2025 Photolithography Equipment Manufacturing Industry Report: Market Dynamics, Technology Innovations, and Strategic Forecasts. Explore Key Growth Drivers, Regional Trends, and Competitive Insights Shaping the Next Five Years.

- Executive Summary & Market Overview

- Key Technology Trends in Photolithography Equipment (2025–2030)

- Competitive Landscape and Leading Players

- Market Growth Forecasts and CAGR Analysis (2025–2030)

- Regional Market Analysis: Opportunities and Hotspots

- Future Outlook: Emerging Applications and Investment Priorities

- Challenges, Risks, and Strategic Opportunities

- Sources & References

Executive Summary & Market Overview

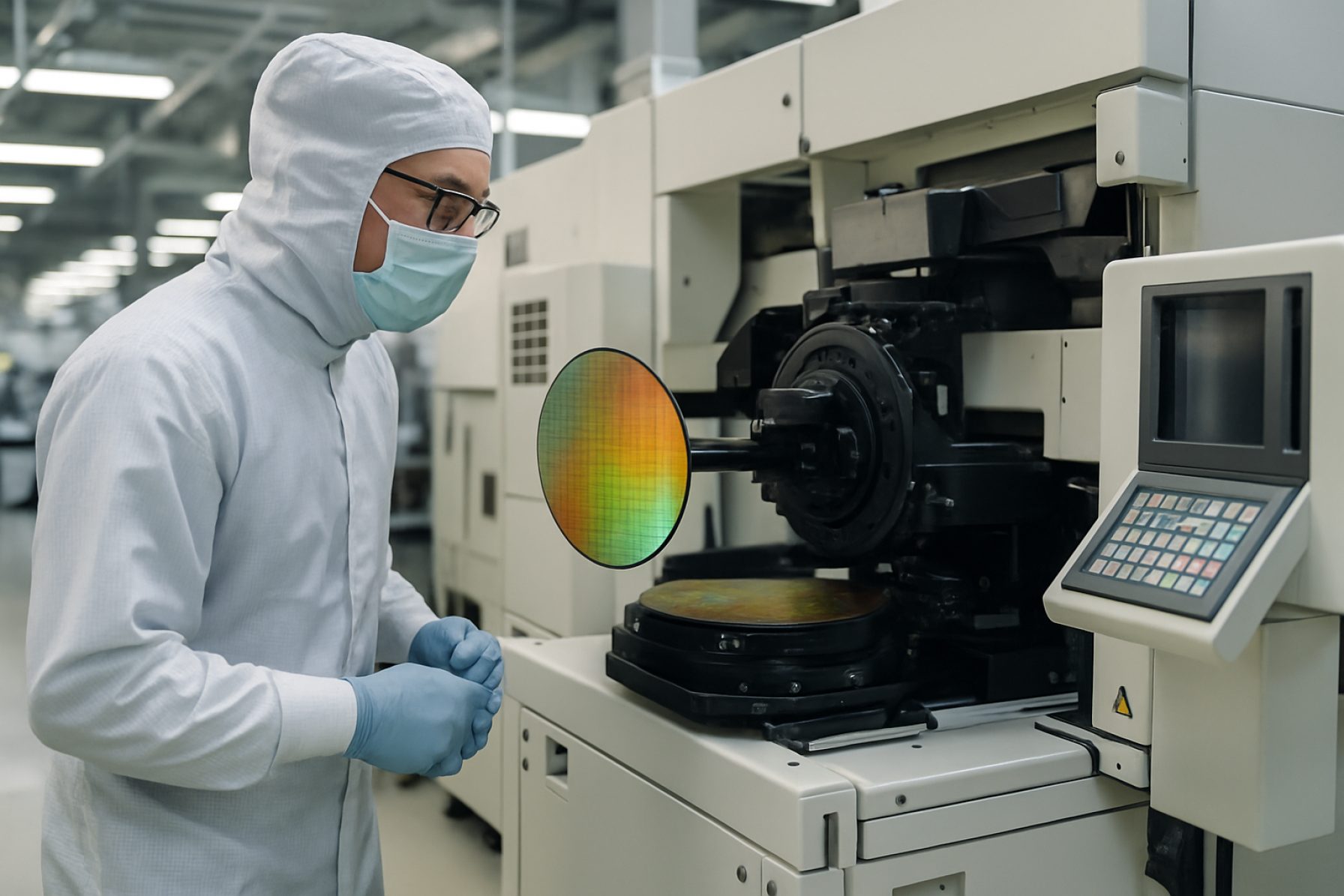

Photolithography equipment manufacturing is a critical segment within the semiconductor fabrication industry, enabling the precise patterning of integrated circuits on silicon wafers. As of 2025, the global photolithography equipment market is experiencing robust growth, driven by escalating demand for advanced chips in applications such as artificial intelligence, 5G, automotive electronics, and high-performance computing. The market is characterized by rapid technological advancements, particularly in extreme ultraviolet (EUV) lithography, which is essential for producing sub-7nm node semiconductors.

