Maskless Lithography Systems Market Report 2025: In-Depth Analysis of Technology Advancements, Competitive Dynamics, and Global Growth Projections. Explore Key Drivers, Regional Trends, and Strategic Opportunities Shaping the Industry.

- Executive Summary & Market Overview

- Key Technology Trends in Maskless Lithography Systems

- Competitive Landscape and Leading Players

- Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

- Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Future Outlook: Emerging Applications and Innovation Pathways

- Challenges, Risks, and Strategic Opportunities

- Sources & References

Executive Summary & Market Overview

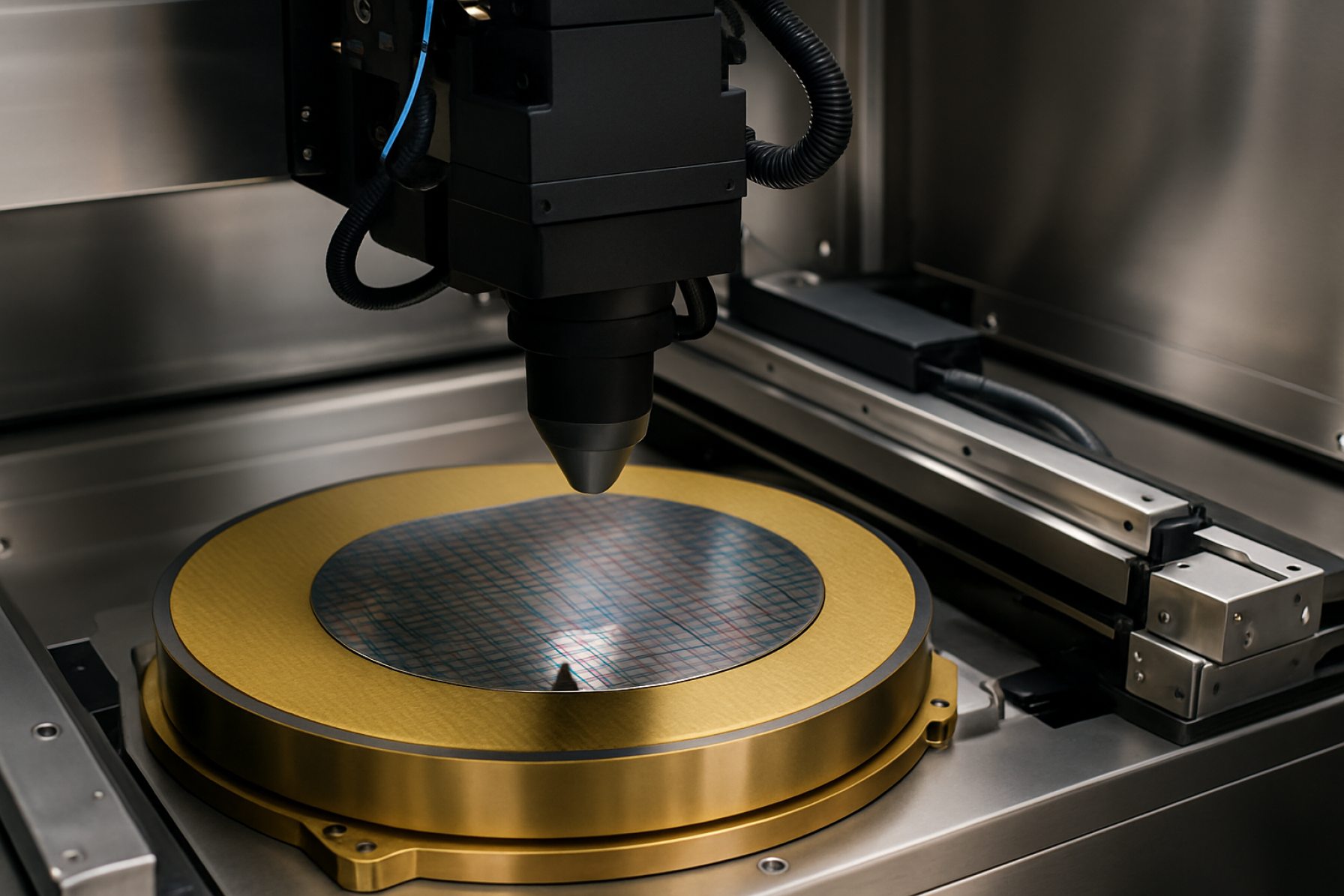

Maskless lithography systems represent a transformative technology in the field of semiconductor and microfabrication, enabling direct patterning of substrates without the need for physical photomasks. This approach offers significant advantages in terms of flexibility, cost reduction, and rapid prototyping, particularly as device geometries continue to shrink and customization demands rise. The global market for maskless lithography systems is poised for robust growth in 2025, driven by the increasing complexity of integrated circuits, the proliferation of advanced packaging, and the expansion of applications in photonics, MEMS, and biomedical devices.

