Table of Contents

- Executive Summary: 2025 Market Snapshot & Key Findings

- Technology Overview: Fundamentals of Ultrafast Terahertz Lithography

- Recent Breakthroughs: Innovations in Terahertz Source & Control

- Leading Manufacturers & Industry Initiatives (e.g., thzsystems.com, ieee.org)

- Applications: From Semiconductor Microfabrication to Bioengineering

- Competitive Landscape: Major Players and Strategic Partnerships

- Economic Impact & Market Projections Through 2030

- Challenges & Risks: Technical Hurdles and Industry Adoption Barriers

- Regulatory, Standardization, and IP Trends (Referencing ieee.org)

- Future Outlook: Emerging Opportunities and Next-Gen Roadmap

- Sources & References

Executive Summary: 2025 Market Snapshot & Key Findings

Ultrafast Terahertz (THz) Lithography Fabrication is poised to make significant strides in 2025, marking a pivotal year for this rapidly evolving sector. The technology leverages ultrashort THz pulses to enable sub-micron and potentially nanometer-scale patterning, offering transformative potential for semiconductor manufacturing, photonics, and advanced materials. In 2025, momentum is driven by both technological breakthroughs and the increasing need for next-generation lithography methods to address the limitations of traditional photolithography.

Key players in the semiconductor and advanced manufacturing sectors, such as ASML and Canon, are actively exploring and developing high-frequency lithography solutions to complement and eventually surpass existing extreme ultraviolet (EUV) methods. While commercial-scale THz lithography systems are not yet mainstream, 2025 sees advanced prototypes and pilot production lines in select R&D environments. Notably, collaboration between equipment manufacturers, chipmakers, and research institutions is intensifying to accelerate the path to commercialization.

Industry data from leading suppliers and industry groups indicates that the demand for smaller, faster, and more energy-efficient integrated circuits is propelling investment in ultrafast lithography. The THz band’s unique properties—such as high photon energy and the ability to penetrate materials opaque to visible and UV light—facilitate new possibilities in direct-write and maskless lithography, enabling flexible and rapid prototyping. As of 2025, pilot programs are focused on improving resolution, throughput, and process stability, with some systems achieving feature sizes below 100 nm, rivaling or exceeding current EUV capabilities.

Significant R&D initiatives are also underway in Asia, Europe, and North America, with consortia including organizations like SEMI and institutions partnering with industry leaders to develop standards, interoperability protocols, and scalable manufacturing processes. Equipment suppliers are working closely with materials companies to refine THz-transparent resists and substrates tailored for this new regime.

Looking ahead to the next few years, the outlook for ultrafast THz lithography is optimistic. Experts project initial commercial deployments in specialized markets—such as quantum computing, photonics, and advanced sensors—before broader adoption in mainstream semiconductor manufacturing. As technology matures, the sector is expected to see increased investment, further integration into advanced fab lines, and ongoing competition among established lithography giants and emerging technology firms. The convergence of ultrafast THz sources, precision optics, and adaptive software is set to define the competitive landscape through 2025 and beyond.

Technology Overview: Fundamentals of Ultrafast Terahertz Lithography

Ultrafast terahertz lithography fabrication is an emerging technology that leverages the unique properties of terahertz (THz) radiation—electromagnetic waves with frequencies from 0.1 to 10 THz—for the rapid patterning and structuring of materials at micro- and nanoscale resolutions. Unlike conventional lithography, which often relies on ultraviolet (UV) or electron beams, terahertz lithography exploits the distinctive interaction between THz pulses and matter, enabling new regimes of resolution, speed, and selectivity.

