their strong redox activity and compatibility with the BZ reaction cycle.

Responsive elements are also integral to the function of self-oscillating gels. These elements are molecular groups or moieties within the polymer network that respond to the chemical oscillations generated by the catalyst. For example, the redox state changes induced by the BZ reaction can alter the hydrophilicity of the polymer, causing the gel to swell or shrink in a periodic manner. The careful design of these responsive elements ensures that the gel’s mechanical response is tightly coupled to the internal chemical oscillations, enabling autonomous actuation.

The synergy between the polymer matrix, the embedded catalyst, and the responsive elements is what enables self-oscillating gels to function as autonomous, dynamic materials. Ongoing research by leading academic institutions and organizations such as RIKEN in Japan and Massachusetts Institute of Technology continues to refine these components, paving the way for more efficient and versatile self-oscillating systems.

Breakthrough Research and Pioneering Experiments

Self-oscillating gels represent a remarkable class of smart materials capable of autonomous, periodic motion without external mechanical or electrical stimuli. The foundation of these materials lies in the integration of chemical oscillators—most notably, the Belousov-Zhabotinsky (BZ) reaction—into polymer networks. Over the past two decades, research in this field has accelerated, with 2025 marking a year of significant breakthroughs and pioneering experiments that have advanced both the fundamental understanding and practical potential of self-oscillating gels.

A major milestone in 2025 was achieved by research teams in Japan, building on the foundational work of Professor Ryo Yoshida at the University of Tokyo. Yoshida’s group has long been recognized for developing poly(N-isopropylacrylamide)-based gels that incorporate the BZ reaction, enabling rhythmic swelling and deswelling cycles. In 2025, the team reported a new generation of self-oscillating gels with enhanced amplitude and frequency control, achieved by fine-tuning the catalyst distribution and crosslinking density within the polymer matrix. This innovation allowed for more precise synchronization of gel motion, opening avenues for soft robotics and autonomous actuators.

Another pioneering experiment was conducted by researchers at the RIKEN research institute, one of Japan’s largest and most prestigious scientific organizations. Their 2025 study demonstrated the integration of self-oscillating gels with microfluidic devices, enabling the creation of autonomous micro-pumps and valves. By harnessing the periodic volume changes of the gel, the team achieved controlled fluid transport without external power sources, a breakthrough for lab-on-a-chip technologies and biomedical applications.

In Europe, collaborative efforts led by the French National Centre for Scientific Research (CNRS) focused on the theoretical modeling of self-oscillating gel dynamics. Their 2025 publications provided new insights into the coupling between chemical kinetics and mechanical deformation, using advanced computational simulations to predict complex spatiotemporal patterns. These models are crucial for designing gels with tailored oscillatory behaviors for specific applications.

Collectively, the 2025 breakthroughs in self-oscillating gel research have not only deepened scientific understanding but also paved the way for practical innovations in soft robotics, autonomous fluidics, and responsive biomedical devices. The synergy between experimental advances and theoretical modeling, as demonstrated by leading institutions such as the University of Tokyo, RIKEN, and CNRS, continues to drive the field toward real-world applications.

Current and Emerging Applications in Medicine, Robotics, and Sensing

Self-oscillating gels represent a class of smart materials capable of autonomous, periodic motion without external stimuli, driven by internal chemical reactions—most notably, the Belousov-Zhabotinsky (BZ) reaction. Their unique ability to convert chemical energy directly into mechanical work has positioned them at the forefront of innovation in medicine, robotics, and sensing technologies.

In medicine, self-oscillating gels are being explored for their potential in drug delivery systems and artificial muscles. Their rhythmic swelling and deswelling can be harnessed to create pulsatile drug release platforms, enabling precise temporal control over medication administration. This is particularly promising for therapies requiring synchronized dosing or responsive delivery in reaction to physiological cues. Additionally, the gels’ biomimetic actuation properties are under investigation for use in soft actuators and artificial muscles, which could lead to advanced prosthetics and responsive implants. Research institutions and organizations such as National Institutes of Health have supported studies into smart hydrogels for biomedical applications, highlighting the clinical relevance of these materials.

In the field of robotics, self-oscillating gels are paving the way for the development of soft robots and autonomous actuators. Unlike traditional rigid robots, soft robots made from these gels can perform complex, life-like movements without the need for external power sources or intricate control systems. This opens up possibilities for minimally invasive surgical tools, adaptive grippers, and micro-robots capable of navigating confined or delicate environments. The integration of self-oscillating gels into robotic systems is being actively researched by leading academic and scientific organizations, including Massachusetts Institute of Technology, which is renowned for its work in soft robotics and smart materials.