According to recent industry analyses, the maskless lithography market is expected to achieve a compound annual growth rate (CAGR) exceeding 8% through 2025, with revenues projected to surpass USD 500 million globally. This growth is underpinned by the limitations of traditional photomask-based lithography, which faces escalating costs and longer lead times as feature sizes decrease. Maskless systems, leveraging technologies such as direct-write electron beam, laser beam, and digital light processing, are increasingly adopted for both R&D and low-to-medium volume manufacturing, where design flexibility and rapid iteration are critical.

Key players in the market, including Vistec Electron Beam, Heliotis Technologies, and Microtech, are investing in higher throughput and resolution capabilities to address the evolving needs of semiconductor foundries and research institutions. The Asia-Pacific region, led by China, Japan, and South Korea, is anticipated to dominate market share in 2025, fueled by aggressive investments in semiconductor manufacturing and government-backed innovation initiatives. North America and Europe remain significant markets, particularly in the context of advanced research and specialty device fabrication.

- Rising demand for heterogeneous integration and advanced packaging is accelerating adoption in the semiconductor sector.

- Maskless lithography is increasingly vital for rapid prototyping and small-batch production in photonics and MEMS.

- Ongoing R&D is focused on improving throughput, overlay accuracy, and compatibility with emerging materials.

In summary, maskless lithography systems are set to play a pivotal role in the next generation of microfabrication, offering a compelling alternative to traditional mask-based processes. The market outlook for 2025 is characterized by technological innovation, expanding application scope, and intensifying competition among established and emerging vendors.

Key Technology Trends in Maskless Lithography Systems

Maskless lithography systems are at the forefront of semiconductor manufacturing innovation, offering direct-write patterning capabilities that eliminate the need for costly photomasks. As the industry moves into 2025, several key technology trends are shaping the evolution and adoption of maskless lithography systems.

- Multi-Beam and Parallelization Advances: The integration of multi-beam electron and optical systems is significantly enhancing throughput, a traditional bottleneck for maskless lithography. Companies are deploying arrays of thousands of individually controlled beams, enabling high-speed, high-resolution patterning suitable for both prototyping and low-to-medium volume production. This approach is exemplified by the latest systems from Mapper Lithography and Vistec Electron Beam.

- AI-Driven Pattern Optimization: Artificial intelligence and machine learning algorithms are increasingly being used to optimize exposure strategies, correct for proximity effects, and reduce patterning errors. These advancements are improving yield and reducing the time required for process development, as highlighted in recent research from SEMI.

- Adoption of Advanced Light Sources: The shift towards deep ultraviolet (DUV) and extreme ultraviolet (EUV) wavelengths in maskless systems is enabling finer feature sizes and improved resolution. Innovations in laser and electron beam sources are expanding the application range of maskless lithography, particularly for advanced packaging and MEMS fabrication, according to TechInsights.

- Integration with Digital Manufacturing Ecosystems: Maskless lithography is increasingly being integrated into digital manufacturing workflows, supporting rapid design iterations and on-demand production. This trend is particularly relevant for the production of photonic devices, microfluidics, and custom ICs, as noted by Gartner.

- Cost and Sustainability Improvements: The elimination of photomasks not only reduces costs but also minimizes material waste and energy consumption. As sustainability becomes a greater priority in semiconductor manufacturing, maskless lithography’s lower environmental footprint is a key differentiator, as reported by imec.

These technology trends are positioning maskless lithography systems as a critical enabler for next-generation semiconductor devices, especially in applications demanding rapid prototyping, customization, and high-resolution patterning in 2025 and beyond.

Competitive Landscape and Leading Players

The competitive landscape for maskless lithography systems in 2025 is characterized by a mix of established semiconductor equipment giants and innovative niche players, each leveraging unique technological approaches to address the growing demand for flexible, high-resolution, and cost-effective patterning solutions. The market is driven by the need for rapid prototyping, advanced packaging, and the production of microelectromechanical systems (MEMS), photonics, and emerging applications in quantum computing and biomedical devices.

Key players in the maskless lithography market include Heidelberg Instruments, Microlithography Services Ltd., Vistec Electron Beam, and Nanoscribe GmbH. These companies have established strong portfolios in direct-write lithography, electron beam lithography (EBL), and two-photon polymerization (2PP) systems, catering to both research and industrial-scale production.

- Heidelberg Instruments is a market leader in maskless direct-write lithography, offering systems that support applications from rapid prototyping to volume manufacturing. Their MLA series is widely adopted in academic and industrial R&D labs for its flexibility and high throughput.