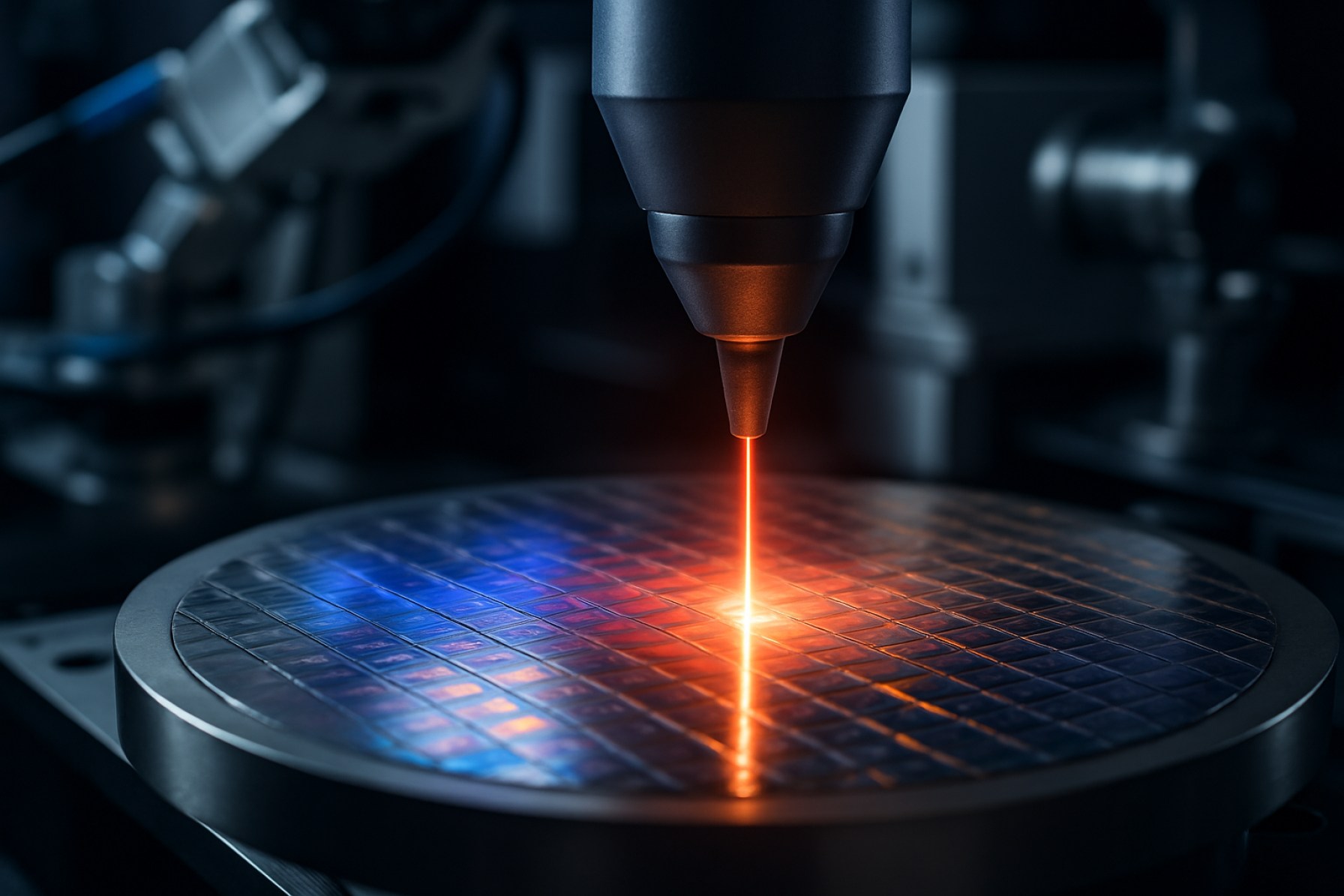

Fundamentally, ultrafast terahertz lithography operates by delivering high-intensity, ultrashort THz pulses (often from femtosecond lasers) onto photoresist-coated substrates. Through nonlinear absorption and multiphoton processes, these pulses drive localized chemical transformations in the resist, facilitating pattern development with features potentially below the diffraction limit of visible light. The extremely short pulse durations (typically <100 femtoseconds) minimize heat diffusion, allowing for high-precision patterning without damaging sensitive substrates or adjacent features.