According to SEMI, the photolithography equipment market is projected to surpass $20 billion in 2025, reflecting a compound annual growth rate (CAGR) of approximately 8% from 2022 to 2025. This growth is underpinned by significant capital expenditures from leading foundries and integrated device manufacturers (IDMs) such as TSMC, Samsung Electronics, and Intel, all of which are aggressively investing in next-generation fabrication facilities.

The competitive landscape is highly concentrated, with ASML Holding maintaining a dominant position in EUV lithography, while Canon Inc. and Nikon Corporation continue to supply deep ultraviolet (DUV) systems. The transition to EUV technology is a key market driver, as it enables higher transistor densities and improved energy efficiency in advanced chips. However, the high cost and technical complexity of EUV systems present significant barriers to entry for new players.

Geopolitical factors, including export controls and supply chain disruptions, are influencing market dynamics. The United States, European Union, and Japan are implementing policies to secure domestic semiconductor manufacturing capabilities, which is expected to stimulate regional demand for photolithography equipment. Meanwhile, China is accelerating investments in domestic lithography technology to reduce reliance on foreign suppliers, as highlighted by ICWise.

In summary, the photolithography equipment manufacturing market in 2025 is defined by strong demand, rapid technological evolution, and strategic geopolitical maneuvering. The sector’s outlook remains positive, with innovation and capacity expansion at the forefront of industry priorities.

Key Technology Trends in Photolithography Equipment (2025–2030)

Between 2025 and 2030, photolithography equipment manufacturing is poised for significant transformation, driven by the semiconductor industry’s relentless pursuit of smaller nodes, higher yields, and cost efficiency. The most prominent trend is the rapid scaling and adoption of extreme ultraviolet (EUV) lithography, which is becoming the cornerstone for sub-5nm and future 2nm process technologies. Leading manufacturers such as ASML Holding are expanding their EUV system portfolios, with next-generation High-NA (numerical aperture) EUV tools expected to enter mass production by 2025–2026. These systems enable finer patterning, improved resolution, and greater throughput, directly supporting advanced logic and memory chip fabrication.

Another key trend is the integration of artificial intelligence (AI) and machine learning (ML) into photolithography equipment. AI-driven process control and predictive maintenance are being embedded to optimize exposure parameters, reduce defects, and minimize downtime. Companies like Canon Inc. and Nikon Corporation are investing in smart lithography platforms that leverage real-time data analytics for adaptive process tuning, which is crucial for yield enhancement as device geometries shrink.

Materials innovation is also shaping equipment manufacturing. The shift to new photoresists and pellicle materials compatible with EUV wavelengths is prompting equipment makers to redesign subsystems for contamination control and improved optics longevity. This is particularly relevant as the industry moves toward high-volume manufacturing (HVM) of EUV-based chips, where uptime and tool reliability are paramount.

Additionally, sustainability and energy efficiency are emerging as critical considerations. Photolithography tools, especially EUV systems, are energy-intensive. Manufacturers are developing advanced cooling systems, energy recovery solutions, and modular designs to reduce the carbon footprint and operational costs of fabs. This aligns with broader industry commitments to environmental responsibility, as highlighted by initiatives from Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung Electronics.

Finally, supply chain resilience is influencing manufacturing strategies. The geopolitical landscape and recent disruptions have led equipment makers to diversify sourcing, localize critical component production, and invest in digital twins for remote diagnostics and support. These measures aim to ensure uninterrupted delivery and service of photolithography systems worldwide, supporting the semiconductor industry’s growth through 2030.

Competitive Landscape and Leading Players

The competitive landscape of the photolithography equipment manufacturing market in 2025 is characterized by high technological barriers, significant capital requirements, and a concentrated group of leading players. The industry is dominated by a few global companies, each leveraging proprietary technologies and extensive R&D investments to maintain their market positions. The photolithography process is critical for semiconductor fabrication, and as chip geometries shrink to sub-5nm nodes, the demand for advanced equipment—particularly extreme ultraviolet (EUV) lithography—has intensified.

- ASML Holding NV: The undisputed leader in the photolithography equipment market, ASML Holding NV holds a near-monopoly in EUV lithography systems, which are essential for manufacturing the most advanced semiconductor nodes. In 2024, ASML accounted for over 90% of the EUV market share, supplying critical equipment to major foundries such as TSMC, Samsung, and Intel. The company’s technological edge is reinforced by its complex supply chain and exclusive partnerships for key components like high-precision optics and light sources.

- Nikon Corporation: Nikon Corporation remains a significant player in deep ultraviolet (DUV) lithography, serving memory and logic chip manufacturers, particularly in Japan and parts of Asia. While Nikon has lagged in EUV development, it continues to innovate in immersion DUV systems and maintains a strong presence in legacy and mid-range semiconductor production.