- Vistec Electron Beam specializes in high-resolution EBL systems, targeting advanced semiconductor nodes and nanofabrication. Their EBPG series is recognized for its precision and is used by leading foundries and research institutions.

- Nanoscribe GmbH focuses on 3D maskless lithography using two-photon polymerization, enabling the fabrication of complex micro- and nanostructures for photonics, micro-optics, and life sciences. Their Photonic Professional GT2 system is a benchmark in the field.

- Microlithography Services Ltd. provides custom maskless lithography solutions, particularly for MEMS and sensor applications, with a focus on flexibility and customer-specific requirements.

The competitive dynamics are further shaped by strategic partnerships, technology licensing, and investments in R&D. For instance, collaborations between equipment vendors and leading research institutes accelerate the development of next-generation maskless lithography platforms. Additionally, the entry of new players from regions such as Asia-Pacific, notably China and South Korea, is intensifying competition and driving innovation in cost-effective, high-throughput systems MarketsandMarkets.

Market Growth Forecasts (2025–2030): CAGR, Revenue, and Volume Analysis

The global market for maskless lithography systems is poised for robust growth between 2025 and 2030, driven by escalating demand for advanced semiconductor manufacturing, photonics, and microelectromechanical systems (MEMS). According to projections by MarketsandMarkets, the maskless lithography market is expected to register a compound annual growth rate (CAGR) of approximately 8.5% during this period. This growth is underpinned by the increasing adoption of direct-write lithography techniques in research and prototyping, as well as the push for cost-effective, flexible patterning solutions in the semiconductor industry.

Revenue forecasts indicate that the global market size, valued at around USD 450 million in 2025, could surpass USD 750 million by 2030. This expansion is attributed to the rising integration of maskless lithography systems in both academic and industrial settings, particularly for applications requiring rapid design iterations and customization, such as photonic integrated circuits and advanced packaging. The Asia-Pacific region, led by countries like China, Japan, and South Korea, is anticipated to dominate market share, fueled by significant investments in semiconductor fabrication and R&D infrastructure (Global Market Insights).

In terms of volume, unit shipments of maskless lithography systems are projected to grow steadily, with annual installations expected to increase from approximately 320 units in 2025 to over 500 units by 2030. This volume growth is supported by the proliferation of foundries and research institutions seeking alternatives to traditional photomask-based lithography, which is both costly and time-consuming for low- to medium-volume production (TechInsights).

- CAGR (2025–2030): ~8.5%

- Revenue (2025): USD 450 million

- Revenue (2030): USD 750+ million

- Unit Shipments (2025): ~320 units

- Unit Shipments (2030): 500+ units

Key market drivers include the miniaturization of electronic devices, the need for rapid prototyping, and the evolution of next-generation lithography technologies. As the industry continues to shift toward more agile and cost-efficient manufacturing processes, maskless lithography systems are expected to play an increasingly pivotal role in enabling innovation and reducing time-to-market for new semiconductor products.

Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

The regional landscape for maskless lithography systems in 2025 is shaped by varying levels of semiconductor industry maturity, R&D investment, and government support across North America, Europe, Asia-Pacific, and the Rest of the World.

- North America: North America, led by the United States, remains a pivotal market for maskless lithography systems due to its robust semiconductor manufacturing base and advanced research infrastructure. The region benefits from significant investments in next-generation chip fabrication and a strong presence of leading players such as Intel Corporation and TSMC’s U.S. operations. The U.S. government’s CHIPS Act and related incentives are expected to further accelerate adoption of advanced lithography technologies, including maskless systems, to enhance domestic chip production and reduce reliance on overseas supply chains (Semiconductor Industry Association).

- Europe: Europe’s market is characterized by a focus on research-driven innovation and specialty semiconductor applications. Countries such as Germany, the Netherlands, and France are home to key players like ASML Holding, which, while primarily known for photolithography, is also involved in maskless technology research. The European Union’s “Chips Act” and strategic initiatives to bolster semiconductor sovereignty are expected to drive demand for maskless lithography, particularly in prototyping, MEMS, and photonics sectors (European Commission).

- Asia-Pacific: Asia-Pacific dominates global semiconductor manufacturing, with countries such as Taiwan, South Korea, China, and Japan investing heavily in advanced lithography. The region’s rapid adoption of maskless lithography is propelled by the need for flexible, cost-effective solutions in both high-volume and specialty chip production. Major foundries like TSMC and Samsung Electronics are exploring maskless approaches for R&D and low-volume manufacturing, while China’s push for self-sufficiency is fostering domestic innovation in this segment (SEMI).

- Rest of World: In regions outside the major markets, adoption of maskless lithography systems is slower but growing, particularly in research institutions and emerging semiconductor hubs in the Middle East and Latin America. These regions are leveraging maskless systems for academic research, prototyping, and niche applications, often supported by international collaborations and technology transfer programs (Gartner).