By 2025, advances in both THz source generation and beam delivery systems are enabling more practical implementations in academic and industrial settings. Companies such as Menlo Systems and TOPTICA Photonics are commercializing high-power, ultrafast THz generators and related instrumentation, directly supporting research and early-stage manufacturing applications. These systems now deliver reliable, tunable THz pulses for integration into lithographic workflows, with recent demonstrations achieving feature sizes down to the low hundreds of nanometers—a significant step beyond traditional optical lithography limits.

Material compatibility is also rapidly expanding. Traditional photoresists have been reformulated to respond to THz frequencies, and novel classes of hybrid organic-inorganic resists are being tailored for THz-induced crosslinking or ablation, increasing process flexibility. Equipment suppliers like Thorlabs are responding by developing optics, waveguides, and positioning systems optimized for ultrafast THz applications.

In the immediate outlook (2025–2027), the sector is expected to focus on three main challenges: scaling throughput for industrial relevance, further reducing minimum achievable feature sizes, and integrating THz lithography with complementary processes such as nanoimprinting or direct-write techniques. As key players refine source efficiency and resist sensitivity, ultrafast terahertz lithography holds promise for next-generation semiconductor prototyping, advanced photonic device fabrication, and even biocompatible microstructure manufacturing. Ongoing collaborations between equipment manufacturers and semiconductor firms indicate a pathway toward pilot-scale production lines within the next few years, signaling a pivotal moment for the maturation of this disruptive technology.

Recent Breakthroughs: Innovations in Terahertz Source & Control

Ultrafast terahertz (THz) lithography fabrication has emerged as a transformative approach in micro- and nano-fabrication, leveraging the unique capabilities of intense, pulsed THz radiation for high-resolution patterning. Recent breakthroughs have been propelled by advances in THz source generation, beam control, and integration with lithographic platforms, with 2025 marking a pivotal year for the field.

Key developments hinge on the maturation of compact, high-power THz sources. In 2024 and 2025, several leading manufacturers have commercialized table-top systems based on optical rectification and quantum cascade laser (QCL) technology, offering pulse energies sufficient for direct lithography and maskless pattern transfer. Companies such as TOPTICA Photonics and Menlo Systems are at the forefront, providing tunable femtosecond and picosecond THz sources that enable sub-micron feature definition. Their systems facilitate rapid exposure times, crucial for scaling throughput in industrial prototyping and R&D environments.

Control and shaping of THz beams have also advanced, with dynamic beam steering and adaptive optics now integrated into commercial lithography setups. These innovations allow precise modulation of intensity profiles and spatial resolution, essential for complex patterning on flexible substrates and 3D surfaces. Notably, TOPTICA Photonics and Menlo Systems have incorporated real-time beam diagnostics and feedback systems for robust process control, reducing alignment errors and variability between runs.

A significant milestone in 2025 is the demonstration of direct-write THz lithography for functional electronic and photonic devices, with feature sizes reaching below 500 nm. This is made possible by the synergy between high-field THz sources and novel photoresist materials engineered for strong absorption in the THz regime. Collaborative research projects involving equipment providers and materials developers—such as partnerships with TOPTICA Photonics—are accelerating the adoption of THz lithography in semiconductor prototyping and micro-optics fabrication.

Looking ahead, the next few years are expected to witness further uptake of ultrafast THz lithography, particularly in rapid prototyping, flexible electronics, and low-damage processing of sensitive substrates. The roadmap includes integrating AI-driven pattern recognition and real-time process optimization, as well as scaling up source power for larger-area fabrication. With industry leaders actively commercializing and refining these technologies, ultrafast THz lithography is poised to become a mainstay in advanced manufacturing workflows by the late 2020s.

Leading Manufacturers & Industry Initiatives (e.g., thzsystems.com, ieee.org)

Ultrafast terahertz (THz) lithography is rapidly gaining momentum as a frontier nanofabrication technique, promising sub-micron resolution and high-throughput patterning capabilities. As of 2025, a handful of specialized manufacturers and industry consortia have begun to shape the commercialization and standardization landscape for this technology. Early market activity is focused on the development of THz sources, beam delivery optics, and integrated lithography platforms.