- Medical Devices: Self-oscillating gels are being designed for use in implantable pumps, artificial muscles, and responsive wound dressings.

- Soft Robotics: Their autonomous actuation enables the creation of untethered, adaptive robots for exploration, manipulation, and biomedical applications.

- Sensing Technologies: The periodic motion of these gels can be coupled with transducers to develop self-powered sensors for monitoring environmental or physiological parameters.

Emerging research is also investigating the use of self-oscillating gels in biosensing, where their rhythmic behavior can be modulated by specific analytes, enabling real-time detection of biological or chemical signals. As the field advances, collaborations between materials scientists, engineers, and clinicians—supported by organizations such as the National Science Foundation—are expected to accelerate the translation of self-oscillating gel technologies from laboratory prototypes to real-world applications.

Manufacturing Techniques and Scalability Challenges

Self-oscillating gels represent a class of smart materials capable of autonomous, periodic motion without external stimuli, driven by internal chemical reactions—most notably, the Belousov-Zhabotinsky (BZ) reaction. Their unique ability to convert chemical energy directly into mechanical work has attracted significant interest for applications in soft robotics, artificial muscles, and biomimetic devices. However, translating laboratory-scale demonstrations into practical, scalable manufacturing processes presents several technical and logistical challenges.

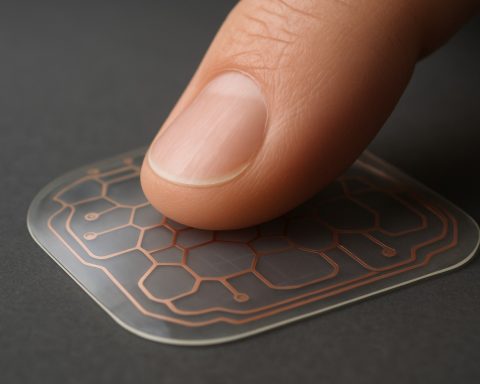

The synthesis of self-oscillating gels typically involves the copolymerization of a responsive polymer network—such as poly(N-isopropylacrylamide) (PNIPAAm)—with a catalyst for the BZ reaction, often ruthenium complexes. Achieving uniform distribution of the catalyst and precise control over the gel’s microstructure is critical for consistent oscillatory behavior. Conventional batch polymerization methods, while suitable for small-scale research, often result in heterogeneities and limited reproducibility when scaled up. To address this, researchers are exploring advanced manufacturing techniques such as microfluidic synthesis, which allows for precise control over gel size, shape, and composition, and 3D printing, which enables the fabrication of complex architectures with spatially programmed oscillatory domains.

Despite these advances, several scalability challenges remain. First, the cost and availability of catalysts—particularly ruthenium-based compounds—pose economic and environmental concerns for large-scale production. Efforts are underway to identify alternative catalysts or to recycle and reuse existing ones, but these approaches are still in early stages. Second, the integration of self-oscillating gels into functional devices requires robust encapsulation and interfacing strategies to maintain chemical gradients and prevent catalyst leaching, which can degrade performance over time. Third, the long-term stability and durability of the gels under repeated oscillatory cycles must be ensured, as mechanical fatigue and chemical degradation can limit their operational lifespan.

- Process optimization: Continuous-flow reactors and automated polymerization systems are being developed to improve batch-to-batch consistency and throughput.

- Material innovation: Research into alternative, more abundant catalysts and environmentally benign monomers is ongoing to reduce costs and improve sustainability.

- Device integration: Advances in soft lithography and hybrid material assembly are facilitating the incorporation of self-oscillating gels into microscale devices and actuators.

Organizations such as RIKEN in Japan and leading academic institutions are at the forefront of developing scalable manufacturing techniques for self-oscillating gels, leveraging interdisciplinary expertise in chemistry, materials science, and engineering. As research progresses, overcoming these manufacturing and scalability challenges will be crucial for the widespread adoption of self-oscillating gels in next-generation soft devices.

Market Growth and Public Interest: Trends and Forecasts (Estimated 20–30% CAGR through 2030)

Self-oscillating gels, a class of smart materials capable of autonomous rhythmic motion without external stimuli, are gaining significant traction in both academic and industrial sectors. These materials, often based on polymer networks incorporating catalysts for the Belousov-Zhabotinsky (BZ) reaction, have demonstrated unique potential for applications in soft robotics, artificial muscles, and responsive biomedical devices. The growing interest in self-oscillating gels is reflected in the increasing number of research initiatives and collaborative projects spearheaded by leading scientific organizations and universities worldwide.