Overall, while Asia-Pacific leads in volume, North America and Europe are key innovation centers, and the Rest of World is gradually expanding its footprint in maskless lithography, reflecting a globally diversified growth trajectory for 2025.

Future Outlook: Emerging Applications and Innovation Pathways

The future outlook for maskless lithography systems in 2025 is shaped by accelerating innovation and the emergence of new application domains beyond traditional semiconductor manufacturing. As the demand for advanced microfabrication grows, maskless lithography is increasingly recognized for its flexibility, rapid prototyping capabilities, and cost-effectiveness, particularly in low- to medium-volume production environments.

One of the most promising emerging applications is in the field of advanced packaging and heterogeneous integration. As chip designs become more complex, maskless lithography enables the direct writing of intricate interconnects and redistribution layers, supporting the development of 2.5D and 3D integrated circuits. This is particularly relevant for the production of chiplets and system-in-package (SiP) solutions, where design cycles are short and customization is critical. According to SEMI, the advanced packaging market is projected to grow at a CAGR of over 7% through 2025, with maskless lithography playing a key role in enabling rapid design iterations.

Another innovation pathway is in the realm of photonics and MEMS (Micro-Electro-Mechanical Systems). Maskless lithography systems are being adopted for the fabrication of photonic integrated circuits (PICs) and MEMS sensors, where design flexibility and the ability to quickly adapt to new layouts are essential. The direct-write approach eliminates the need for costly and time-consuming mask fabrication, making it ideal for R&D and small-batch production. Yole Group highlights that the photonics market is expected to see double-digit growth, with maskless lithography facilitating the prototyping and customization required for emerging applications in telecommunications, healthcare, and automotive sectors.

In addition, maskless lithography is gaining traction in the production of flexible electronics and wearable devices. The technology’s ability to pattern on non-planar and unconventional substrates opens new avenues for innovation in consumer electronics and medical devices. IDTechEx forecasts robust growth in the flexible electronics market, with maskless lithography systems enabling the rapid development of next-generation products.

Looking ahead to 2025, continued advancements in laser and electron-beam direct-write technologies are expected to further enhance resolution, throughput, and scalability. Strategic collaborations between equipment manufacturers, material suppliers, and end-users will likely accelerate the adoption of maskless lithography across diverse industries, positioning it as a cornerstone technology for the next wave of microfabrication innovation.

Challenges, Risks, and Strategic Opportunities

Maskless lithography systems, which eliminate the need for photomasks in semiconductor patterning, are gaining traction due to their flexibility and potential for cost reduction. However, the market in 2025 faces a complex landscape of challenges, risks, and strategic opportunities that will shape its trajectory.

Challenges and Risks

- Throughput Limitations: Despite advances, maskless lithography systems—especially those based on electron beam (e-beam) and direct-write technologies—struggle to match the high throughput of traditional photolithography. This bottleneck restricts their adoption in high-volume manufacturing, confining their use primarily to prototyping, R&D, and low-volume specialty applications (ASML).

- Resolution and Overlay Accuracy: Achieving the sub-10 nm resolutions required for advanced nodes remains a technical hurdle. Maintaining overlay accuracy across large wafers is particularly challenging, impacting yield and device performance (Semiconductor Industry Association).

- Capital and Operational Costs: While maskless systems reduce mask-related expenses, the high initial investment in equipment and the need for specialized maintenance can offset these savings, especially for smaller foundries (MarketsandMarkets).

- Technology Integration: Integrating maskless lithography into existing semiconductor fabs requires significant process adaptation and workforce retraining, posing operational risks and potential production delays.

Strategic Opportunities

- Customization and Rapid Prototyping: Maskless systems excel in applications demanding rapid design iterations, such as MEMS, photonics, and advanced packaging. This agility is increasingly valuable as product life cycles shorten and customization becomes a competitive differentiator (IDC).

- Emerging Markets: Growth in compound semiconductors, quantum devices, and flexible electronics presents new opportunities where maskless lithography’s flexibility and precision are advantageous (Gartner).

- Collaboration and Ecosystem Development: Strategic partnerships between equipment vendors, material suppliers, and foundries can accelerate technology maturation and adoption, mitigating some integration and cost challenges.

In summary, while maskless lithography systems face significant throughput and integration challenges in 2025, their unique strengths position them for growth in specialized and emerging semiconductor markets. Strategic investments and ecosystem collaboration will be critical to unlocking their full potential.

Sources & References

- Vistec Electron Beam

- TechInsights

- imec

- Nanoscribe GmbH

- MarketsandMarkets

- Global Market Insights

- Semiconductor Industry Association

- ASML Holding

- European Commission

- IDTechEx

- IDC