Leading the charge, THz Systems has introduced advanced THz pulse generators and patterning modules specifically designed for ultrafast lithography processes. Their systems are being adopted in pilot lines for semiconductor prototyping, with notable collaborations in both Europe and Asia. Alongside hardware, THz Systems is investing in control software that optimizes exposure parameters for emerging resist materials compatible with THz radiation.

Standardization and best practices are being actively discussed within international bodies such as the IEEE. In 2024–2025, the IEEE Photonics Society has convened working groups to address THz lithography system interoperability, safety protocols, and performance benchmarking. Early drafts of technical standards are expected to be available by late 2025, facilitating broader industry adoption and supporting the integration of THz lithography into existing semiconductor manufacturing environments.

Supplier innovation is also evident from component manufacturers. Companies like Menlo Systems are developing mode-locked lasers and femtosecond amplifiers tailored for THz generation, while TOPTICA Photonics is advancing tunable THz sources and detectors. Both firms report increasing demand from research labs and pilot manufacturing sites exploring the scalability of ultrafast THz lithography.

Looking ahead to the next few years, the outlook for ultrafast THz lithography is highly promising. Industry initiatives are converging towards multi-site demonstration projects, with several major semiconductor foundries reportedly evaluating prototype systems for advanced packaging and high-density interconnects. Successful integration will depend on continued advances in THz source efficiency, resist chemistry, and precision optics, as well as the establishment of robust standards. The collaboration between manufacturers, standards bodies, and end-users will be crucial in accelerating the transition of ultrafast THz lithography from niche research to industrial deployment.

Applications: From Semiconductor Microfabrication to Bioengineering

Ultrafast terahertz (THz) lithography fabrication is rapidly emerging as a disruptive technology for micro- and nano-scale patterning, with significant implications for applications ranging from semiconductor device manufacturing to advanced bioengineering. As of 2025, several leading research centers and industry players are accelerating the integration of THz-based lithography into mainstream fabrication processes, targeting the limitations of traditional optical lithography in terms of resolution, speed, and material compatibility.

In the semiconductor sector, the ever-increasing demand for miniaturization and higher throughput drives the exploration of new lithographic techniques. Ultrafast THz pulses, with their sub-picosecond duration and unique interaction with materials, enable patterning below the diffraction limit of visible and ultraviolet light. This translates to smaller feature sizes and improved process control. Companies such as ASML, a global leader in lithography systems, are actively monitoring the progress of next-generation lithography, including THz-driven approaches, as part of their roadmap toward sub-2 nm technologies. Early-stage pilot lines incorporating THz exposure modules have demonstrated the potential to reduce line edge roughness and enable selective material processing, critical for advanced logic and memory devices.

Beyond semiconductors, ultrafast THz lithography is gaining traction in bioengineering applications. The non-ionizing nature of THz radiation and its tunable photon energy allow for gentle processing of sensitive biomaterials and polymers. Research collaborations with institutions such as the National Institute of Standards and Technology are investigating the use of THz lithography for fabricating microfluidic devices and biosensors with complex geometries, which are difficult to achieve using conventional methods. These platforms are expected to unlock new capabilities in point-of-care diagnostics and organ-on-chip technologies over the next few years.

Looking ahead, the outlook for ultrafast THz lithography fabrication is promising. Ongoing investments in THz source development, particularly from firms like TRUMPF—a major supplier of industrial laser systems—are addressing challenges around power scalability and process integration. In parallel, material suppliers are developing tailored photoresists and substrates optimized for THz exposure, further enhancing compatibility and throughput. As these technical hurdles are progressively overcome, industry experts anticipate the commercialization of THz lithography modules for specialized semiconductor and biomedical manufacturing by the late 2020s.

In summary, ultrafast THz lithography is poised to reshape the landscape of both semiconductor microfabrication and bioengineering, offering a pathway to finer features, higher speeds, and broader material versatility. The coming years will likely witness pilot deployments and early commercial systems, laying the groundwork for widespread adoption across multiple high-impact sectors.