Market analyses and expert consensus suggest that the global market for self-oscillating gels and related smart materials is poised for robust expansion, with an estimated compound annual growth rate (CAGR) of 20–30% projected through 2030. This growth is driven by several converging factors: advances in polymer chemistry, the miniaturization of soft actuators, and the rising demand for adaptive materials in healthcare, robotics, and microfluidics. The integration of self-oscillating gels into next-generation devices is expected to accelerate as research transitions from laboratory-scale demonstrations to scalable manufacturing processes.

Key research institutions, such as RIKEN in Japan and Massachusetts Institute of Technology (MIT) in the United States, have been at the forefront of developing novel self-oscillating gel systems and exploring their practical applications. RIKEN, a prominent Japanese research institute, has published extensively on the design and synthesis of autonomous polymer actuators, while MIT has contributed to the understanding of dynamic material systems and their integration into soft robotics. These efforts are complemented by collaborative projects funded by governmental agencies, including the National Science Foundation (NSF), which supports fundamental research in smart materials and adaptive systems.

Public interest in self-oscillating gels is also on the rise, as evidenced by the growing number of patents, conference presentations, and interdisciplinary workshops dedicated to smart materials and soft matter physics. The American Physical Society (APS) and the American Chemical Society (ACS) regularly feature sessions on self-oscillating gels at their annual meetings, highlighting the expanding community of researchers and industry stakeholders. As the field matures, partnerships between academia and industry are expected to play a pivotal role in translating laboratory breakthroughs into commercial products, further fueling market growth and public engagement.

Comparative Analysis: Self-Oscillating Gels vs. Other Smart Materials

Self-oscillating gels represent a unique class of smart materials distinguished by their ability to undergo autonomous, periodic changes in shape or volume without the need for external stimuli once initiated. This behavior is typically driven by internal chemical reactions, such as the Belousov-Zhabotinsky (BZ) reaction, which provides a continuous source of energy for rhythmic motion. In a comparative context, self-oscillating gels offer several advantages and limitations when measured against other smart materials, including shape-memory alloys, electroactive polymers, and thermoresponsive hydrogels.

Unlike traditional stimuli-responsive materials that require external triggers—such as heat, light, electric fields, or magnetic fields—to induce a response, self-oscillating gels are capable of sustained, autonomous actuation. For example, shape-memory alloys (SMAs) like Nitinol require thermal cycling to transition between phases and achieve actuation. While SMAs are known for their high mechanical strength and large recoverable strains, their reliance on external heating limits their application in autonomous systems. In contrast, self-oscillating gels can maintain rhythmic motion as long as the internal chemical fuel is present, making them attractive for applications in soft robotics and artificial muscles where continuous, untethered operation is desirable.

Electroactive polymers (EAPs) are another class of smart materials that deform in response to electrical stimulation. EAPs offer rapid response times and can be precisely controlled via electrical signals, which is advantageous for applications requiring high-speed actuation. However, their dependence on external power sources and complex control systems can be a drawback in scenarios where autonomy and simplicity are prioritized. Self-oscillating gels, by contrast, eliminate the need for external wiring or power supplies, enabling more compact and integrated designs.

Thermoresponsive hydrogels, such as those based on poly(N-isopropylacrylamide), swell or shrink in response to temperature changes. These materials are widely used in drug delivery and tissue engineering due to their biocompatibility and tunable properties. However, their actuation is typically slow and limited to the presence of thermal gradients. Self-oscillating gels, while sharing the soft and biocompatible nature of hydrogels, surpass them in terms of dynamic, periodic actuation without the need for fluctuating environmental conditions.

Despite these advantages, self-oscillating gels face challenges related to the sustainability of their internal chemical reactions, the need for continuous fuel supply, and the relatively low mechanical output compared to metallic or polymeric actuators. Ongoing research, often supported by leading scientific organizations such as the National Science Foundation and collaborative efforts at institutions like RIKEN, is focused on improving the efficiency, longevity, and scalability of these materials. As the field advances, self-oscillating gels are expected to complement, rather than replace, other smart materials, offering unique solutions for autonomous, rhythmic actuation in soft robotics, biomedical devices, and adaptive systems.