- Canon Inc.: Canon Inc. focuses on i-line and KrF lithography systems, catering to mature process nodes and specialty applications such as image sensors and power devices. Canon’s market share is concentrated in niche segments, and the company has invested in cost-effective solutions for emerging markets and smaller foundries.

Barriers to entry in this market remain formidable due to the complexity of photolithography technology, the need for precision engineering, and the extensive intellectual property portfolios held by incumbents. New entrants face challenges in both technological development and customer trust, as semiconductor manufacturers require proven reliability and long-term support. The competitive dynamics are further shaped by ongoing trade tensions and export controls, particularly affecting the supply of advanced lithography systems to China and other regions (SEMI).

Looking ahead to 2025, the competitive landscape is expected to remain stable, with incremental innovation and capacity expansion by the leading players, while smaller firms and new entrants focus on specialized or regional markets.

Market Growth Forecasts and CAGR Analysis (2025–2030)

The photolithography equipment manufacturing market is poised for robust growth between 2025 and 2030, driven by escalating demand for advanced semiconductor devices, the proliferation of AI and 5G technologies, and the ongoing transition to smaller process nodes. According to projections by Gartner, the global semiconductor industry is expected to rebound strongly after a cyclical downturn, with capital expenditures on wafer fabrication equipment—including photolithography tools—rising steadily from 2025 onward.

Market research from MarketsandMarkets forecasts the photolithography equipment market to achieve a compound annual growth rate (CAGR) of approximately 7–8% during the 2025–2030 period. This growth is underpinned by the increasing adoption of extreme ultraviolet (EUV) lithography systems, which are essential for manufacturing chips at 5nm and below. Leading manufacturers such as ASML Holding are expected to expand production capacity to meet surging demand from foundries and integrated device manufacturers (IDMs).

Regionally, Asia-Pacific will continue to dominate market share, propelled by aggressive investments in semiconductor fabrication plants in China, Taiwan, and South Korea. According to SEMI, these countries are set to account for over 60% of global photolithography equipment installations by 2030. North America and Europe are also projected to see above-average growth rates, supported by government incentives and strategic initiatives to localize semiconductor manufacturing.

Technological advancements will further accelerate market expansion. The transition from deep ultraviolet (DUV) to EUV lithography is expected to drive average selling prices (ASPs) higher, contributing to overall market value growth. Additionally, the emergence of next-generation lithography techniques, such as high-NA EUV, will open new revenue streams for equipment manufacturers.

In summary, the photolithography equipment manufacturing market is set for sustained, high-single-digit CAGR growth through 2030, with market value projected to surpass $20 billion by the end of the forecast period, according to Market Research Future. The sector’s trajectory will be shaped by technological innovation, regional capacity expansions, and the relentless drive toward advanced semiconductor nodes.

Regional Market Analysis: Opportunities and Hotspots

The global photolithography equipment manufacturing market is witnessing dynamic regional shifts, with Asia-Pacific, North America, and Europe emerging as key hotspots for growth and investment in 2025. The Asia-Pacific region, led by Taiwan, South Korea, Japan, and increasingly China, continues to dominate due to its robust semiconductor fabrication ecosystem and aggressive government incentives. Taiwan’s TSMC and South Korea’s Samsung Electronics are expanding advanced node production, driving demand for cutting-edge extreme ultraviolet (EUV) and deep ultraviolet (DUV) photolithography systems. China, propelled by its “Made in China 2025” initiative, is investing heavily in domestic equipment manufacturing, with companies like SMIC and NAURA Technology Group ramping up local capabilities, though they still rely on imports for the most advanced tools.

North America, particularly the United States, is experiencing a resurgence in semiconductor manufacturing, fueled by the CHIPS and Science Act and significant investments from Intel and TSMC’s Arizona fab. This is creating new opportunities for photolithography equipment suppliers, especially as the U.S. seeks to localize supply chains and reduce dependence on Asian imports. The region’s focus on advanced logic and memory chip production is expected to boost demand for next-generation EUV systems, with ASML remaining the primary supplier globally.

- Asia-Pacific: Accounts for over 70% of global semiconductor fabrication capacity, with ongoing fab expansions and government-backed R&D initiatives (SEMI).

- North America: Projected to see double-digit growth in equipment spending through 2025, driven by new fab construction and reshoring efforts (SEMI).

- Europe: The European Union’s European Chips Act is catalyzing investments in local manufacturing, with Infineon Technologies and STMicroelectronics expanding capacity and fostering demand for advanced photolithography tools.

Emerging hotspots include Southeast Asia, where countries like Singapore and Malaysia are attracting new investments in backend and specialty semiconductor manufacturing, creating secondary demand for mid-range photolithography equipment. Overall, regional opportunities in 2025 are closely tied to government policy, supply chain localization, and the race for technological leadership in advanced semiconductor nodes.