Competitive Landscape: Major Players and Strategic Partnerships

The competitive landscape of ultrafast terahertz (THz) lithography fabrication is characterized by a mix of established photonics giants, innovative startups, and strategic collaborations bridging industry and academia. As of 2025, the field is in a crucial phase of transition from laboratory-scale demonstrations toward commercial-scale equipment and process integration, with several key players shaping its trajectory.

Major Industry Players

- TRUMPF: Recognized for its leadership in industrial lasers and photonics, TRUMPF has expanded its R&D efforts in ultrafast laser systems applicable to THz-driven lithography. The company’s expertise in high-power, ultrafast pulse generation is positioning it as a potential early supplier of THz lithography modules for advanced semiconductor manufacturing.

- Hamamatsu Photonics: Hamamatsu Photonics has invested heavily in THz component research, including sources and detectors crucial for lithography alignment and process control. Their ongoing partnerships with academic institutions are accelerating the development of scalable THz systems.

- Toptica Photonics: Known for its specialized ultrafast laser systems, Toptica Photonics has begun collaborating with semiconductor toolmakers to adapt its femtosecond and THz source technology for next-generation lithography pilot lines.

- Applied Materials: Although traditionally focused on conventional lithography and process tools, Applied Materials has recently signaled interest in integrating THz-driven techniques into its process control and metrology portfolio, exploring partnerships with photonics specialists.

Strategic Partnerships and Collaborations

- Several consortia, often involving leading research universities and national labs, have formed to bridge the gap between fundamental THz science and industrial application. For instance, partnerships between TRUMPF and European research institutes are focusing on high-throughput THz lithography demonstrations.

- Equipment makers are increasingly collaborating with wafer foundries and materials suppliers to validate THz lithography’s compatibility with existing process flows. Hamamatsu Photonics and Toptica Photonics are active in multi-party pilot projects aiming for commercial viability by the late 2020s.

Outlook

Over the next several years, the competitive landscape is expected to consolidate as proof-of-concept demonstrations mature into pilot-scale production. Partnerships will likely deepen, with photonics suppliers, semiconductor toolmakers, and foundries working together to resolve integration challenges. As standardization efforts and early adopter programs emerge, collaboration between industry leaders like TRUMPF, Hamamatsu Photonics, and Applied Materials will be central to transitioning ultrafast THz lithography from a technological promise to a commercial reality.

Economic Impact & Market Projections Through 2030

Ultrafast Terahertz (THz) lithography fabrication is poised to redefine the landscape of advanced manufacturing, with significant economic ramifications expected by 2030. As of 2025, the field is transitioning from academic research to early-stage commercial deployment, influenced by the rising demand for next-generation semiconductor devices, photonic circuits, and high-speed electronics. The ability of THz lithography to achieve nanometer-scale resolution at unprecedented speeds positions it as a disruptive alternative to conventional optical and electron-beam lithography methods.

Several industry leaders in semiconductor equipment and photonics have already initiated pilot programs or announced collaborations to advance THz lithography. For example, ASML, a global leader in photolithography systems, has signaled interest in evaluating and potentially integrating ultrafast THz sources for future node development. Similarly, TRUMPF, known for its industrial laser technologies, is investing in terahertz technology platforms, exploring their application in high-precision manufacturing processes.

The economic impact through 2030 hinges on the maturation of the technology and its adoption rate across critical sectors such as semiconductor manufacturing, microelectromechanical systems (MEMS), and photonic component fabrication. The promise of THz lithography lies in its capability to lower production costs, increase throughput, and enable highly complex nanostructures, potentially reducing the capital intensity and environmental footprint of chip fabrication. Industry sources project that if THz lithography achieves even partial penetration into the advanced node market (e.g., sub-5 nm semiconductors), the global market for related equipment and services could approach several billion USD annually by the late 2020s.