Regulatory, Safety, and Environmental Considerations

Self-oscillating gels, a class of smart materials capable of autonomous rhythmic motion without external stimuli, are increasingly attracting attention for their potential applications in soft robotics, drug delivery, and artificial muscles. As these materials transition from laboratory research to practical deployment, regulatory, safety, and environmental considerations become paramount.

From a regulatory perspective, self-oscillating gels are subject to oversight depending on their intended use. For biomedical applications, such as drug delivery systems or implantable devices, these materials must comply with stringent safety and efficacy standards set by authorities like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These agencies require comprehensive preclinical and clinical testing to assess biocompatibility, toxicity, and long-term stability. The unique dynamic behavior of self-oscillating gels—often driven by chemical reactions such as the Belousov-Zhabotinsky reaction—necessitates additional scrutiny to ensure that oscillatory byproducts or degradation products do not pose unforeseen risks to human health.

For non-medical applications, such as in soft robotics or actuators, regulatory frameworks may be less defined but still require adherence to general chemical safety standards. Organizations like the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) in the European Union provide guidelines for the safe handling, storage, and disposal of chemicals used in the synthesis and operation of self-oscillating gels. Manufacturers must ensure that all components, including catalysts and monomers, are registered and evaluated for occupational exposure risks.

Environmental considerations are also critical, particularly as the production and disposal of self-oscillating gels scale up. The environmental impact depends on the chemical composition of the gels, the persistence of their components, and the potential for bioaccumulation or ecotoxicity. Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and ECHA require environmental risk assessments for new chemical substances, including evaluation of degradation pathways and the fate of any persistent or hazardous byproducts. Sustainable design principles—such as the use of biodegradable polymers and green chemistry approaches—are increasingly encouraged to minimize environmental footprint.

In summary, the regulatory, safety, and environmental landscape for self-oscillating gels is shaped by their intended application and chemical makeup. Ongoing collaboration between material scientists, regulatory agencies, and environmental authorities is essential to ensure that these innovative materials are developed and deployed responsibly, safeguarding both human health and the environment.

Future Outlook: Technological Advancements and Potential Societal Impact

Self-oscillating gels represent a frontier in the development of smart materials, with the potential to revolutionize multiple sectors by 2025 and beyond. These unique polymeric systems are capable of autonomous, periodic motion without external stimuli, typically powered by chemical reactions such as the Belousov-Zhabotinsky (BZ) reaction. As research advances, the future outlook for self-oscillating gels is marked by both technological breakthroughs and significant societal implications.

Technologically, the next generation of self-oscillating gels is expected to feature enhanced responsiveness, programmability, and integration with electronic and biological systems. Researchers are focusing on improving the efficiency and durability of these gels, enabling them to operate under a wider range of environmental conditions and for longer durations. Innovations in polymer chemistry and nanotechnology are anticipated to yield gels with tunable oscillation frequencies, amplitudes, and functionalities, paving the way for their use in soft robotics, artificial muscles, and adaptive biomedical devices. For instance, self-oscillating gels could be engineered to mimic natural muscle contractions, offering new solutions for prosthetics and minimally invasive surgical tools.

The integration of self-oscillating gels with microelectromechanical systems (MEMS) and biohybrid devices is another promising direction. Such hybrid systems could lead to the development of autonomous actuators, sensors, and drug delivery platforms that respond dynamically to physiological cues. The potential for these materials to operate without external power sources aligns with the growing demand for sustainable and energy-efficient technologies. Leading research institutions and organizations, such as RIKEN in Japan, are at the forefront of exploring these applications, leveraging interdisciplinary expertise in chemistry, materials science, and bioengineering.

From a societal perspective, the widespread adoption of self-oscillating gels could have profound impacts. In healthcare, these materials may enable the creation of smart implants and responsive wound dressings that adapt to the healing process, improving patient outcomes and reducing the need for invasive interventions. In the field of robotics, soft machines powered by self-oscillating gels could safely interact with humans, opening new possibilities in elder care, rehabilitation, and collaborative manufacturing. Furthermore, the environmental benefits of self-sustaining, low-energy materials align with global sustainability goals championed by organizations such as the United Nations.

As research continues and interdisciplinary collaborations expand, the technological advancements in self-oscillating gels are poised to drive innovation across diverse fields, ultimately shaping a more adaptive, efficient, and sustainable society.

Sources & References

- RIKEN

- National Science Foundation

- Massachusetts Institute of Technology

- University of Tokyo

- French National Centre for Scientific Research (CNRS)

- National Institutes of Health

- American Chemical Society

- European Medicines Agency

- European Chemicals Agency

- United Nations