Future Outlook: Emerging Applications and Investment Priorities

The future outlook for photolithography equipment manufacturing in 2025 is shaped by the convergence of technological innovation, evolving semiconductor applications, and shifting investment priorities. As the semiconductor industry pushes toward sub-2nm process nodes, demand for advanced photolithography tools—particularly extreme ultraviolet (EUV) systems—continues to surge. Leading manufacturers are intensifying R&D to address the technical challenges of higher resolution, overlay accuracy, and throughput, with ASML Holding maintaining its dominance in EUV technology and expanding its product roadmap to support next-generation chip designs.

Emerging applications in artificial intelligence (AI), high-performance computing (HPC), automotive electronics, and 5G/6G communications are driving the need for more sophisticated and miniaturized integrated circuits. This, in turn, is accelerating the adoption of advanced photolithography equipment capable of supporting complex multi-patterning and 3D integration techniques. The automotive sector, for instance, is expected to be a significant growth driver, as demand for advanced driver-assistance systems (ADAS) and autonomous vehicle technologies requires high-density, low-power chips manufactured with cutting-edge lithography processes (SEMI).

Investment priorities in 2025 are expected to focus on:

- Scaling EUV Capacity: Major foundries and integrated device manufacturers (IDMs) are ramping up capital expenditures to secure EUV systems, with TSMC, Samsung Electronics, and Intel Corporation leading the charge in expanding advanced node production.

- Development of High-NA EUV: The transition to high numerical aperture (High-NA) EUV is a key investment area, promising further resolution improvements and enabling sub-2nm manufacturing (Gartner).

- Supply Chain Resilience: Geopolitical tensions and supply chain disruptions have prompted increased investment in domestic manufacturing capabilities and strategic partnerships, particularly in the US, Europe, and East Asia (SEMI).

- Green Manufacturing: Sustainability is emerging as a priority, with equipment makers investing in energy-efficient systems and eco-friendly process chemicals to meet regulatory and customer demands (ASML Holding).

Overall, the photolithography equipment manufacturing sector in 2025 is poised for robust growth, underpinned by relentless innovation, expanding end-use applications, and strategic investments aimed at maintaining technological leadership and supply chain security.

Challenges, Risks, and Strategic Opportunities

The photolithography equipment manufacturing sector faces a complex landscape of challenges, risks, and strategic opportunities as it moves into 2025. The industry is characterized by high capital intensity, rapid technological evolution, and a concentrated supplier base, all of which shape the competitive dynamics and future growth prospects.

One of the foremost challenges is the escalating cost and complexity of developing next-generation photolithography systems, particularly extreme ultraviolet (EUV) lithography. The R&D investment required for EUV tools is immense, with leading manufacturers such as ASML Holding reporting R&D expenditures exceeding €3 billion annually. This creates high barriers to entry and limits the number of viable competitors, increasing supply chain vulnerability and customer dependency on a handful of suppliers.

Supply chain risks have become more pronounced due to geopolitical tensions and export controls, especially between the US, China, and the EU. Restrictions on the export of advanced photolithography equipment to certain markets, notably China, have impacted revenue streams and forced manufacturers to reassess their global strategies. For instance, Nikkei Asia reports that export bans on EUV systems have led Chinese chipmakers to accelerate domestic R&D, potentially fostering new regional competitors in the long term.

Technological risks are also significant. The transition to sub-2nm process nodes demands unprecedented precision and reliability from photolithography tools. Any delays or failures in delivering these capabilities can result in lost market share, as semiconductor foundries are under pressure to meet the demands of AI, 5G, and high-performance computing markets. Furthermore, the need for highly specialized components, such as high-numerical-aperture lenses and advanced light sources, exposes manufacturers to bottlenecks and quality control issues.

Despite these challenges, strategic opportunities abound. The global push for semiconductor self-sufficiency, particularly in the US, EU, and Asia, is driving significant public and private investment in new fabs and equipment. According to SEMI, global fab equipment spending is projected to surpass $100 billion in 2025, with photolithography tools representing a substantial share. Manufacturers that can innovate in areas such as multi-patterning, maskless lithography, and process automation stand to capture new market segments and diversify their revenue streams.

In summary, while photolithography equipment manufacturing in 2025 is fraught with risks related to cost, supply chain, and technology, it also presents robust opportunities for those able to adapt and innovate in a rapidly evolving semiconductor ecosystem.

Sources & References

- ASML Holding

- Canon Inc.

- Nikon Corporation

- Canon Inc.

- MarketsandMarkets

- Market Research Future

- SMIC

- NAURA Technology Group

- European Chips Act

- Infineon Technologies

- STMicroelectronics

- Nikkei Asia