Key economic drivers include the exponential growth in demand for AI accelerators, quantum devices, and high-frequency photonic components. Leading technology manufacturers, including Intel and TSMC, are actively monitoring developments in ultrafast lithography for potential integration into future fabrication roadmaps. Early adoption is likely to occur in specialized segments such as integrated photonics and advanced sensor manufacturing, where the flexibility and speed of THz processes offer immediate value.

Looking ahead, the economic outlook for ultrafast terahertz lithography fabrication will depend on continued investment in R&D, the establishment of reliable THz source suppliers, and the demonstration of consistent yield improvements at scale. Industry consortia and standards bodies, such as SEMI, are expected to play a vital role in facilitating interoperability and market adoption. By 2030, THz lithography could represent a foundational technology in the high-value semiconductor supply chain, contributing to both cost efficiencies and new product capabilities.

Challenges & Risks: Technical Hurdles and Industry Adoption Barriers

Ultrafast terahertz (THz) lithography fabrication, while promising unprecedented speed, precision, and energy efficiency in micro- and nano-manufacturing, faces a set of technical challenges and adoption barriers in 2025 and the immediate future. One of the foremost technical hurdles lies in the generation and control of high-intensity THz pulses with sufficient energy and stability for industrial-scale lithography. Although advances in solid-state THz sources and fiber laser systems are ongoing, scalable, cost-effective sources capable of delivering uniform beam profiles remain under development. For example, companies such as TeraView Limited and Menlo Systems are actively working on improving THz source reliability and integration, yet fully industrial-grade solutions are not widespread.

Another challenge is the development of suitable photoresists and materials that can interact efficiently with THz frequencies. Conventional photoresists optimized for UV or EUV lithography often exhibit poor sensitivity or resolution at THz wavelengths, necessitating extensive R&D in material science. This is compounded by the lack of standardized process recipes and etching chemistries compatible with THz patterning techniques. The adaptation of existing cleanroom infrastructure and process controls to accommodate new THz systems further complicates integration into established semiconductor fabrication lines.

From an industry adoption standpoint, risk aversion in the highly capital-intensive semiconductor and photonics sectors slows down the uptake of THz lithography. Incumbent processes—especially deep ultraviolet (DUV) and extreme ultraviolet (EUV) lithography—are mature, with significant ecosystem investments from major players like ASML. Shifting to THz-based approaches would require not only new capital expenditure but also a retooling of workflows, retraining of personnel, and assurance of yield and reliability over several technology generations. In addition, interoperability with existing process nodes and downstream wafer handling systems presents non-trivial engineering challenges.

There are also safety, regulatory, and standardization issues. While THz radiation is non-ionizing and thus safer than X-rays, comprehensive industrial standards for safe operation and emission levels are still evolving through bodies such as the SEMI and IEEE. Manufacturers must demonstrate compliance and secure certifications before widespread deployment, adding to time-to-market delays.

Looking ahead, ongoing collaborations between THz component suppliers, semiconductor manufacturers, and industry consortia are expected to address many of these obstacles over the next few years. However, the timeline for mainstream adoption remains uncertain, hinging on breakthroughs in source technology, materials, and scalable integration strategies.

Regulatory, Standardization, and IP Trends (Referencing ieee.org)

As ultrafast terahertz (THz) lithography fabrication transitions from laboratory-scale demonstrations to pre-commercial stages, regulatory, standardization, and intellectual property (IP) trends are emerging as pivotal areas shaping its industrial adoption from 2025 onward. The unique combination of sub-picosecond time resolution and non-ionizing, high-frequency THz radiation has necessitated fresh regulatory and standardization considerations distinct from those governing traditional photolithography and electron-beam techniques.

On the regulatory front, safety and emission standards are a primary focus for governmental agencies and professional bodies. Given that THz sources can bridge optical and electronic regimes, their use in lithography demands assessment regarding electromagnetic interference (EMI), workplace exposure limits, and equipment certification. As of 2025, collaborative efforts between international standards organizations such as the IEEE and national regulatory bodies are underway to draft comprehensive guidelines for THz system emissions, facility shielding requirements, and personnel safety protocols. These guidelines are expected to align with existing frameworks for electromagnetic radiation but with new parameters reflecting the unique operational frequencies and intensities in THz lithography.

Standardization activities are accelerating, particularly in defining test methodologies, process benchmarks, and interoperability for THz-based lithography platforms. The IEEE has initiated working groups focused on THz device characterization, measurement accuracy, and system integration. Draft standards related to THz lithography are anticipated for review within the next 1–2 years, providing a foundation for cross-vendor compatibility and quality assurance in production environments. Industry consortia are also collaborating with semiconductor equipment manufacturers to develop open reference architectures, enabling streamlined adoption by fabs seeking to incorporate ultrafast THz patterning capabilities.

Intellectual property activity in ultrafast THz lithography has surged, with an increasing number of patent filings by both established semiconductor equipment providers and emerging photonics startups. The patent landscape in 2025 is characterized by filings covering THz source generation, pulse shaping, beam steering, and integration with resist materials, as well as broader system-level innovations. Major industry players are actively seeking cross-licensing agreements and patent pools to mitigate risks of litigation as the technology matures. This collaborative approach is expected to accelerate commercialization and foster a more open ecosystem, in line with the precedent set by earlier lithographic technology transitions.

Looking ahead, regulatory harmonization and robust standardization will be critical to ensuring safe, reliable, and interoperable deployment of ultrafast THz lithography. As industry adoption scales, close coordination between regulatory bodies, standards organizations such as the IEEE, and IP stakeholders will be essential to unlock the full potential of this next-generation fabrication technology.

Future Outlook: Emerging Opportunities and Next-Gen Roadmap

Ultrafast terahertz (THz) lithography fabrication—leveraging the unique properties of THz electromagnetic pulses for patterning materials—remains an emerging field with significant promise for revolutionizing next-generation micro- and nanofabrication. As of 2025, rapid advances in THz source technology, material compatibility, and process control are converging to unlock new opportunities in semiconductor manufacturing, advanced photonics, and flexible electronics.

Current momentum is driven by breakthroughs in ultrafast THz pulse generation with higher peak powers and tunable frequencies, offering sub-picosecond time resolution. Companies such as TeraView and Menlo Systems are commercializing compact, high-power THz sources and measurement systems, which are critical for enabling industrial-scale lithography. These advances are making it feasible to explore THz-induced nonthermal ablation and selective material processing, which can potentially circumvent traditional diffraction limits and thermal damage concerns found in UV and EUV lithography.

Prototype THz lithography systems are already demonstrating sub-100 nm feature patterning on polymers and certain semiconductors, with research collaborations focusing on scaling throughput and achieving process repeatability. Industry consortia and research institutes—including imec and CSEM—are actively investigating THz-driven direct-write approaches and hybrid processes (combining THz with laser or electron beam techniques) for application-specific device fabrication. In parallel, major semiconductor equipment manufacturers are monitoring these developments for potential integration into future roadmap nodes, particularly as EUV system costs and complexity rise.

Looking toward the next several years, the outlook for ultrafast THz lithography centers on a few pivotal milestones:

- Development of robust, high-repetition-rate THz sources compatible with cleanroom environments and industrial workflows.

- Expansion of processable materials, including novel 2D materials, flexible substrates, and biocompatible polymers, supported by partnerships with leading material suppliers such as Dow.

- Demonstration of viable process integration with existing CMOS and photonic device fabrication lines, with pilot programs expected to emerge by 2026-2027.

- Standardization efforts and the gradual establishment of metrology and process control frameworks, facilitated by industry bodies like SEMI.

While technical barriers remain—notably in throughput, mask alignment, and large-area uniformity—stakeholders anticipate that THz lithography could become a disruptive enabler for specialized, high-value applications. These include advanced sensors, quantum device fabrication, and ultra-rapid prototyping, positioning ultrafast THz lithography as a key contender within the next-gen semiconductor and microfabrication landscape through 2030 and beyond.